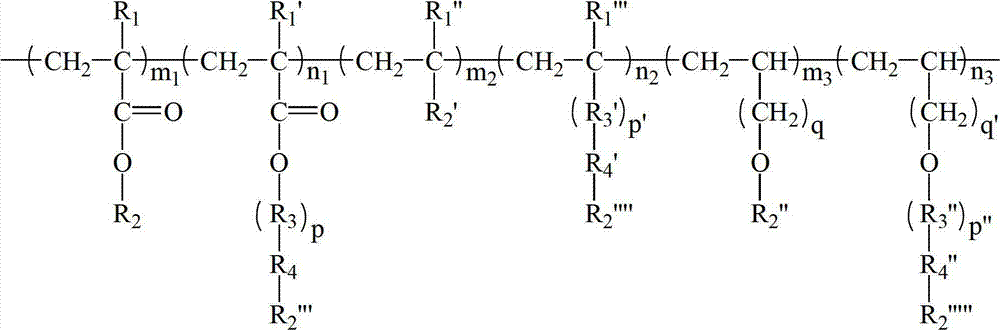

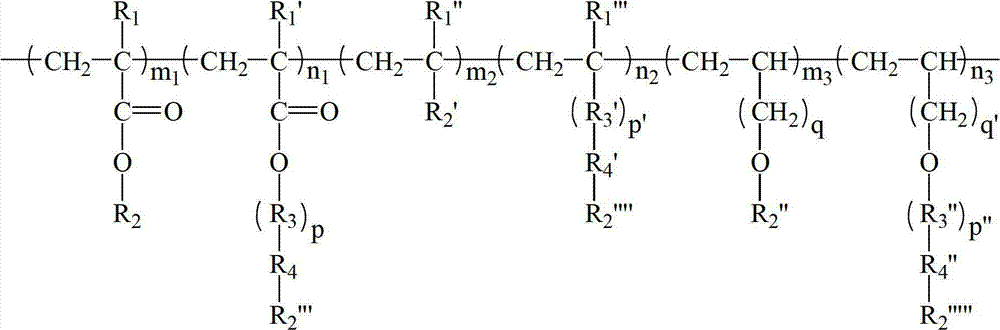

Ultraviolet cross-linking copolymer

A technology of cross-linked copolymers and ultraviolet light, which is applied in the field of copolymers and ultraviolet light cross-linked copolymers. It can solve the problems of high cross-linking temperature, yellowing resistance and migration resistance, and inconvenient construction on site. , to achieve the effect of maintaining stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 0.05 parts of 4-(2-acryloyloxy-methylene) benzophenone, 25 parts of styrene, 5 parts of methyl methacrylate, 25 parts of butyl acrylate, 5 parts of butyl methacrylate, isoacrylate 15 parts of octyl ester, 9.95 parts of vinyl acetate, 3 parts of benzyl acrylate, 10 parts of 2-hydroxypropyl methacrylate and 2 parts of acrylamide were used as the unsaturated monomer composition. Among them, 4-(2-acryloyloxy-methylene)benzophenone is a UV active monomer, and the others are monofunctional monomers.

[0032] In a reaction kettle with a stirrer, a temperature control device, a condensing device, a dropping device and a thermometer, the unsaturated monomer composition and 1 part of azobisisoheptanonitrile are used as the main raw materials, and the conventional bulk is carried out at 80 ° C. After polymerization, the product is dissolved in acetone, precipitated in methanol, washed and dried to obtain a solid ultraviolet cross-linked copolymer with a number average molecular we...

Embodiment 2

[0035] 3 parts of 4-methacryloxybenzophenone, 35 parts of methyl methacrylate, 20 parts of isobornyl acrylate, 12 parts of vinyl acetate, 10 parts of butyl acrylate, 5 parts of butyl methacrylate , 5 parts of isodecyl acrylate, 5 parts of methoxyethyl methacrylate, 2 parts of carboxyethyl acrylate and 3 parts of maleic acid as the unsaturated monomer composition. Among them, 4-methacryloyloxybenzophenone is an ultraviolet photoactive monomer, and the others are monofunctional monomers.

[0036] In a reaction kettle with a stirrer, temperature control device, condensing device, dropping device and thermometer, with unsaturated monomer composition and 1 part of azobisisobutyronitrile as the main raw materials, carry out conventional bulk at 80 ° C. After polymerization, the product is dissolved in acetone, precipitated in methanol, washed and dried to obtain a solid ultraviolet light cross-linked copolymer with a number-average molecular weight of 60,000 g / mol.

[0037] UV cros...

Embodiment 3

[0039] 20 parts of 4-(2-hydroxy-3-allyloxy-propoxy) benzophenone, 6 parts of methyl methacrylate, 10 parts of ethyl acrylate, 40 parts of butyl methacrylate (change to 40) 1, 11 parts of butyl acrylate, 8 parts of isooctyl acrylate, 5 parts of 2-hydroxyethyl methacrylate and 2 parts of acrylic acid as the unsaturated monomer composition. Among them, 4-(2-hydroxy-3-allyloxy-propoxy)benzophenone is a UV active monomer, and the others are monofunctional monomers.

[0040] In a reaction kettle with a stirrer, temperature control device, condensing device, dropping device and thermometer, with unsaturated monomer composition and 1 part of azobisisobutyronitrile as the main raw materials, carry out conventional bulk at 80 ° C. After polymerization, the product is dissolved in acetone, precipitated in methanol, washed and dried to obtain a solid ultraviolet light cross-linked copolymer with a number average molecular weight of 15000 g / mol.

[0041] UV light cross-linked copolymer so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com