Nitride fluorescent powder and preparation method thereof

A nitride phosphor, nitrogen technology, applied in the field of phosphors, can solve problems such as the inability to fully meet the needs of the application, and achieve the effects of improving luminous performance, simple process control, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

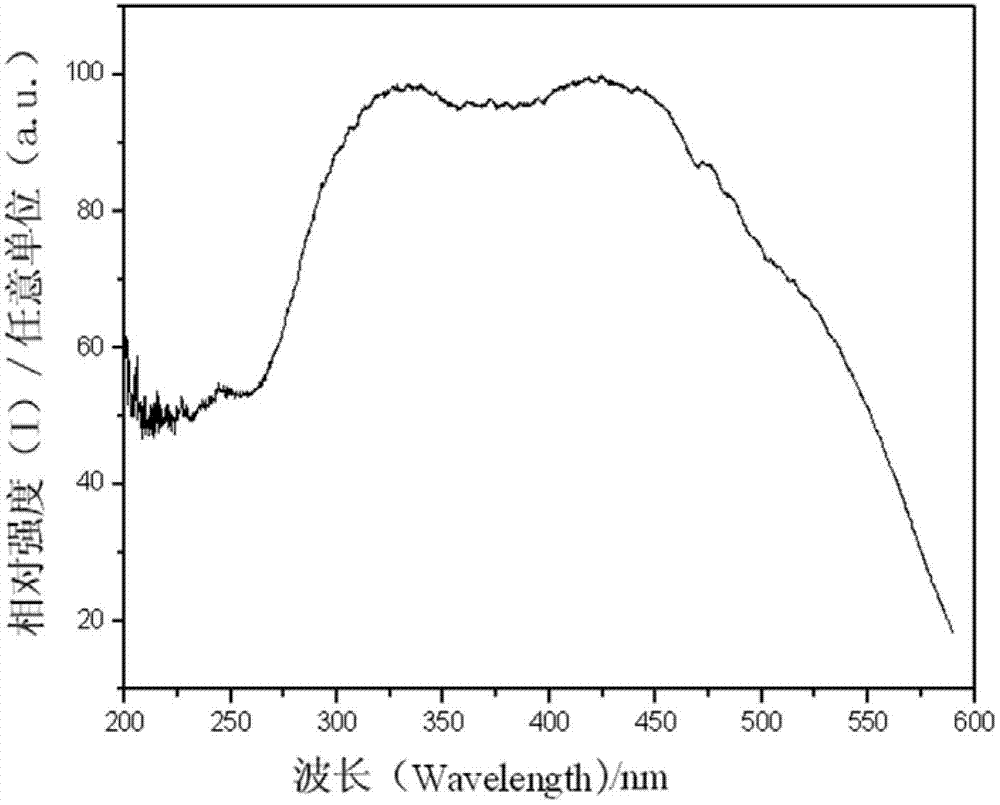

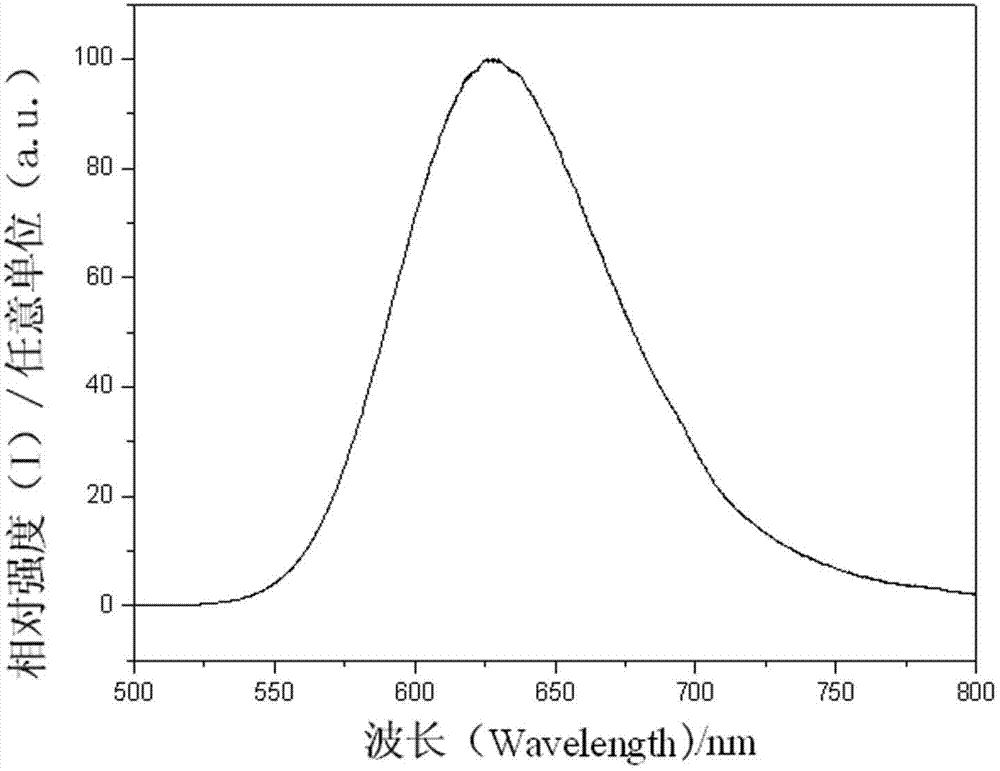

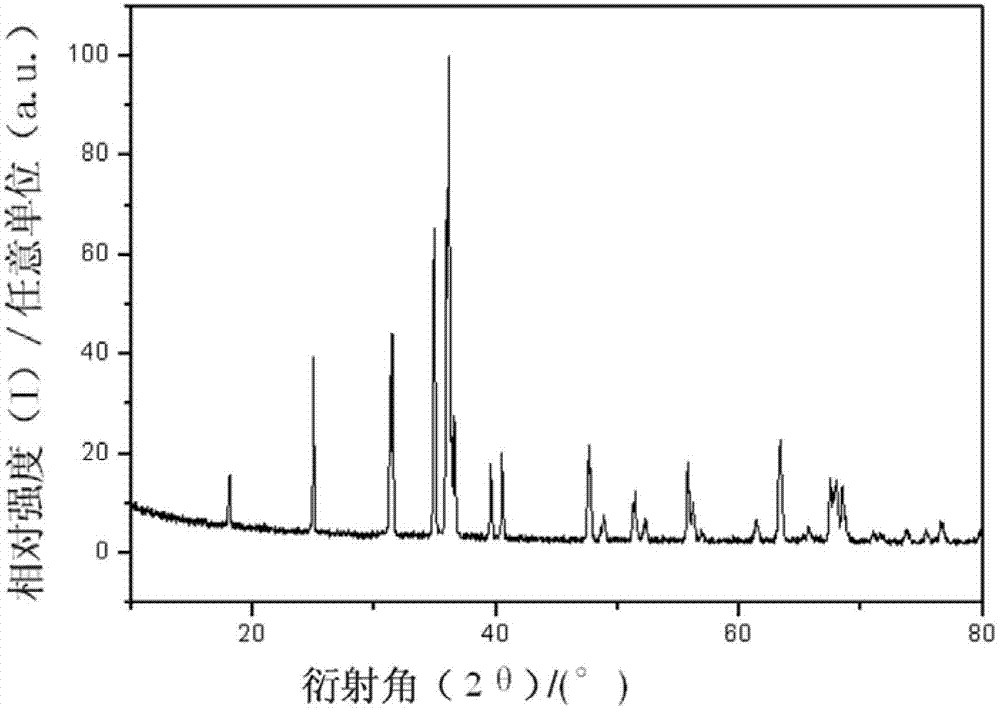

[0028] Weigh Ca 3 N 2 1.056g, Sr 3 N 2 8.732g, Si 3 N 4 5.001g, P 2 o 5 0.4g, AlN 4.614g, Eu 2 o 3 0.198g, the above raw materials are packed in the mixing tank in the glove box protected by argon, then mixed on the mixer for 3 hours, after mixing evenly, put into the molybdenum crucible, then move it into the tube furnace rapidly, then Under the protection of pure nitrogen atmosphere, the temperature is gradually raised to 1700°C, and the temperature is kept for 15 hours to prepare Ca 0.19 Sr 0.8 AlSi 0.95 P 0.05 N 2.926 : 0.01Eu nitride phosphor. Its excitation spectrum is shown in figure 1 , the emission spectrum see figure 2 , XRD pattern see image 3 , and its luminous intensity is shown in Table 1, which is higher than Comparative Examples 1 and 2.

Embodiment 2

[0030] Weigh Ca 3 N 2 1.016g, Sr 3 N 2 8.759g, Si 3 N 4 5.016g, P 2 o 5 0.401g, AlN 4.165g, BN 0.28g, Eu 2 o 3 0.199g, Gd 2 o 3 0.164g, the above raw materials are packed in the mixing tank in the glove box protected by argon, then mixed on the mixer for 3 hours, after mixing evenly, put into the molybdenum crucible, then move it into the tube furnace rapidly, then Under the protection of pure nitrogen, the temperature is gradually raised to 1700 ° C, and the temperature is kept for 15 hours to prepare Ca 0.182 Sr 0.8 Al 0.9 B 0.1 Si 0.95 P 0.05 N 2.922 : 0.01Eu, 0.008Gd nitride phosphor. The emission main peak and luminous intensity are shown in Table 1, and the luminous intensity is higher than that of Comparative Examples 1 and 2.

Embodiment 3

[0032] Weigh Ca 3 N 2 0.993g, Sr 3 N 2 8.662g, Si 3 N 4 4.96g, P 2 o 5 0.396g, AlN 4.576g, Eu 2 o 3 0.196g, Tm 2 o 3 0.215g, the above raw materials are packed in the mixing tank in the glove box protected by argon, then mixed on the mixer for 3 hours, after mixing evenly, put into the molybdenum crucible, then move it into the tube furnace rapidly, then Under the protection of pure nitrogen, the temperature is gradually raised to 1700 ° C, and the temperature is kept for 15 hours to prepare Ca 0.18 Sr 0.8 AlSi 0.95 P 0.05 N 2.92 : 0.01Eu, 0.01Tm nitride phosphor. The emission main peak and luminous intensity are shown in Table 1, and the luminous intensity is higher than that of Comparative Examples 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com