Photosensitive solder resist composite, application thereof and printed circuit board (PCB) containing same

A technology of photosensitive solder resist and composition, which is applied in the secondary treatment of printed circuits, photosensitive materials used in optomechanical equipment, optics, etc., can solve the problems of poor heat resistance, achieve good hardness and light aging resistance, and good The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

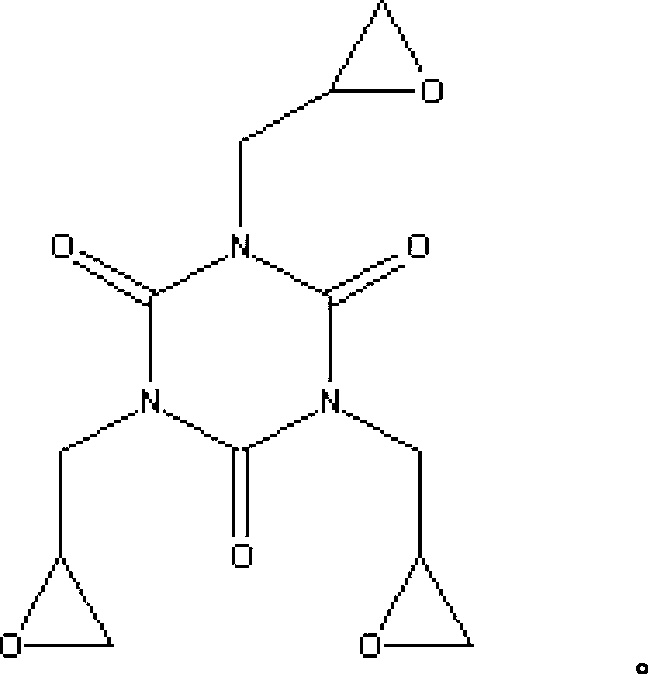

[0074] Synthesis example 1 (preparation of alkali-soluble photosensitive resin A1 obtained by TGIC)

[0075] In a 1L reactor equipped with a thermometer, stirrer, reflux condenser and dropping funnel, add 150 grams of TGIC (epoxy equivalent 102, purchased from Changzhou Niutang Chemical Factory Co., Ltd.), add 300 grams of TGIC under stirring Diethylene glycol monoethyl ether acetate is used as a solvent, 0.5 g of hydroquinone as a polymerization inhibitor and 2 g of triphenylphosphine as a reaction catalyst. The mixture was heated to 95°C, and after TGIC was completely dissolved, 104 g of acrylic acid was slowly added dropwise, and then reacted at 95°C-100°C for 15 hours until the detected acid value of the mixture was less than 5 mg KOH / g. After the temperature in the reactor dropped to 85°C-90°C, 100 grams of tetrahydrophthalic anhydride was added and reacted for 6 hours to obtain light yellow transparent liquid resin A1 with an acid value of 58 mgKOH / g and a solid content ...

Embodiment 2

[0076] Synthesis Example 2 (preparation of epoxy resin of the present invention)

[0077] Add 150 grams of diethylene glycol monoethyl ether acetate as a solvent in a 1L reactor equipped with a thermometer, stirrer, reflux condenser and dropping funnel, and heat to 80-82 ° C; under stirring and nitrogen protection Next, add 10 grams of azobisisobutyronitrile peroxide, keep the temperature at 80-82 ° C, drop the mixture of glycidyl methacrylate and methyl methacrylate (140:60 by weight) within two hours 200 grams, followed by insulation and stirring for two hours, then the temperature was raised to 120°C for one hour. The temperature was lowered to obtain a polymer solution (M-1) with a weight average molecular weight of 20,000, a solid epoxy equivalent of 200, and a solid content of 58.3%.

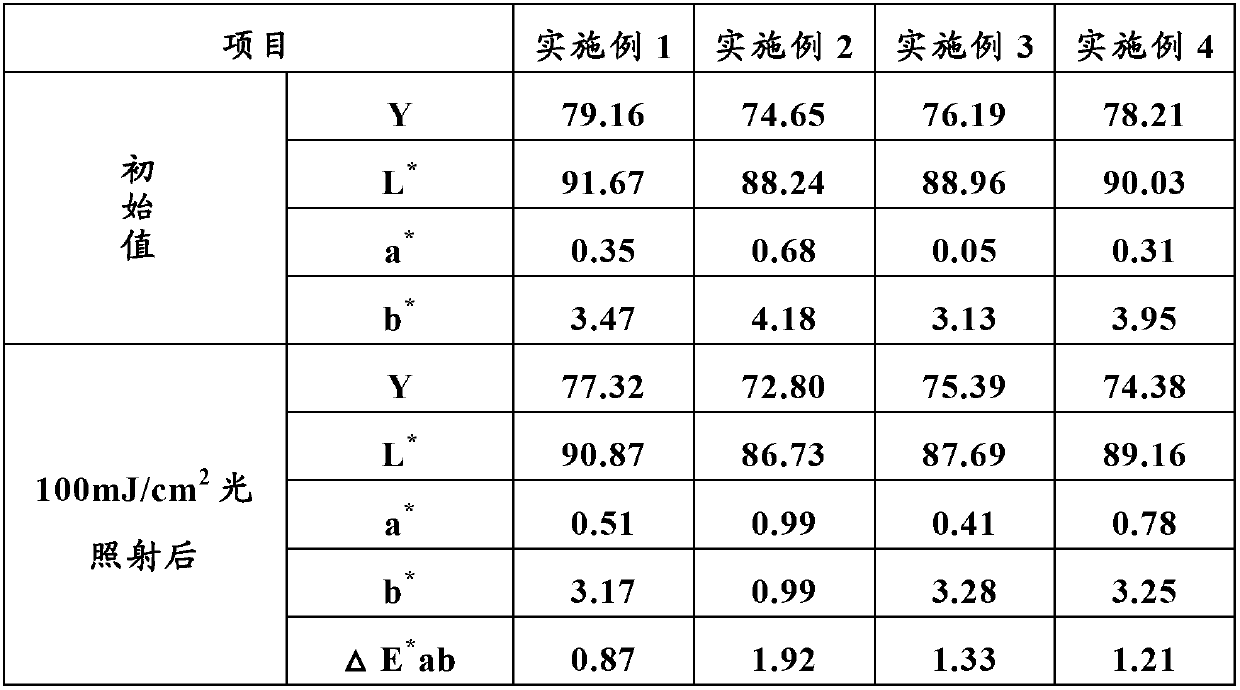

Embodiment 1-8 and comparative example 1-4

[0081] Mix the resin A1 and resin A2 obtained in the above synthesis example according to the formulations in Table 1, Table 1' and Table 2 respectively, first use a disperser (U400\80-220 high-speed disperser) to disperse at high speed for 15 minutes, and then use A three-roll mill (S-65 three-roll mill) was ground three times to obtain photosensitive solder resist compositions. The numbers in the table represent parts by weight.

[0082] Table 1

[0083] Material

Example 1

Example 2

Example 3

Example 4

Resin A1

45

45

45

45

M-1

15

15

15

15

Irgacure TPO

3

3

-

3

Irgacure 819

-

-

3

3

Irgacure 907

-

-

-

-

ITX

-

3

-

-

36

36

36

36

DPHA

4

4

4

4

Diethylene glycol ethyl ether acetate

5

5

5

5

1

1

1

1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com