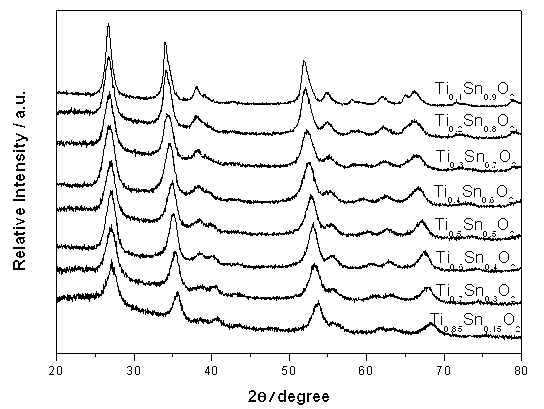

Preparation method of titanium dioxide-tin dioxide nano-sosoloid material

A tin dioxide, titanium dioxide technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, tin oxide, etc., to achieve the effect of improving photocatalytic performance and gas sensing performance, avoiding agglomeration, and simple technical principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation process and steps in this embodiment are as follows:

[0021] 1. Weigh 7.88g (0.037mol) of citric acid (C 6 h 8 o 7 ) and 0.2727g (7.78×10 -4 mol) tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O);

[0022] 2. Measure 8mL (0.143mol) of ethylene glycol (C 2 h 6 o 2 ), put into the beaker;

[0023] 3. The weighed C 6 h 8 o 7 and SnCl 4 ·5H 2 Add O to ethylene glycol together, and stir rapidly for 10 minutes under the condition of 80°C water bath to dissolve it completely;

[0024] 4. Quickly add 1.5mL (4.41×10 -3 mol) tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ), then add about 15ml of deionized water, and stir rapidly for 1 hour in a water bath at 80°C until a transparent precursor sol is formed;

[0025] 5. Put the above transparent precursor sol into a closed reaction kettle and react in an oven at 200°C for 10 hours;

[0026] 6. Wash the solid product obtained by the reaction with deionized water and absolute ethanol for 4 times, and then ...

Embodiment 2

[0029] The preparation process and steps in this embodiment are as follows:

[0030] 1. Weigh 7.88g (0.037mol) of citric acid (C 6 h 8 o 7 ) and 0.5041g (1.89×10 -3 mol) sodium stannate (Na 2 SnO 3 ·3H 2 O);

[0031] 2. Measure 8mL (0.143mol) of ethylene glycol (C 2 h 6 o 2 ), put into the beaker;

[0032] 3. The weighed C 6 h 8 o 7 and SnCl 4 ·5H 2 Add O to ethylene glycol together, and stir rapidly for 10 minutes under the condition of 80°C water bath to dissolve it completely;

[0033] 4. Quickly add 1.5mL (4.41×10 -3 mol) tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ), then add about 20ml of deionized water, and stir rapidly for 1 hour in a water bath at 80°C until a transparent precursor sol is formed;

[0034] 5. Put the above transparent precursor sol into a closed reaction kettle and react in an oven at 200°C for 10 hours;

[0035] 6. Wash the solid product obtained by the reaction with deionized water and absolute ethanol for 4 times, and then dry it at ...

Embodiment 3

[0038] The preparation process and steps in this embodiment are as follows:

[0039] 1. Weigh 7.88g (0.037mol) of citric acid (C 6 h 8 o 7 ) and 1.0302g (2.94×10 -3 mol) tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O);

[0040] 2. Measure 8mL (0.143mol) of ethylene glycol (C 2 h 6 o 2 ), put into the beaker;

[0041] 3. The weighed C 6 h 8 o 7 and SnCl 4 ·5H 2 Add O to ethylene glycol together, and stir rapidly for 10 minutes under the condition of 80°C water bath to dissolve it completely;

[0042] 4. Quickly add 1.5mL (4.41×10 -3 mol) tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ), then add about 12ml of deionized water, and stir rapidly for 1 hour in a water bath at 80°C until a transparent precursor sol is formed;

[0043] 5. Put the above-mentioned transparent precursor sol into a closed reaction kettle, and react in an oven at 170°C for 13 hours;

[0044] 6. Wash the solid product obtained by the reaction with deionized water and absolute ethanol for 4 times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com