Method for preparing 2-amino-4-methylthio butyric acid by using recombinant nitrilase

A technology of methylthiobutyric acid and nitrilase, applied in the direction of microorganism-based methods, botanical equipment and methods, biochemical equipment and methods, etc., can solve the difficulties of crystallization and separation of methionine, incomplete conversion, and low activity of methioninase And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

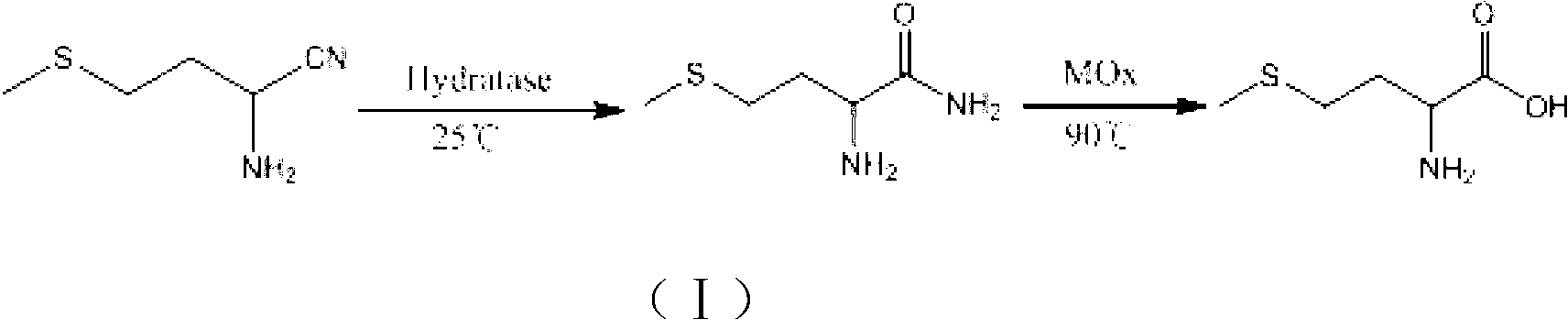

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1: Construction of prokaryotic expression plasmid of nitrilase gene

[0074] Using PCR technology, using the genomic DNA in CCTCC NO.M209044 of Acidovorax facilis (Acidovorax facilis) as a template (genome extraction kit from MP Company in the United States) as a template, and using the designed positive and negative primers for PCR amplification, the amplification system is shown in Table 1 As shown, the primers are as follows:

[0075] P1:5'-ATGGTTTCGTATAACAGCAAG-3'

[0076] P2:5'-CTACTTTGCTGGGACCGG-3'.

[0077] The PCR reaction system is:

[0078] Table 1 PCR amplification reaction system

[0079]

[0080]PCR reaction process: 94°C for 5min; 94°C for 45s, 55°C for 45s, 35 cycles; 72°C for 2min; 72°C for 10min.

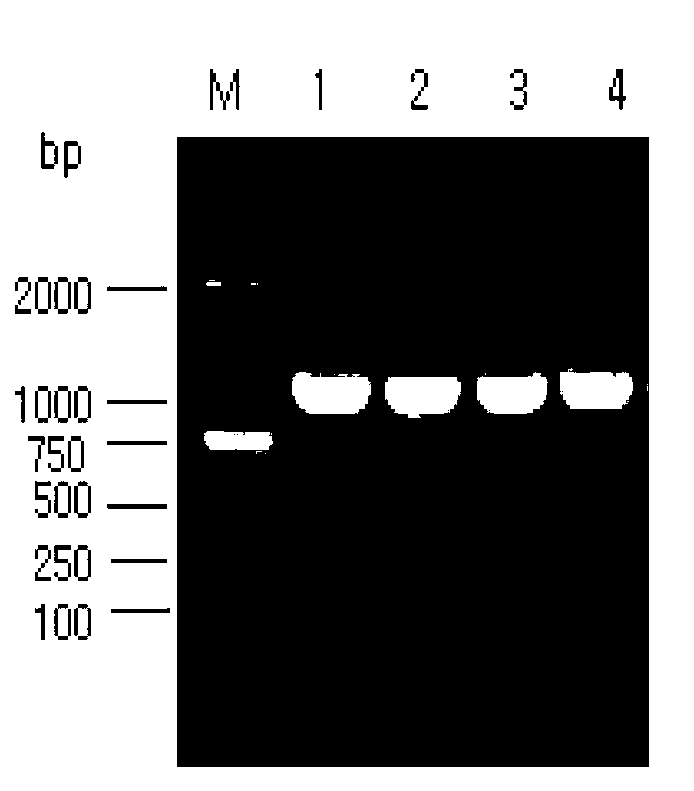

[0081] The amplified product is a 1121bp nitrilase gene sequence (SEQ ID NO.1).

[0082] Take 5 μL of PCR reaction solution and use 0.9% agarose gel electrophoresis for detection. First, heat the prepared 0.9% agarose gel in a microwave ove...

Embodiment 2

[0083] Embodiment 2 Contains the construction of the recombinant genetically engineered bacterium of nitrilase gene

[0084] The SEQ ID NO.1 sequence that obtains according to embodiment 1, and introduce BamHI and SalI restriction endonuclease cut site, utilize restriction endonuclease BamHI and SalI to process SEQ ID NO.1 sequence; Then with the same restriction endonuclease Dicer-digested expression vector pET-28b was ligated to obtain the recombinant expression plasmid pET-28b-NIT, and it was electrotransformed into Escherichia coli BL21 (DE3) to obtain recombinant genetically engineered bacteria E.coli BL21 (DE3) / pET -28b-NIT.

Embodiment 3

[0085] Example 3: Expression of the nitrilase gene

[0086] (1) Cells containing the nitrilase gene: Inoculate the recombinant engineering bacteria E.coli BL21(DE3) / pET-28b-NIT constructed by the method in Example 2 and containing the recombinant plasmid pET-28b-NIT into LB liquid medium (Containing 50 μg / ml kanamycin), cultured at 37°C for 12 hours to obtain seed liquid, and inoculated the seed liquid into fresh LB liquid medium containing 50 μg / ml kanamycin at an inoculation volume of 3% by volume Medium, cultivated at 37°C to the cell concentration (i.e. OD 600 ) is about 0.6~0.8, then add the inducer IPTG (final concentration is 0.2mM) to the above LB liquid medium, induce culture at 37°C for 8h, obtain the induction culture medium, and then centrifuge the induction culture medium at 4°C, 10000rpm After 10 minutes, the wet cells were collected to obtain wet cells containing nitrilase (that is, whole cells of recombinant E. coli), which were used as an enzyme source for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com