Method for preparing high-efficiency fluorine removal agent from solid wastes

A technology for solid waste and fluoride removal agent, which is applied in chemical instruments and methods, water/sludge/sewage treatment, adsorbed water/sewage treatment, etc. Complex preparation process and other problems, to achieve the effect of simple preparation process, resource utilization, and rich sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

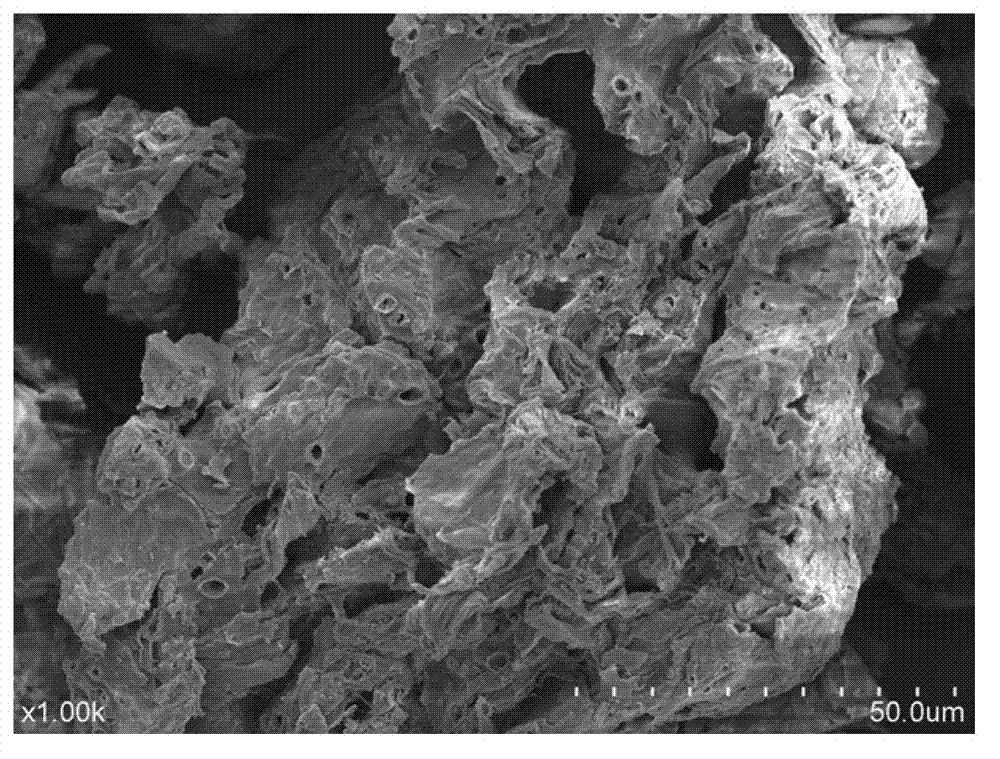

Image

Examples

Embodiment 1

[0023] A method for preparing a high-efficiency defluorinating agent by utilizing solid waste, the steps are as follows:

[0024] 1) Crush the discarded walnut shells into particles with a particle size of 1mm, wash with deionized water and remove impurities, dry at 105°C for 4 hours, and set aside;

[0025] 2) Crush egg shells into 0.1mm powder, add to acetic acid solution with a concentration of 25% by volume, the dosage ratio of egg shell powder and acetic acid solution is 1g / 20ml, carry out acid hydrolysis reaction at 100°C for 4 hours, and obtain soluble calcium solution;

[0026] 3) Immerse the walnut shell particles in the above soluble calcium solution for calcification treatment, the dosage ratio of walnut shell particles and soluble calcium solution is 1g:2mL, react at 20°C for 2.5h, dry at room temperature from 30°C to 10 The heating rate of ℃ / min is increased to 250℃, and oxidation pretreatment is carried out for 22 minutes;

[0027] 4) N at a flow rate of 10ml...

Embodiment 2

[0031] A method for preparing a high-efficiency defluorinating agent by utilizing solid waste, the steps are as follows:

[0032] 1) Crush the waste walnut shells and peanut shells into 0.15mm particles, mix them at a mass ratio of 1:1, wash with deionized water and remove impurities, dry at 105°C for 3 hours, and set aside;

[0033] 2) Wash and dry the shrimp shells and crush them into 0.1mm powder, add them to the citric acid solution with a concentration of 30% by volume, the dosage ratio of the shrimp shell powder to the citric acid solution is 1g / 25ml, and carry out the acid treatment at 110°C Hydrolysis for 6 hours to obtain a soluble calcium solution;

[0034] 3) Immerse the biomass particles in the above soluble calcium solution for calcification, the ratio of biomass particles to soluble calcium solution is 1g:2mL, react at 40°C for 3h, dry at room temperature from 30°C to 5°C The heating rate per minute was raised to 250°C, and the oxidation pretreatment was carried...

Embodiment 3

[0038] A method for preparing a high-efficiency defluorinating agent by utilizing solid waste, the steps are as follows:

[0039] 1) Crush the waste chestnut shells into particles with a particle size of 0.5mm, wash with deionized water and remove impurities, dry at 105°C for 3 hours, and set aside;

[0040] 2) Wash, dry and crush the eggshell into 0.25mm powder, add it to the propionic acid solution with a concentration of 40% by volume, the ratio of eggshell powder to propionic acid solution is 1g / 10ml, and carry out acid hydrolysis at 90°C React for 7 hours to prepare a soluble calcium solution;

[0041]3) Soak the chestnut shell particles in the above soluble calcium solution for calcification, the ratio of the amount of chestnut shell particles to the soluble calcium solution is 1g:2mL, react at 20°C for 2.5h, and dry at room temperature from 25°C to The temperature rise rate is 10°C / min to 300°C, and oxidation pretreatment is carried out for 27.5 minutes;

[0042] 4) N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com