Esophagus repairing material

A repair material and technology for esophagus, applied in medical science, prosthesis, etc., can solve problems such as insufficient mechanical strength, plastic difficulty, growth factor damage, insufficient supporting force, etc., and achieve good clinical application prospects, good histocompatibility, and rigidity big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

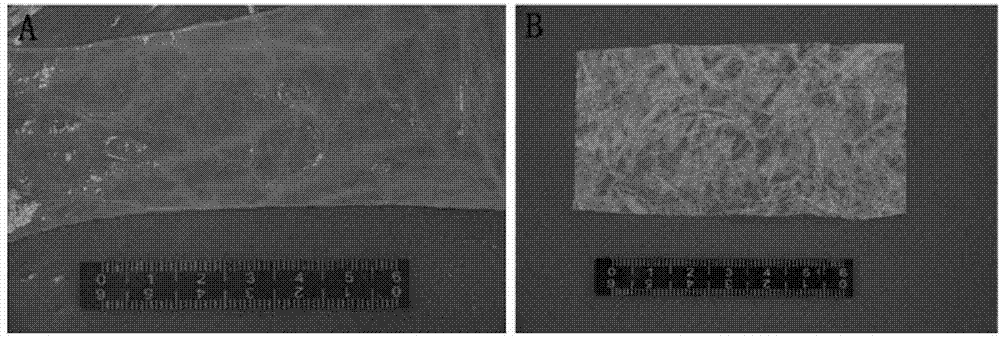

[0045] Embodiment 1 Preparation of esophageal repair material of the present invention

[0046] 1. Preparation of SIS

[0047] The SIS of the present invention can be prepared by the following method, and commercially available products can also be used.

[0048] (1) Cleaning and finishing: take the fresh pig small intestine half an hour after slaughter, wash away the contents of the small intestine with water, turn over the small intestine, add salt and rub it, rinse it repeatedly with water for 3 times, cut open the small intestine with a scalpel, and then cut it into 15 cm long of the intestinal segment.

[0049] (2) Isolate the SIS: scrape off the muscular layer and serosa layer with a tongue depressor, and store in normal saline at 4°C overnight.

[0050] (3) Degreasing: Rinse with deionized water and drain the water with gauze. Immerse in the mixture of chloroform-methanol, the ratio of chloroform: methanol is 1:1, put it in the fume hood for 4 hours, change the liqui...

Embodiment 2

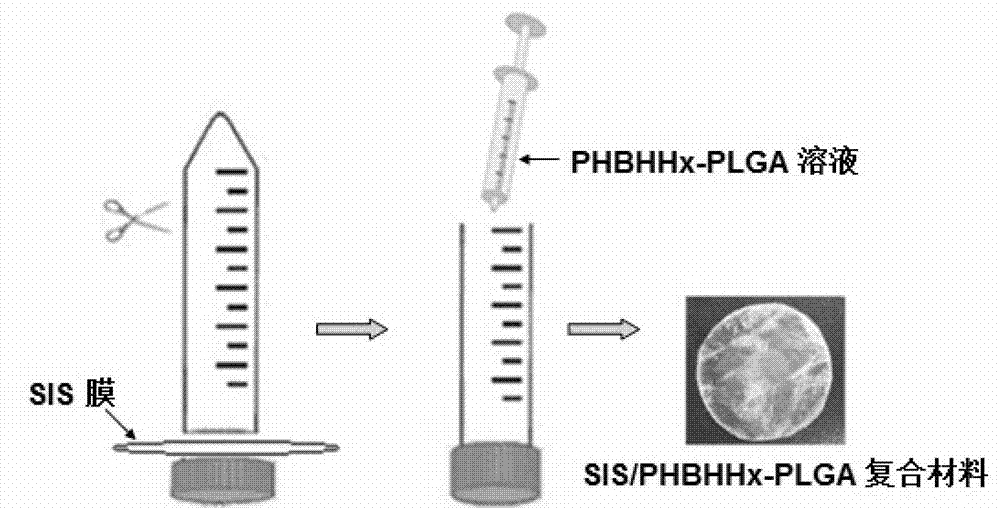

[0082] Example 2 Preparation and detection of long tubular SIS / PLGA-PHBHHx composite material

[0083] Take a 5cm stainless steel iron rod with a diameter of about 2mm, wet the SIS film prepared in Experimental Example 1 with water and wrap it around the outer edge of the iron rod for 2 laps, take 5ml of PHBHHx-PLGA mixed solution (5:5) and repeatedly cast it on the iron rod SIS For the outer layer of the film, the iron rod is continuously rotated during the casting process, and after it is solidified, it is freeze-dried. Gently take out the inner iron rod, and after the two ends are flattened, the tubular SIS / PLGA-PHBHHx composite material is obtained, such as Figure 7 a.

[0084] The bilayer structure of tubular composites after acridine orange (AO) staining was observed by confocal laser scanning microscopy, as Figure 7 As shown in B, the inner green ring is the double-layer SIS film, and the outer blue ring is the PHBHHx-PLGA composite.

[0085] The experimental resul...

experiment example 1

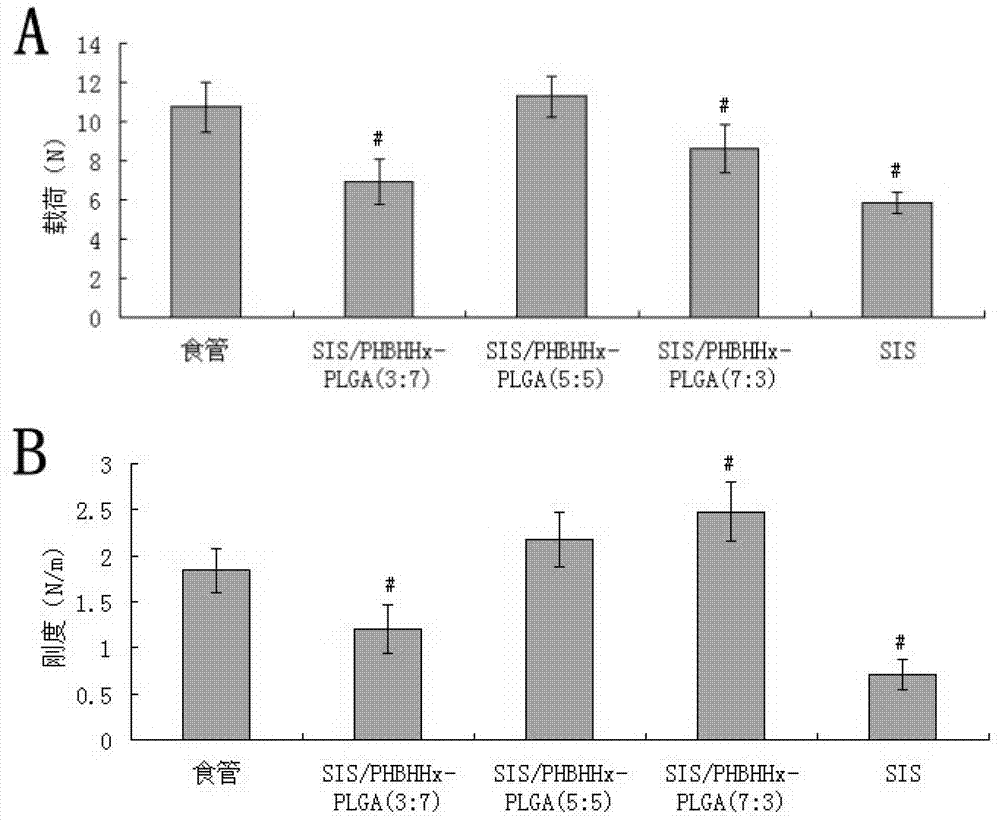

[0087] The detection of experimental example 1 SIS / PLGA-PHBHHx composite material of the present invention

[0088] Take the SIS / PLGA-PHBHHx (5:5) composite material prepared in Example 1 for the following tests:

[0089] (1) Determination of the release of VEGF and TGF-β growth factors in SIS / PLGA-PHBHHx composites by ELISA

[0090] Take 0.1g of the SIS film prepared in Example 1 and 3 groups of SIS / PHBHHx-PLGA composite materials prepared from 0.1g of the SIS film, soak in 3ml of PBS at 37°C under sterile conditions, and take out 1ml of the material extract every 48 hours. And add 1ml of fresh sterile PBS, continuous sampling for 30 days. The content of VEGF and TGF-β in the material extract was measured by ELISA method.

[0091] The result is as Figure 8 As shown, the SIS / PHBHHx-PLGA composite continuously releases VEGF and TGF-β growth factors. At 30 days, the cumulative release of VEGF reached 657ng / ml, and the cumulative release of SIS film was 811ng / ml; the cumulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com