Method for preparing strontium titanate powder

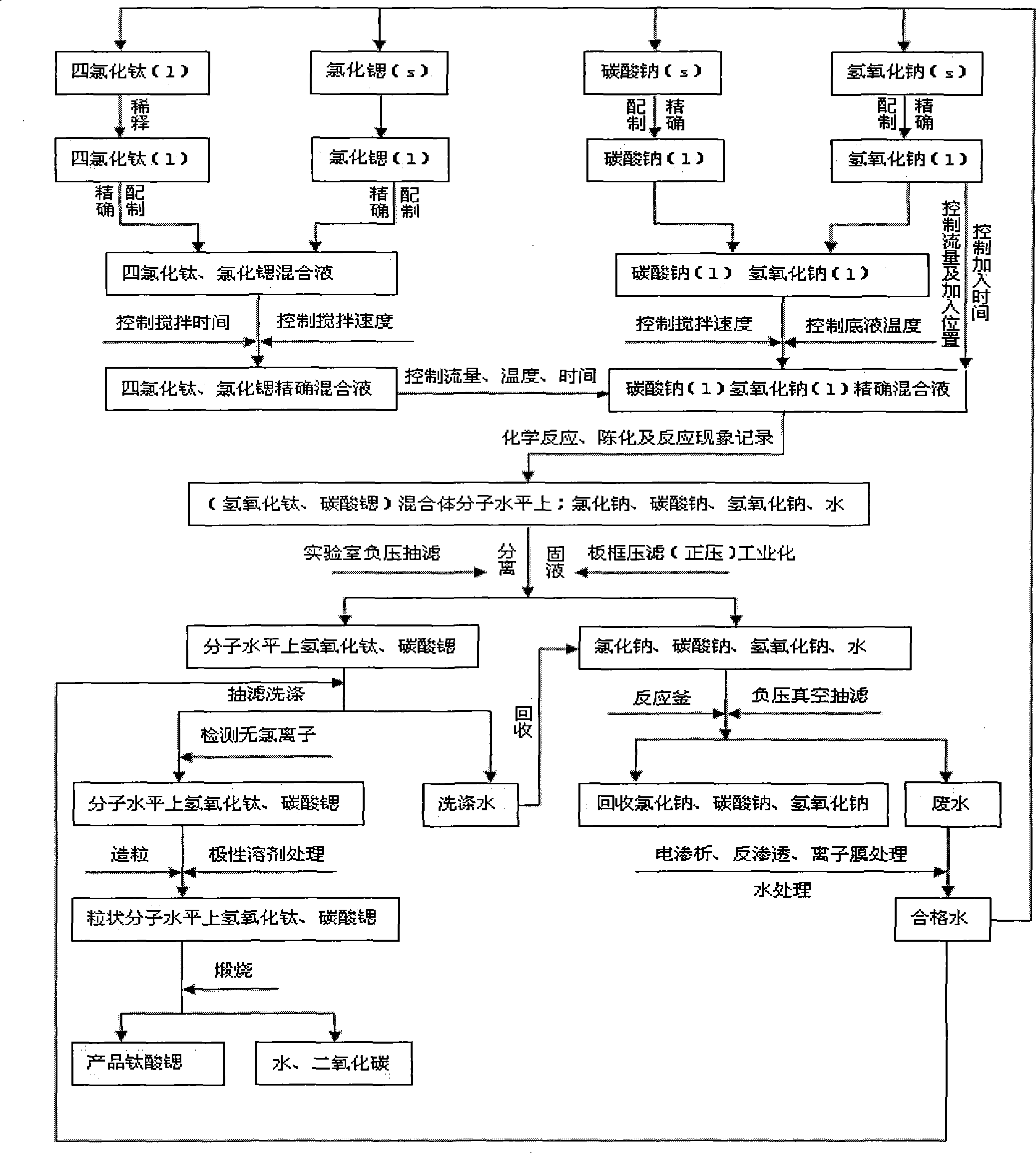

A technology of strontium titanate powder and titanium ions is applied in the field of preparing strontium titanate powder by chemical co-precipitation reaction, which can solve the problems of high equipment investment and maintenance costs, great harm to human body and environment, and increase of waste gas collection and recovery and treatment devices. and other problems, to achieve the effect of easy control of the reaction process, low equipment requirements, and good performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

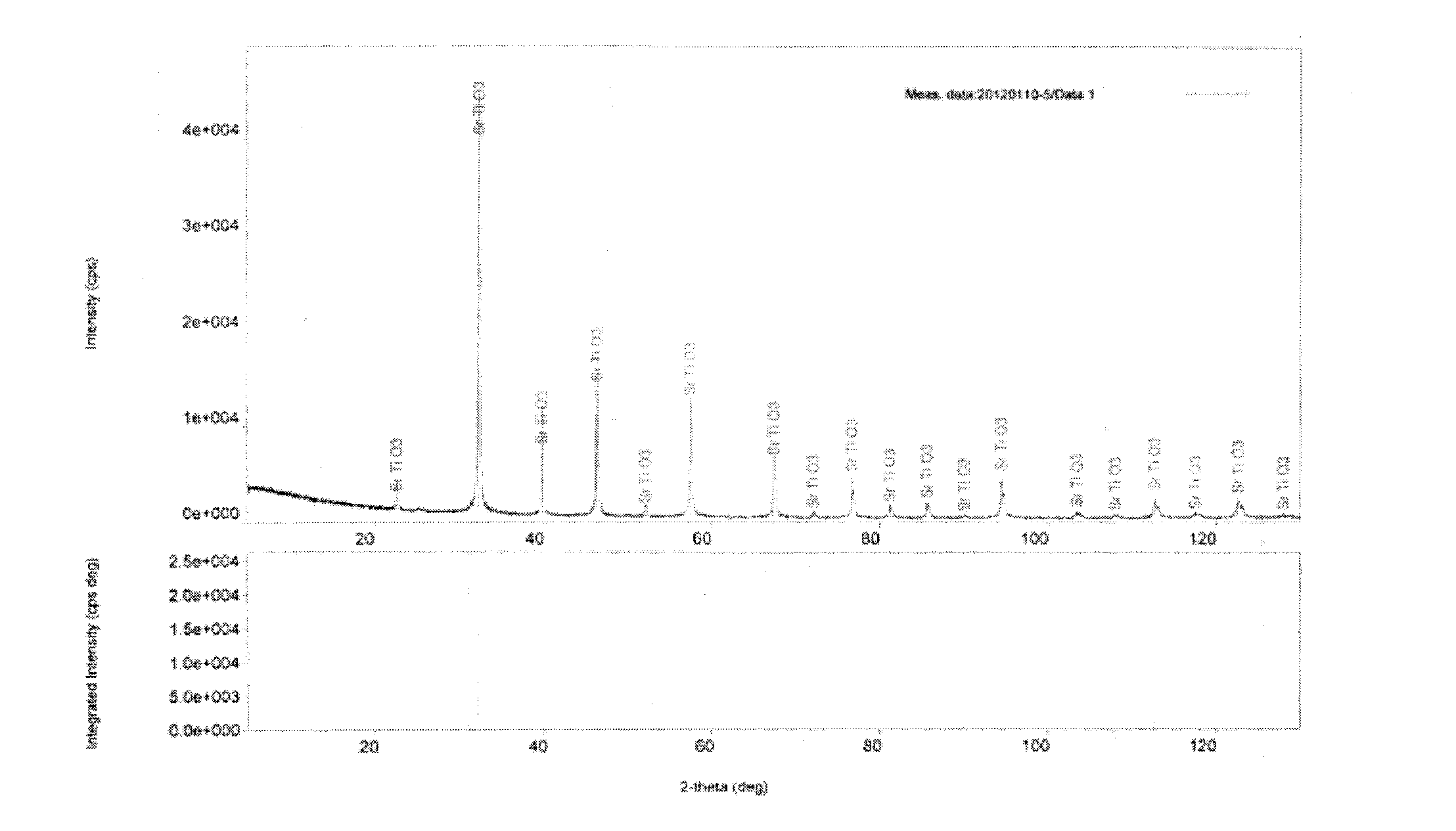

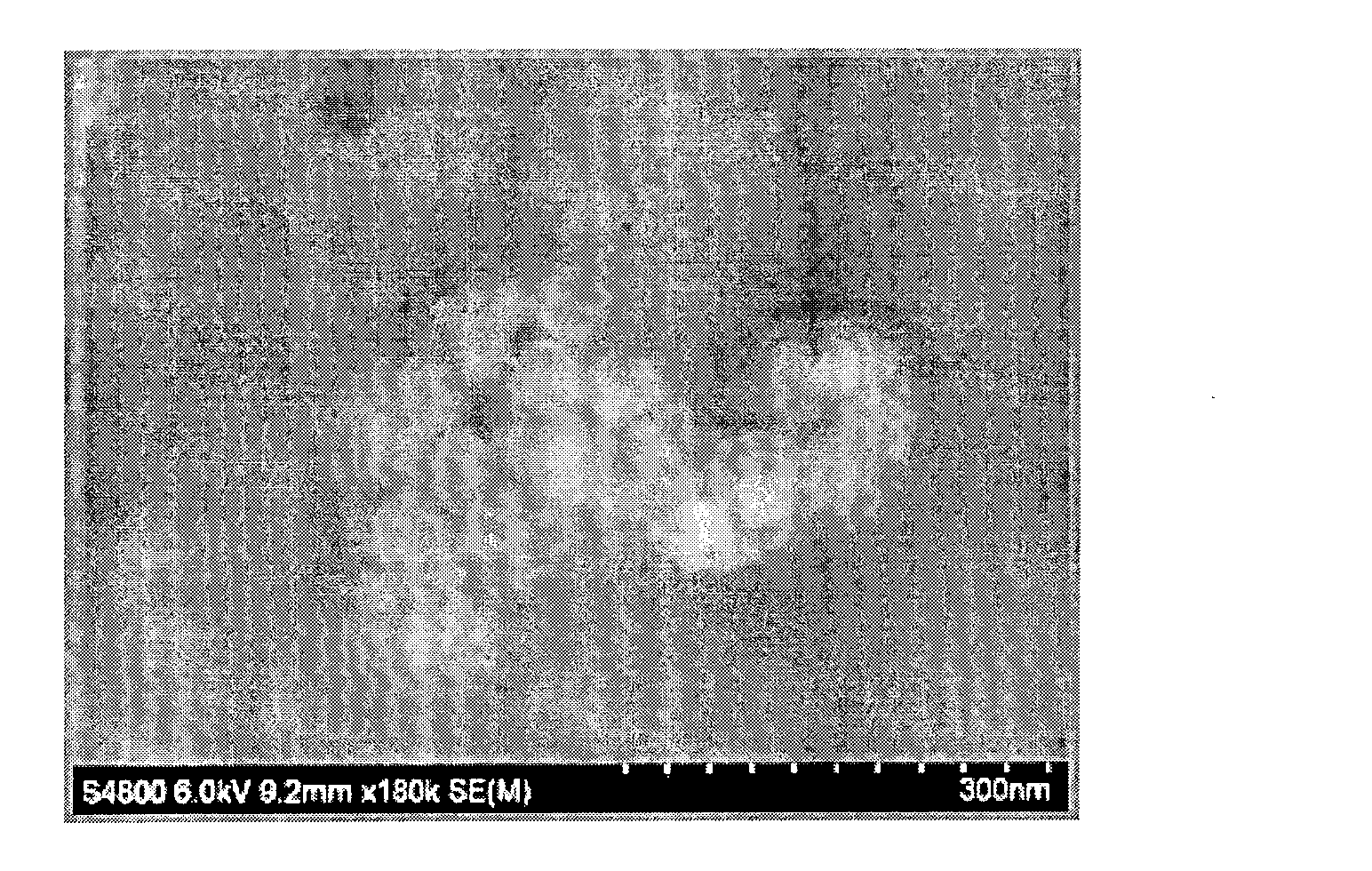

[0042] Accurately weigh 43.82g of strontium chloride hexahydrate and dissolve it in 327ml of water, the solution is transparent. Coarsely configure 2mol / L titanium tetrachloride solution, after calibration, accurately pipette the titanium tetrachloride solution according to the strontium-titanium molar ratio of 1.01, and prepare a mixed solution with a total concentration of strontium and titanium ions of 0.5mol / L. use. In the reaction vessel, add 15% Na 2 CO 3 Solution 162ml and 2mol / L sodium hydroxide solution 250ml, as precipitant solution. Under the condition of sufficient stirring, the strontium and titanium mixed solution was added into the reaction vessel at a speed of 2.6 ml / min. During the feeding process, check the pH value of the system, and finally add 90 ml of sodium hydroxide solution, the pH value of the solution is 10.2, the feeding time is 4 hours, fully reacted for 1 hour, and aged for 1 hour. The lotion adopts a low-concentration sodium bicarbonate dilut...

Embodiment 2

[0045] According to the preparation method in Example 1, the only difference is that the molar ratio of strontium and titanium ions is 1.02, and the total concentration is 0.6mol / L. The mixed solution is calcined at 880° C. for 6 hours.

Embodiment 3

[0047] Strontium chloride is prepared by reacting strontium carbonate with hydrochloric acid. Accurately weigh 24.46 g of strontium carbonate, dissolve and clear it with about 100 ml of 30% (volume ratio) HCl, and add water to dilute to 320 ml. Coarsely configure 2mol / L titanium tetrachloride solution, after calibration, accurately pipette the titanium tetrachloride solution according to the strontium-titanium molar ratio of 1.01, and prepare a mixed solution with a total concentration of strontium and titanium ions of 0.52mol / L. use. In the reaction vessel, add 15% Na 2 CO 3 Solution 162ml and 2mol / L sodium hydroxide solution 250ml, as precipitant solution. Under the condition of sufficient stirring, the strontium and titanium mixed solution was added into the reaction vessel at a speed of 2.5 ml / min. During the feeding process, check the pH value of the system, and finally add 90 ml of sodium hydroxide solution, the pH value of the solution is 10.2, the feeding time is 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com