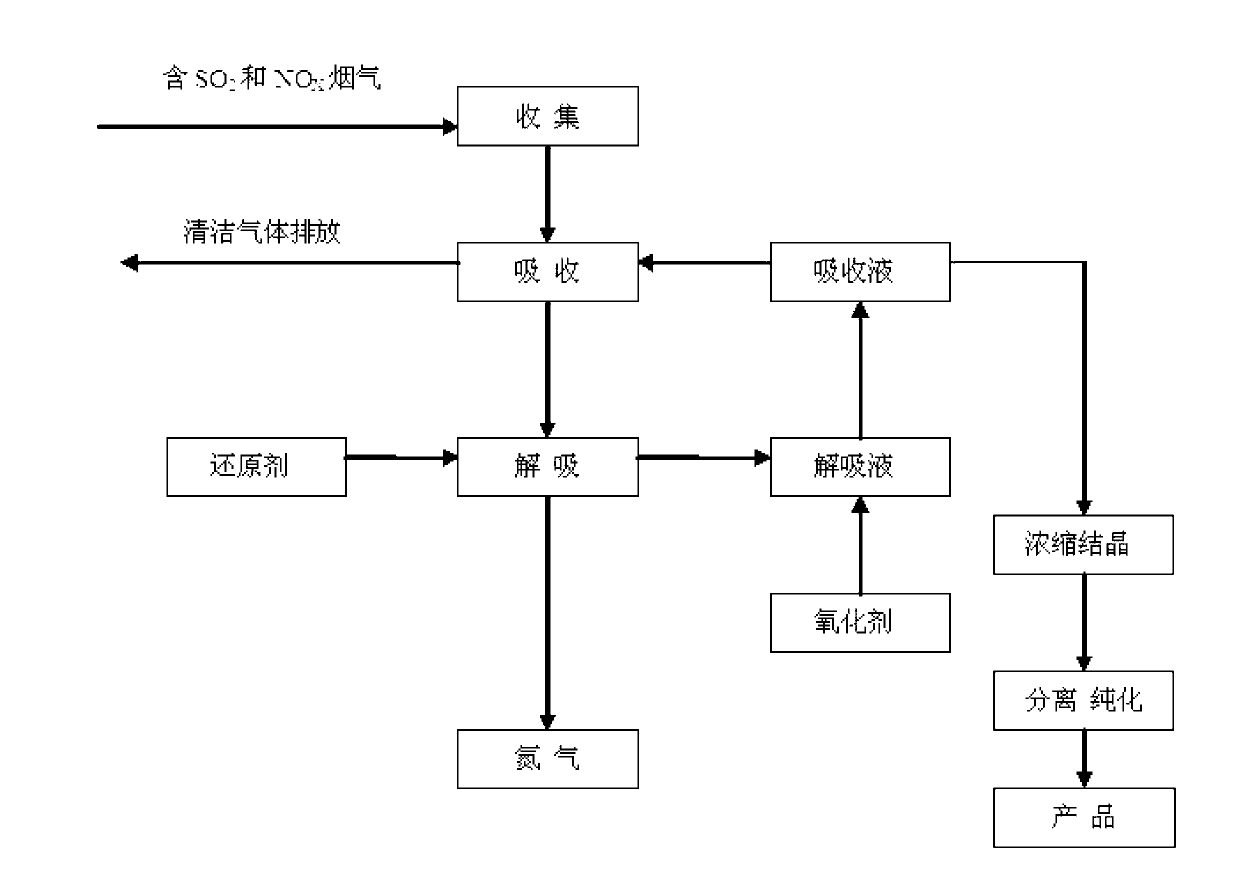

Flue gas wet reduction integrated desulfurization, denitrification, harmless treatment and resource utilization method

A desulfurization, denitrification, and harmless treatment technology, which is applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of high energy consumption of devices, high cost of organic solvents, catalyst stabilization, regeneration and reduction, and collection of by-products, etc. problems, to achieve the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 1 L of ferric chloride solution with a hydrogen ion concentration of 1 mol / L and a ferric iron concentration of 1.66 mol / L, and feed sulfur dioxide and nitrogen monoxide gas simultaneously at 30°C under one atmospheric pressure, the amount of which is 0.84 mol respectively , 1.66mol, the reaction time is 0-3h, stop until the absorption liquid turns dark brown, after standing for 1 hour, add 110g sodium sulfite solid and 5g activated carbon catalyst to the absorption liquid, stir well, the released gas is detected by gas detector, mainly The composition is nitrogen, no nitrogen oxides detected

[0026] A proper amount of oxygen is passed into the absorption solution after the above reduction treatment, and the divalent iron in the solution is converted into ferric iron. The resulting solution was concentrated and recrystallized to obtain 226 g of ferric sulfate product containing crystal water, 51 g of ferric chloride containing crystal water and a small amount of s...

Embodiment 2

[0028] Take 1 L of a mixed solution of ferric chloride and ferrous chloride with a hydrogen ion concentration of 0.6 mol / L, a ferric iron concentration of 1.66 mol / L, and a ferrous iron solution concentration of 0.54 mol / L. Simultaneously feed sulfur dioxide and nitrogen monoxide gas under atmospheric pressure, the feeding amount is 0.84mol, 2.2mol respectively, the reaction time is 0-3h, stop until the absorption solution turns dark brown, after standing for 1h, add 127g sodium sulfite to the absorption solution The solid and 5g of activated carbon catalyst were fully stirred, and the released gas was detected by a gas detector. The main component was nitrogen, and no nitrogen oxides were detected.

[0029] A proper amount of oxygen is passed into the absorption solution after the above reduction treatment, and the divalent iron in the solution is converted into ferric iron. The resulting solution was concentrated and recrystallized to obtain 259 g of ferric sulfate product c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com