Preparation method of polyamino acid segmented copolymer and polyamino acid segmented copolymer hydrogel

A technology of block copolymer and polyamino acid, which is applied in the directions of non-active ingredient medical preparations, pharmaceutical formulations, aerosol delivery, etc., can solve the problem of ineffective enhancement of cancer cell endocytosis, and achieve good biocompatibility Sexuality and biodegradability, enhanced endocytosis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The embodiment of the present invention discloses a preparation method of a polyamino acid block copolymer, comprising the following steps:

[0035] reacting the compound represented by formula (I), L-cystine-N-endocarboxylic anhydride and amino acid-N-endocarboxylic anhydride in an organic solvent to obtain a polyamino acid block copolymer;

[0036]

[0037] Wherein R is hydrogen or methyl, preferably methyl;

[0038] The number average molecular weight of the compound represented by formula (I) is 500-30000.

[0039] The present invention uses the compound represented by formula (I), L-cystine-N-internal carboxylic acid anhydride and amino acid-N-internal carboxylic anhydride as raw materials to prepare the polyamino acid block copolymer. Under the initiation of the compound represented by formula (I), L-cystine-N-endocarboxylic anhydride and amino acid-N-endocarboxylic anhydride undergo ring-opening polymerization, wherein L-cystine-N-endocarboxylic anhydride Th...

Embodiment 1

[0061] Weigh 30g of N-(2-hydroxyethyl)phthalimide and 300ml of toluene to remove water azeotropically, then slowly add 0.285g of p-toluenesulfonic acid and 15.3ml of 2-methanol Oxypropylene. React in an ice bath for 1h. Then azeotrope with toluene to remove water for 3h, after cooling to room temperature, add 36ml triethylamine to terminate the reaction, and add 9ml acetic anhydride to neutralize unreacted N-(2-hydroxyethyl)phthalimide. The resulting product was recrystallized three times with 50ml of ethyl acetate, then refluxed for 12h in 6M sodium hydroxide solution, and extracted three times with 50ml of chloroform and isopropanol mixed solution with a volume ratio of 1:1 after cooling to room temperature. The phase was dried overnight with anhydrous magnesium sulfate, and the solvent was removed by a rotary evaporator to obtain an acid-sensitive diethylamino ketal, that is, a compound represented by formula (II), with a yield of 68.2%.

Embodiment 2~6

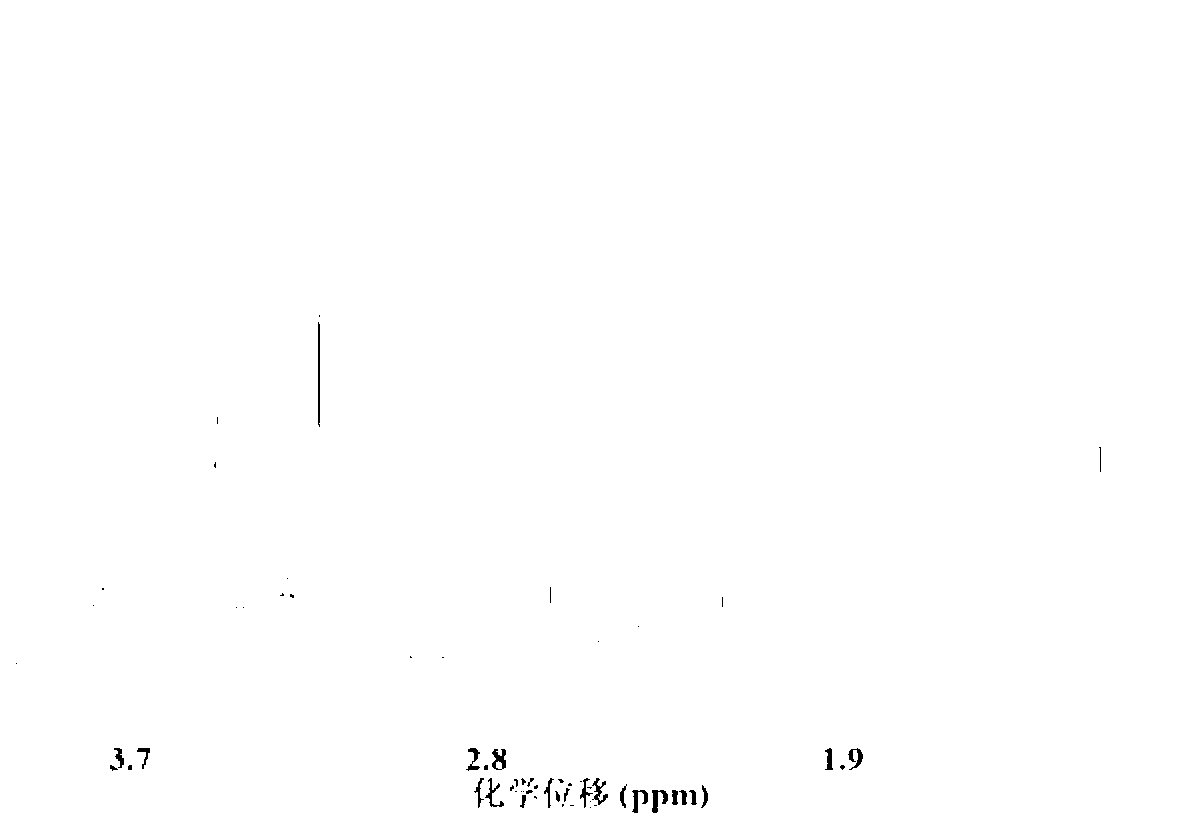

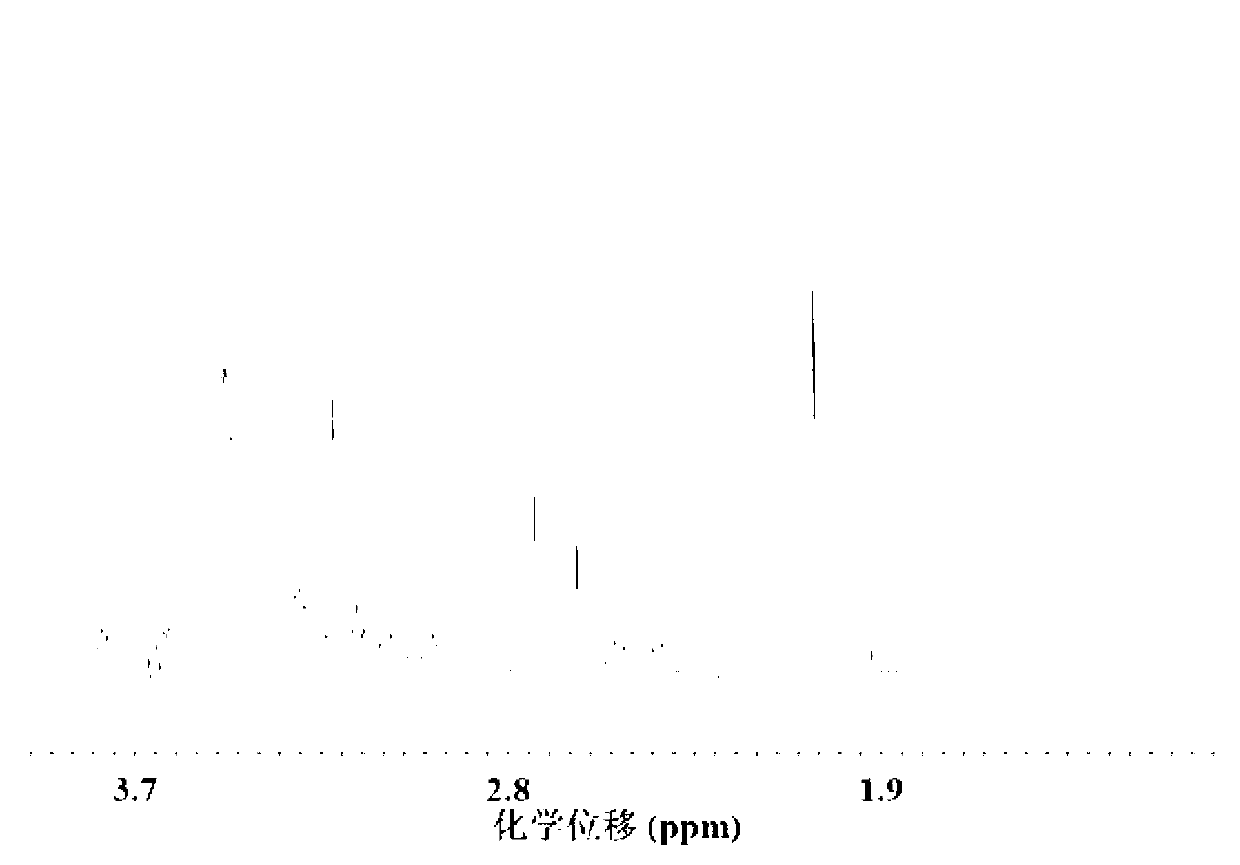

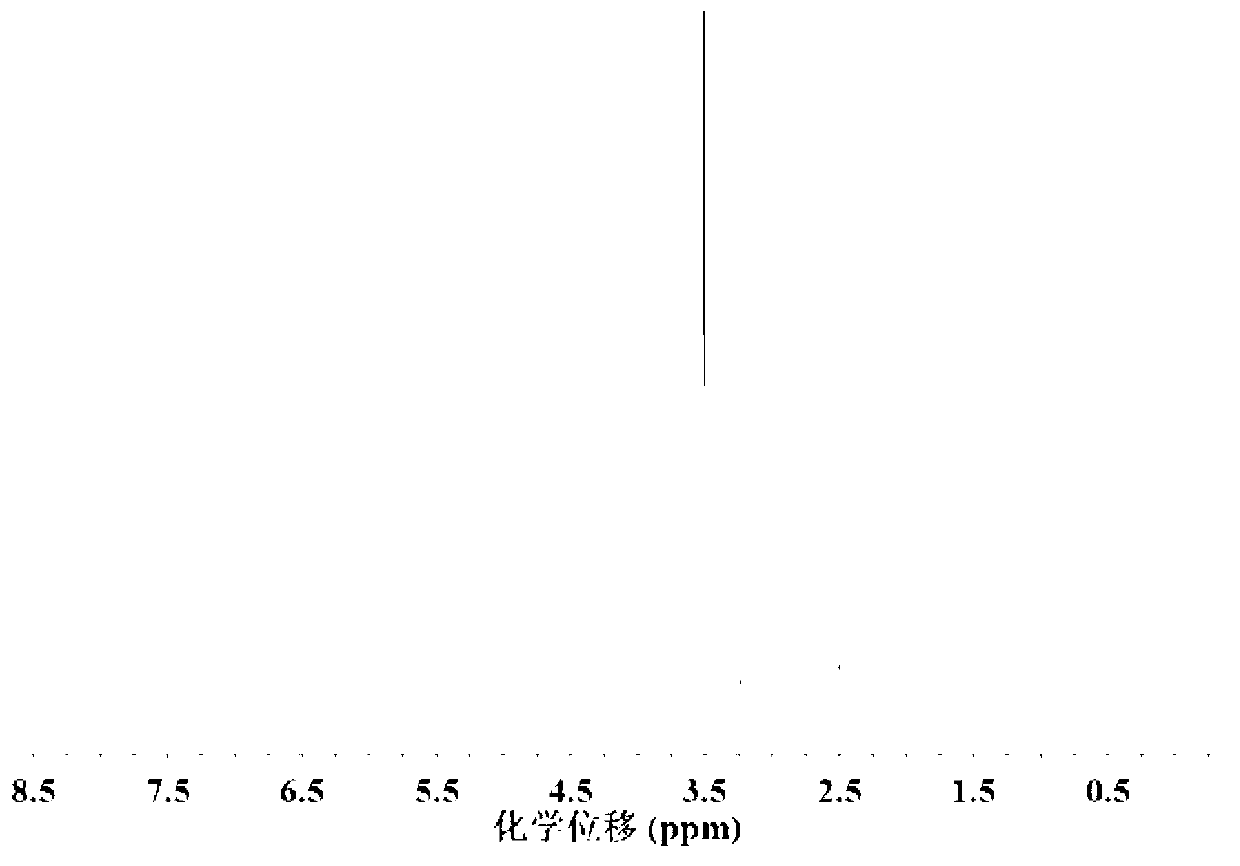

[0063] Weigh 20g of polyethylene glycol monomethyl ether with number average molecular weight of 1000 (0.02mol), 2000 (0.01mol), 5000 (0.004mol), 10000 (0.002mol) and 20000 (0.001mol) respectively, put into 5 In a dry reaction flask with a branch, add 100mL pyridine respectively, then add 30.02g (0.3mol), 15.01g (0.15mol), 6.01g (0.06mol), 3.02g (0.03mol) and 1.50g ( 0.0015mol) succinic anhydride, reacted 72h at 25 DEG C. After the reaction was completed, it was neutralized with 100ml of saturated sodium bicarbonate solution, washed three times with 50ml of ethyl acetate, extracted three times with 50ml of chloroform, dried, concentrated, and settled to finally obtain the compound shown in formula (III). The compound represented by the formula (III) was analyzed by nuclear magnetic resonance, and its number average molecular weight was calculated. See Table 1 for the results.

[0064] The number-average molecular weight and the productive rate of the compound shown in the for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com