Epoxy resin material used for toughening and reinforcing of hyperbranched polyether type epoxy resin and preparation method thereof

A technology of hyperbranched polyether and epoxy resin, applied in the field of organic polymers, can solve problems such as cumbersome steps, and achieve the effects of wide source, improved toughness and strength, and improved impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

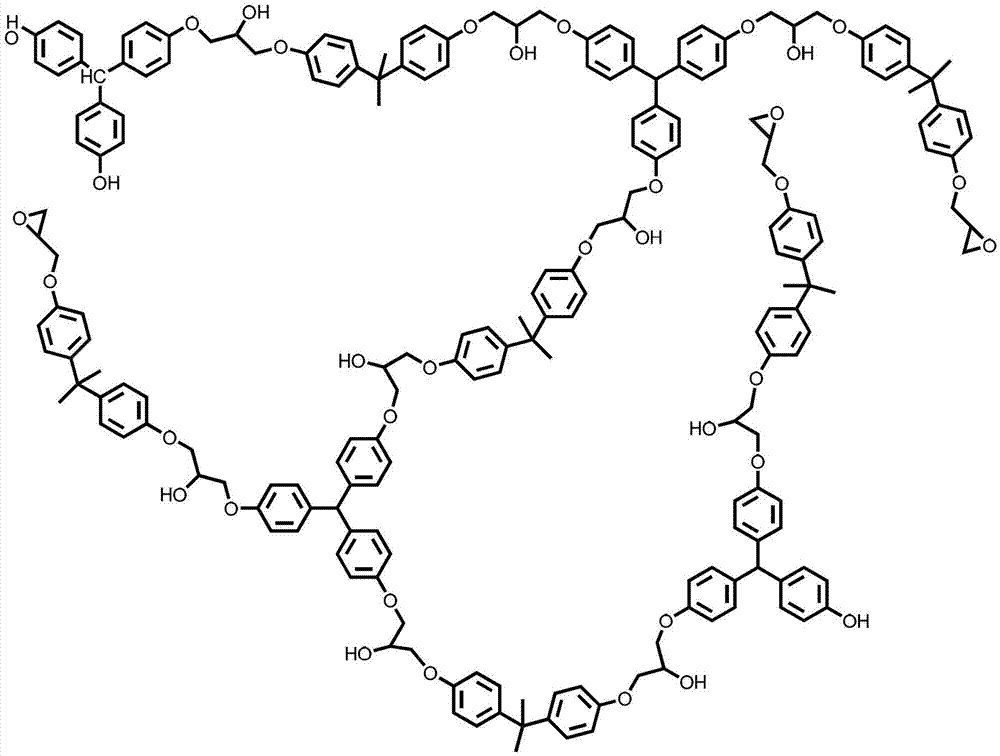

Method used

Image

Examples

Embodiment example 1

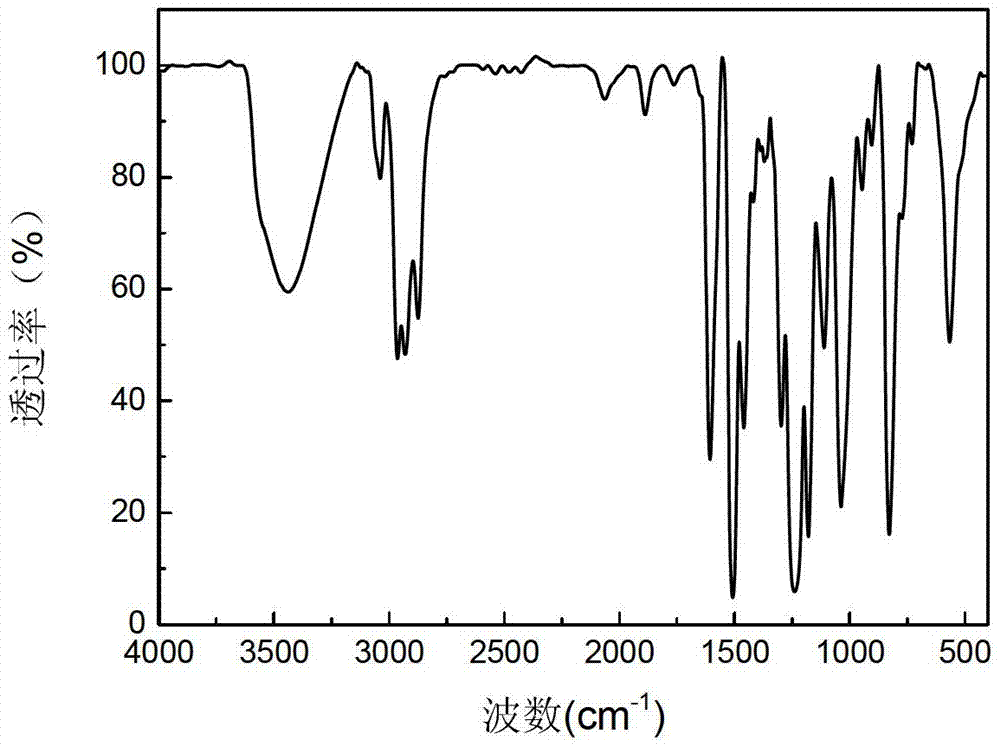

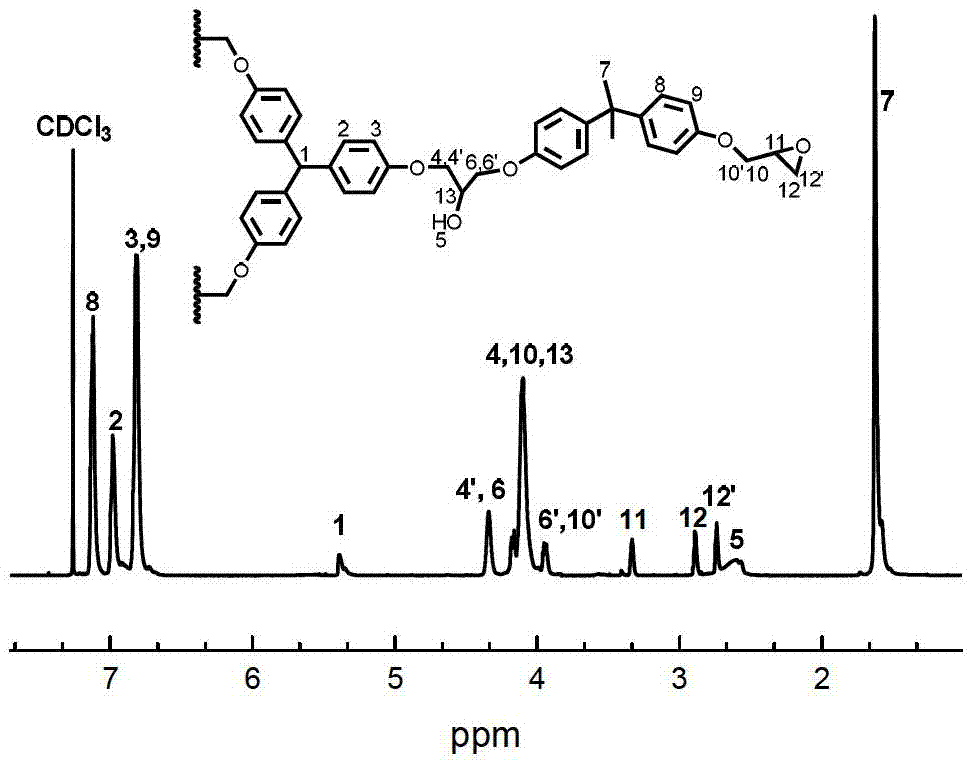

[0043] In a 1000ml four-neck flask equipped with mechanical stirring and a condenser, under nitrogen protection, add 230g E51, 80g trisphenolyl methane, dissolve in 150ml dioxane, add 10g tetrabutylammonium bromide, at reflux temperature Under reaction 72h. After the reaction, pour the reactant into a 2000ml beaker, slowly add methanol to obtain a white precipitate, pour out the supernatant, dissolve the polymer with 100ml tetrahydrofuran, then pour into ethanol / water (8:1), and wash repeatedly. 3 times. The white precipitate was dried to obtain 215g of hyperbranched polyether epoxy polymer with a weight of 7696 and a molecular weight distribution of 2.5. The infrared spectrum of the polymer is shown in figure 2 , 1 HNMR spectrum see image 3 .

Embodiment example 2

[0045] In a 1000ml four-necked flask equipped with mechanical stirring and a condenser, under nitrogen protection, add 230g E51, 80g trisphenolyl methane, dissolve in 150ml dioxane, add 15g tetrabutylammonium bromide, at reflux temperature Under reaction 72h. After the reaction, pour the reactant into a 2000ml beaker, slowly add methanol to obtain a white precipitate, pour out the supernatant, dissolve the polymer with 100ml tetrahydrofuran, and then pour into the methanol / ethanol mixture (3:7), so Wash repeatedly 3 times. The white precipitate was dried to obtain 220 g of a hyperbranched polyether type epoxy polymer with a weight of 14618 and a molecular weight distribution of 3.1.

Embodiment example 3

[0047] In 1000ml equipped with mechanical stirring, in the four-necked flask of condenser tube, under nitrogen protection, add 230g E51, 80g triphenolyl methane, be dissolved in 150ml ethylene glycol dimethyl ether, add 5g tetrabutylamine hydroxide, in Reaction at reflux temperature for 96h. After the reaction is over, pour the reactant into a 2000ml beaker, slowly add methanol to obtain a white precipitate, pour out the supernatant, dissolve the polymer with 100ml tetrahydrofuran, and then pour methanol / ethanol mixture (2:8), so Wash repeatedly 3 times. The white precipitate was dried to obtain 225g of a hyperbranched polyether type epoxy polymer with a weight of 20913 and a molecular weight distribution of 2.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com