Flow and device for aquaculture sewage combination purifying treatment

An aquaculture, purification and treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as large usage, secondary environmental pollution, and unfavorable economic utilization. , to achieve the effect of good adaptability and efficiency, easy operation and saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

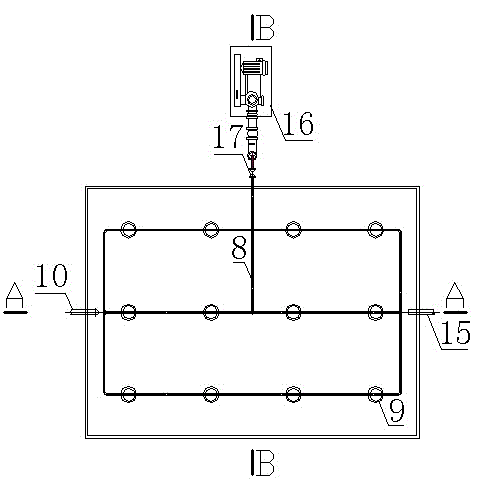

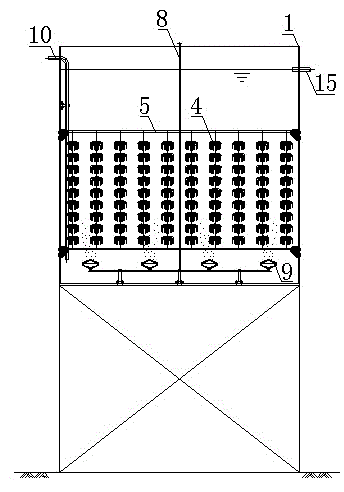

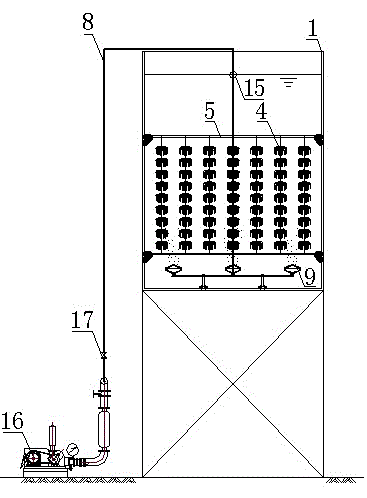

[0020] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, the present invention's treatment process is to carry out pulse aeration and oxygenation while carrying out biological contact oxidation to aquaculture wastewater, and then carry out drip filtration process again; Pulse aeration and oxygenation adopt time relay and Electromagnetic valve control, oxygenation 5min, stop oxygenation 10min.

[0021] Such as figure 1 As shown, the device for completing the treatment process of the present invention includes a biological contact oxidation tank 1, a dosing tank 2 and a trickling filter tank 3; the biological contact oxidation tank 1 is connected to the water inlet pipe 10, and the biological contact oxidation tank 1 and the dosing tank 2 pass through the water pipe 15 Connection, the dosing tank 2 is connected to the trickling filter tank 3 through a siphon 11, and the trickling filter tank 3 is connected to the outlet pipe 12 nea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com