Inorganic nonmetallic mineral composite material loaded with titanium dioxide layer, preparation method and application thereof

An inorganic non-metallic and composite material technology, applied in the field of inorganic non-metallic mineral composite materials, can solve the problems of high refractive index, high hiding power performance, insufficient loading firmness, and high equipment requirements that limit titanium dioxide, so as to achieve photocatalytic activity , low cost, and the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] Add 400 grams of 1250 mesh sericite to a mixed solution of 1100 grams of water, 70 grams of sulfuric acid, 1.6 grams of sodium hexametaphosphate and 0.4 grams of polyacrylamide, and stir at 80-90°C to form a uniformly dispersed suspension; weigh; Take 50 grams of titanium tetrachloride, add 110 grams of an aqueous solution containing 3 grams of polyethylene glycol 1200, 1 gram of polyvinyl alcohol (PVA), and 0.5 grams of polyimide dispersant into the titanium tetrachloride dropwise to prepare stable tetrachloride. Titanium chloride hydrolyzate: Add the titanium tetrachloride hydrolysate dropwise to the sericite-containing suspension. After 4 hours of reaction, filter and wash until the pH of the filtrate is close to 4 to obtain a composite filter cake, which is functional after drying Composite material 1.

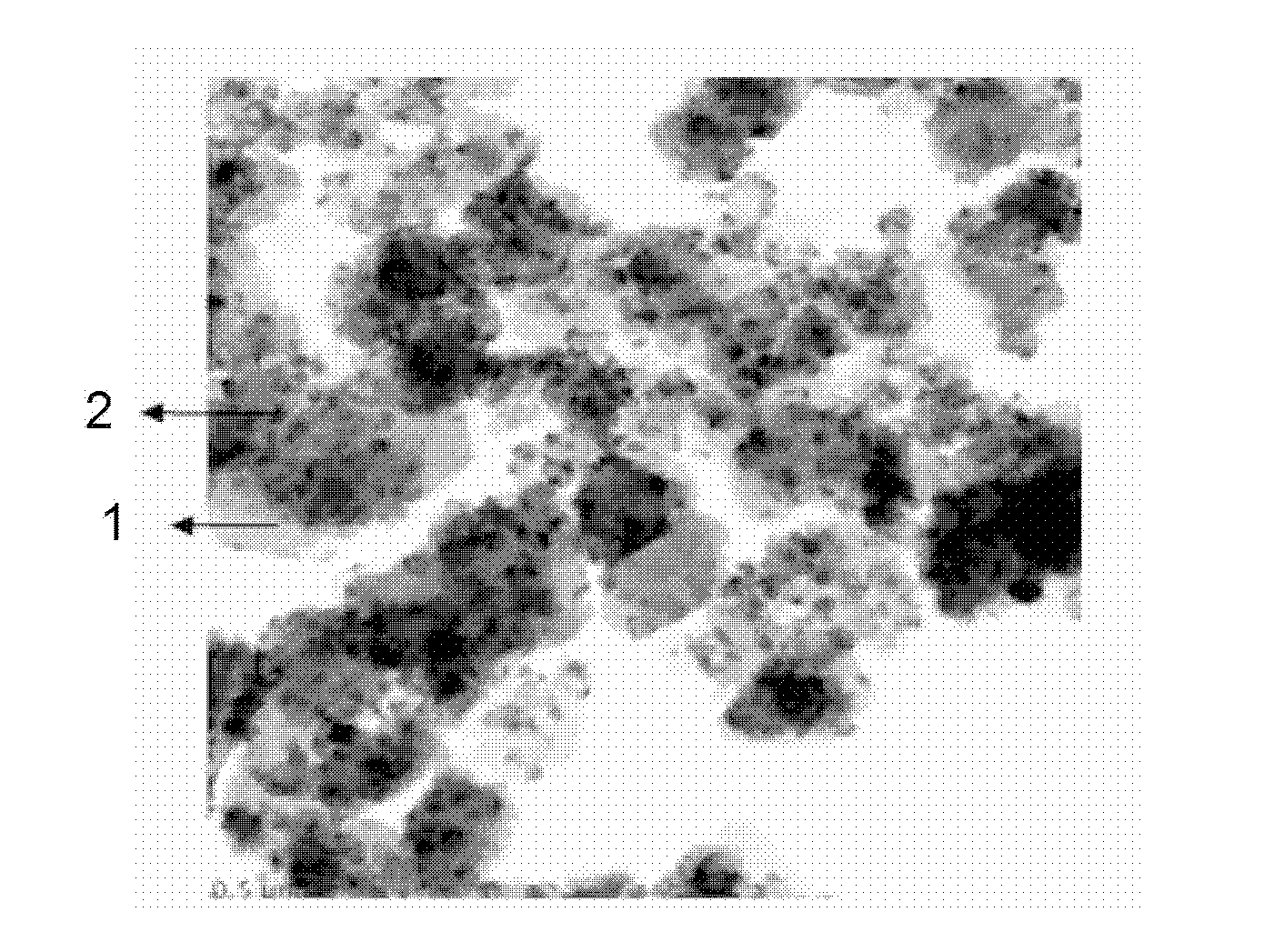

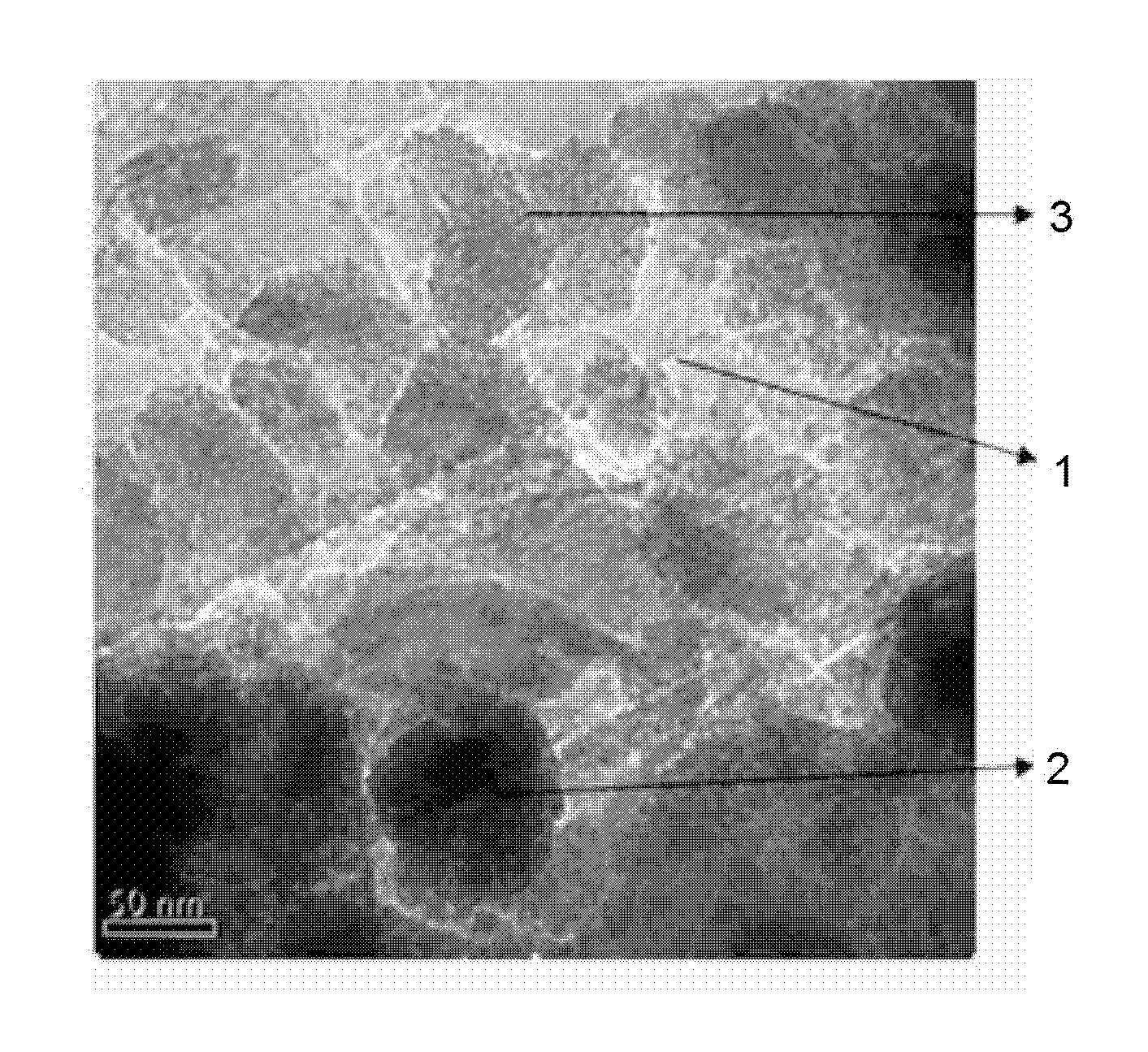

[0093] The following observations and tests were performed on the obtained composite product.

[0094] Load detection

[0095] According to the GB\T 1706-2006 standard,...

Embodiment 2

[0101] Add 500 grams of 800 mesh kaolin to a mixed solution of 2000 grams of water, 300 grams of hydrochloric acid, 50 grams of sulfuric acid, 2 grams of sodium hexametaphosphate, and 1 gram of polyether L61 (Guangzhou Chengfeida Trading Co., Ltd.). Stir at 80-90℃ to form a uniformly dispersed suspension; weigh 240 grams of titanium tetrachloride, which will contain 6 grams of polycarboxylate TH-361 (Shandong Taihe Water Treatment Co., Ltd.), 3 grams of polyethylene glycol 1200, 1 1900 grams of polyvinyl alcohol (PVA) aqueous solution was added dropwise to titanium tetrachloride to prepare a stable titanium tetrachloride hydrolysate; the titanium tetrachloride hydrolysate was added dropwise to the suspension containing kaolin, and after 6 hours of reaction, filtered Wash with water until the pH of the filtrate reaches 5 to obtain a composite filter cake, which is dried to obtain functional composite material 2.

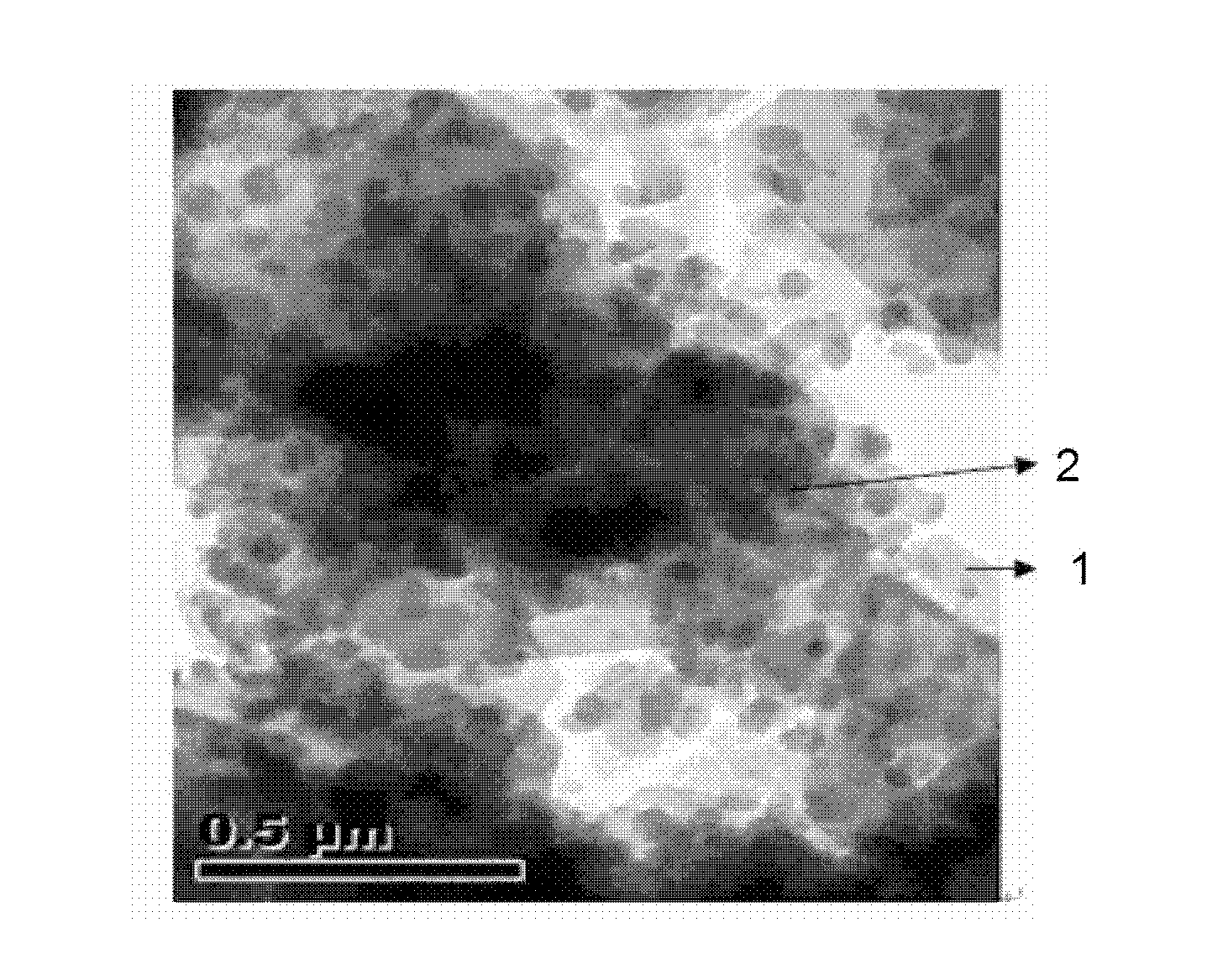

[0102] The following observations and tests were performed on the o...

Embodiment 3

[0108] Add 600 grams of 800 mesh sericite to 1100 grams of water, 40 grams of hydrochloric acid, 10 grams of sulfuric acid, 6 grams of sodium hexametaphosphate, and 2 grams of polycarboxylate GY-D06 (Sinchem Research Institute of Chemical Technology). In the solution, stir at 85-95℃ to form a uniformly dispersed suspension; weigh 200 g of titanium tetrachloride, which will contain 1 g of polyethylene glycol 1200, 0.4 g of polyvinyl alcohol (PVA), and 0.6 g of polyethylene glycol 600 grams of lauric acid PEG200ML (Jiangsu Haian Petrochemical Plant) aqueous solution was dropped into titanium tetrachloride to prepare a stable titanium tetrachloride hydrolysis solution; the titanium tetrachloride hydrolysis solution was dropped into the sericite-containing suspension, After reacting for 4 hours, filter and wash the filtrate until the pH of the filtrate is 7, to obtain a composite filter cake, and then obtain functional composite 3 after drying.

[0109] The following observations and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com