Preparation method and application of high-purity aluminum oxide

A technology of high-purity alumina and alumina, applied in the fields of alumina/hydroxide preparation, chemical instruments and methods, aluminate/alumina/aluminum hydroxide purification, etc., can solve the problem of reducing the content of metal element impurities, producing Corrosive acid gas, environmental pollution and other problems, to achieve the effect of high firing temperature, easy production operation and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

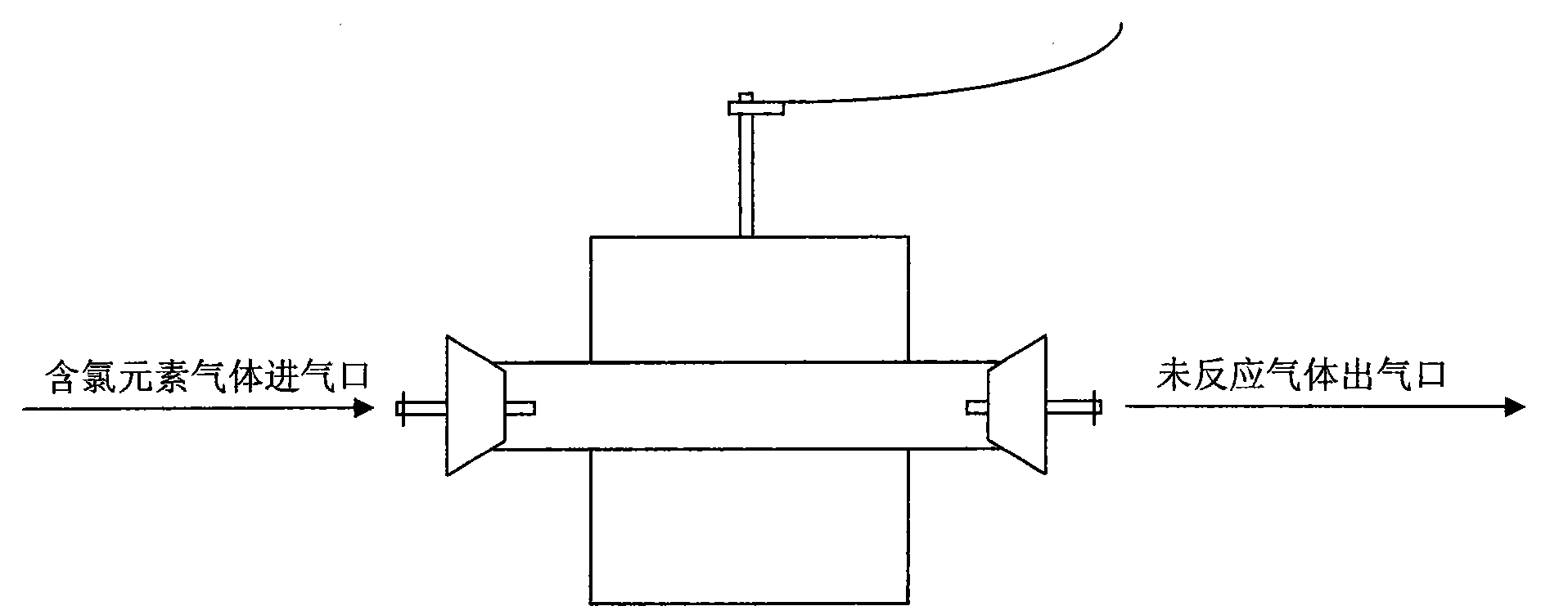

Image

Examples

Embodiment 1

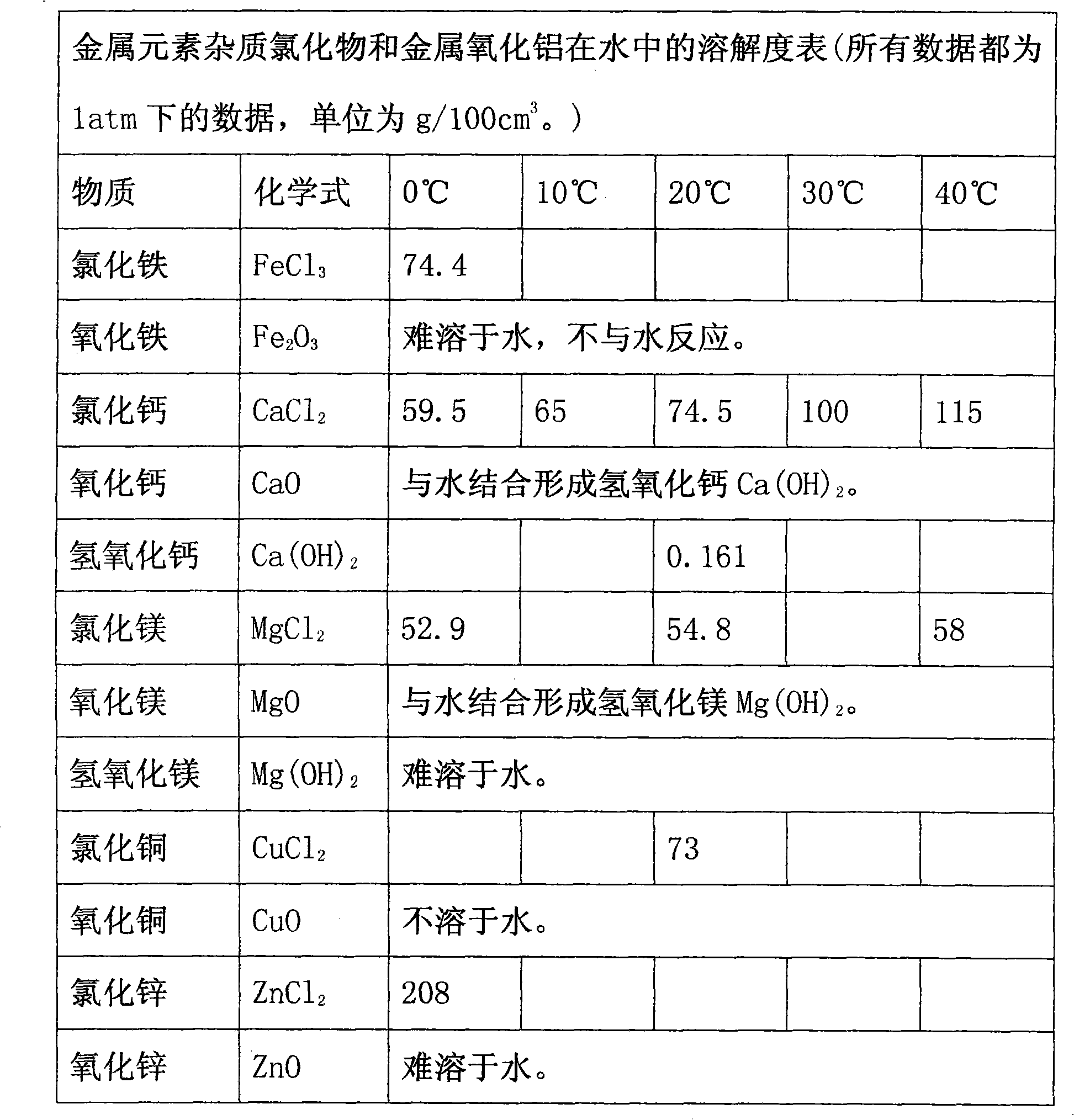

[0050] Put 150 grams of aluminum hydroxide with a metal element impurity content higher than 70ppm into the quartz glass tube, pass chlorine and nitrogen, the chlorine content is 40%, and heat the tube furnace to 600°C for 6 hours. Use pure water for the cooled solid After washing twice and drying, 148 grams of alumina was obtained, and the metal element impurity content was less than 10 ppm.

[0051] Test items

[0052] Magnesium

[0053] Using the prepared alumina as a raw material, using a bubble-growth single crystal furnace for crystal growth, a colorless and transparent sapphire crystal was obtained, and the dislocation density of the crystal lattice was 512 bars / cm 2 , The index of the product obtained meets the technical standards of light-emitting diode (LED) substrates.

Embodiment 2

[0055] Put 200g of aluminum hydroxide with metal element impurity content higher than 60ppm into the quartz glass tube, pass chlorine gas and air, the chlorine content is 80%, and heat the tube furnace to 800℃ for 12 hours to obtain 199g of aluminum oxide. The impurity content is less than 10ppm.

[0056] Test items

[0057] Nickel

[0058] Using the prepared alumina as a raw material, using a bubble-growth single crystal furnace for crystal growth, a colorless and transparent sapphire crystal is obtained, and the dislocation density of the crystal lattice is 547 bars / cm 2 , The index of the product obtained meets the technical standards of light-emitting diode (LED) substrates.

Embodiment 3

[0060] Put 450 grams of aluminum hydroxide with metal element impurity content higher than 110ppm into the corundum alumina tube, pass chlorine gas, the chlorine content is 100%, heat the tube furnace to 1000°C for 0.5 hours, and wash the cooled solid with pure water After drying, 446 g of alumina was obtained, and the metal element impurity content was less than 10 ppm.

[0061] Test items

[0062] Potassium

[0063] Using the prepared alumina as a raw material, using a bubble-growth single crystal furnace for crystal growth, a colorless and transparent sapphire crystal was obtained, and the dislocation density of the crystal lattice was 589 bars / cm 2 , The index of the product obtained meets the technical standards of light-emitting diode (LED) substrates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com