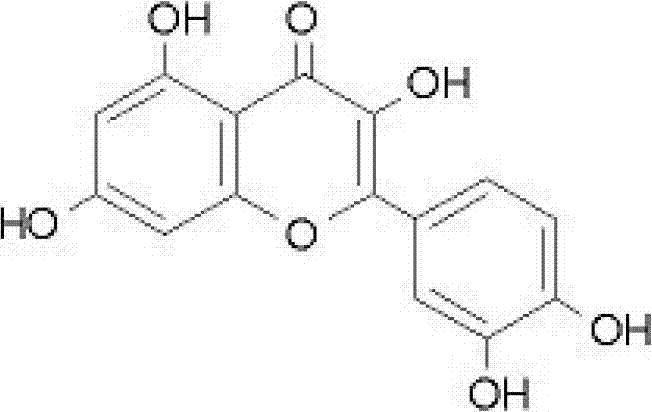

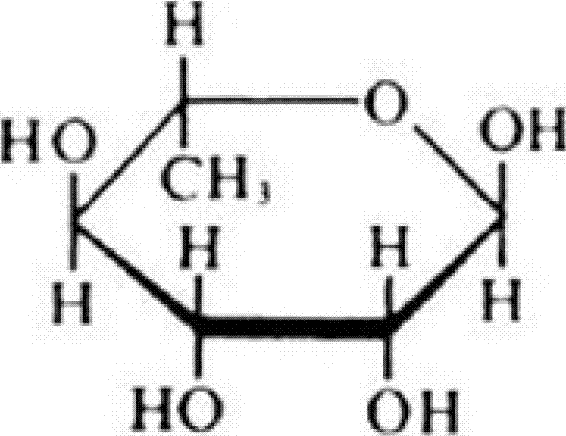

Method for preparing quercetin and rhamnose by using flos sophora

A technology of rhamnose and quercetin, which is applied in the field of plant extraction, can solve problems such as waste, difficult operation, large energy consumption, etc., and achieve the effects of saving resources, overcoming pollution, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical scheme of the present invention will be further described below through specific embodiments:

[0016] (1) Take 600Kg of Sophora japonica, crush it to 10 mesh, add 80Kg of drinking water and mix it wet, put it in the extraction tank, steam it with steam for 1.5 hours, take it out and dry it in the air for 5 hours, then divide it into 6 percolation tanks, use Drinking water at 40°C removes colloids, and about 4 tons of water is used.

[0017] (2) Weigh 82Kg of borax, 7.9Kg of sodium sulfite, 800g of sodium bisulfite and 800g of ethylenediaminetetraacetic acid, dissolve them in hot water, add them to 15 tons of saturated clarified lime water, and mix well. Heat the lime water to 40°C, start to leak, the flow rate is 60L / min, until the pH of the seepage is 12, stop the seepage, adjust the pH of the seepage to 4 with hydrochloric acid, carry out crystallization, filter after 6 hours, Get 250Kg of rutin filter cake (after testing, the water content in the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com