Method for extracting protein in biological sludge

A technology of biological sludge and extraction method, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of black and sticky extraction liquid, excessive heavy metal ions, and heavy metal dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

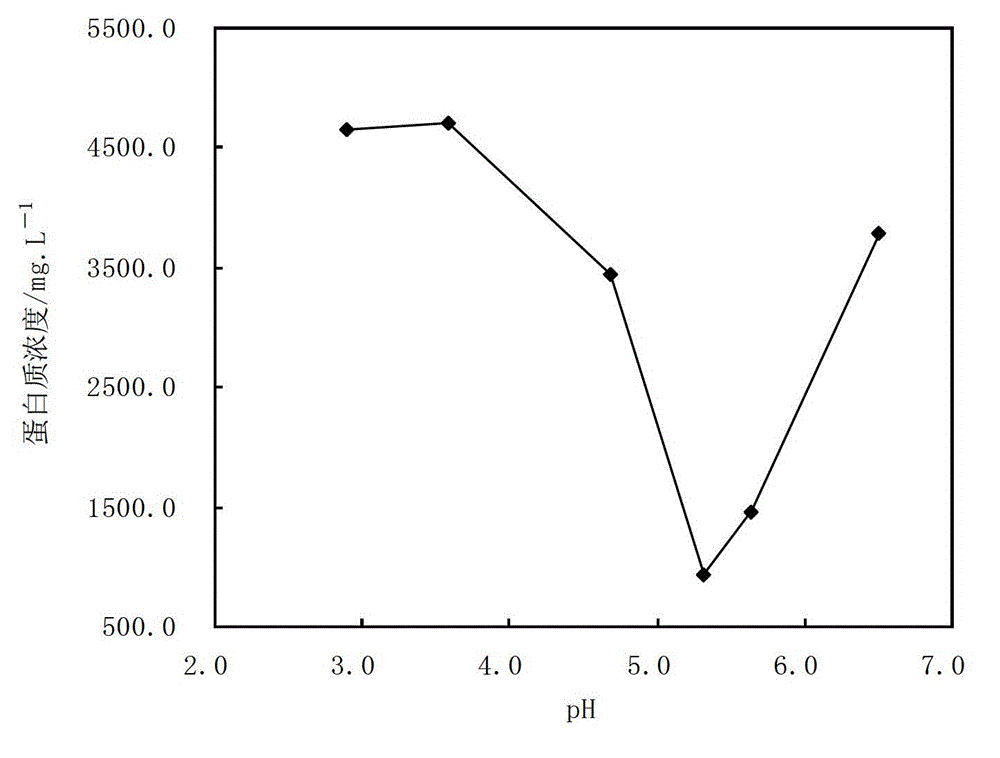

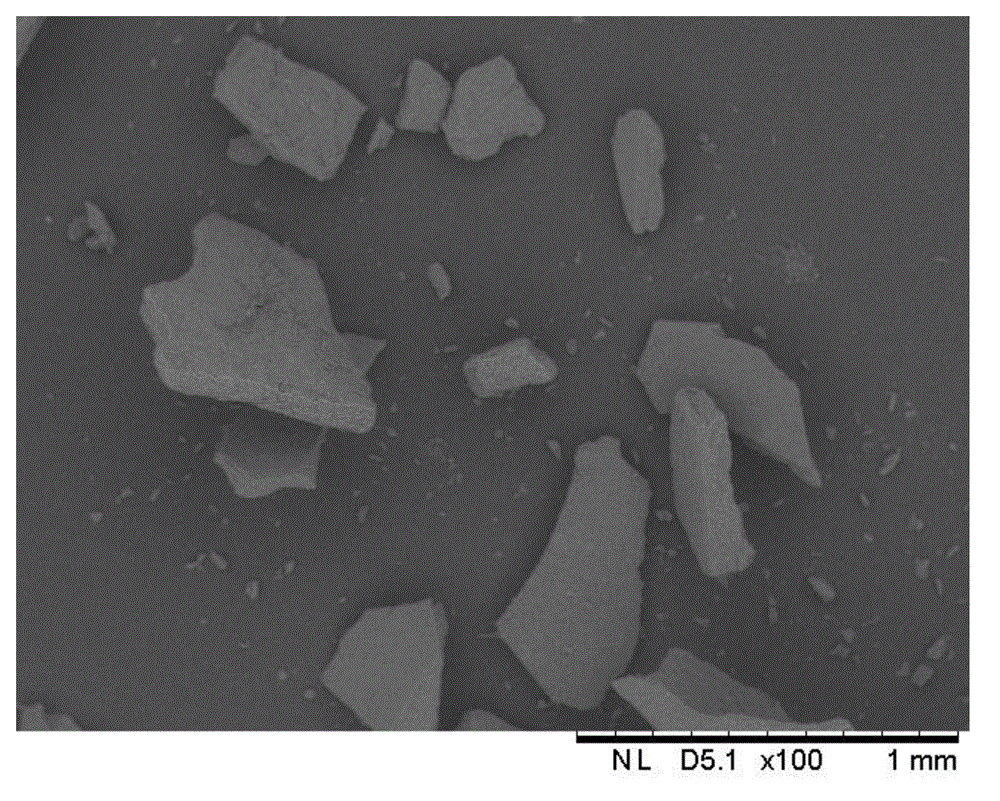

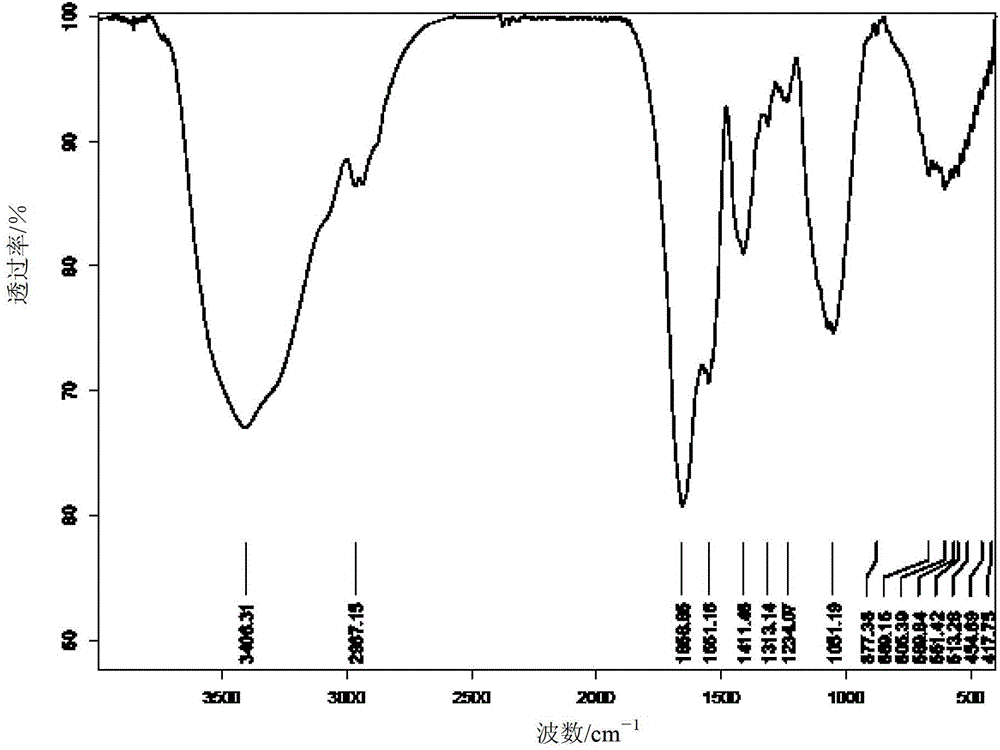

[0027] Take 500g of dewatered sludge from a sewage plant (with 80% moisture content), add 1750g of distilled water and 250g of concentrated hydrochloric acid, then stir at room temperature for 30 minutes, and perform centrifugal filtration to filter the filtrate to a moisture content of 92%, and then put the mud Put it into the container and put it into the high-temperature digestion device. Heat for 2h at 120°C. After cooling, perform centrifugal filtration to obtain about 450ml of filtrate. Take out 60ml of filtrate (the rest of the filtrate is stored in the refrigerator). Put it into a 50ml small beaker, adjust a series of pH with sodium hydroxide solution, respectively, to be 3.0, 4.2, 5.2, 5.6, 6.0 and 7.0, put it at room temperature for 12 hours, then perform high-speed centrifugation, save the supernatant, and determine the corresponding The pH of the supernatant was 2.9, 3.6, 4.7, 5.3, 5.6, and 6.5, and then the protein content in the supernatant was measured by the Feli...

Embodiment 2

[0029] Same as Example 1, except that the heating time is 5h and 8h, and there is no need to determine the protein isoelectric point. The obtained filtrate is directly subjected to protein precipitation at the isoelectric point determined in Example 1, and then washed with 95% ethanol , And dried, the solid materials obtained were 14.43g and 16.76g, respectively. Its protein content is 102.1% and 99.8% respectively. Corresponding heavy metals chromium, cadmium, mercury and arsenic were not detected, and the mass content of lead (calculated as PbO) was 0.02% and 0.03% respectively, which met the quality standard requirements for protein feed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com