Cashew novolac epoxy resin and preparation method thereof

A technology for phenolic epoxy resin and cashew phenolic resin, which is applied in the field of preparation of cardanol phenolic epoxy resin, can solve the problems of unstable performance, narrow ratio range, short pot life and the like, and achieves abundant and cheap raw materials, simple and convenient preparation method, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

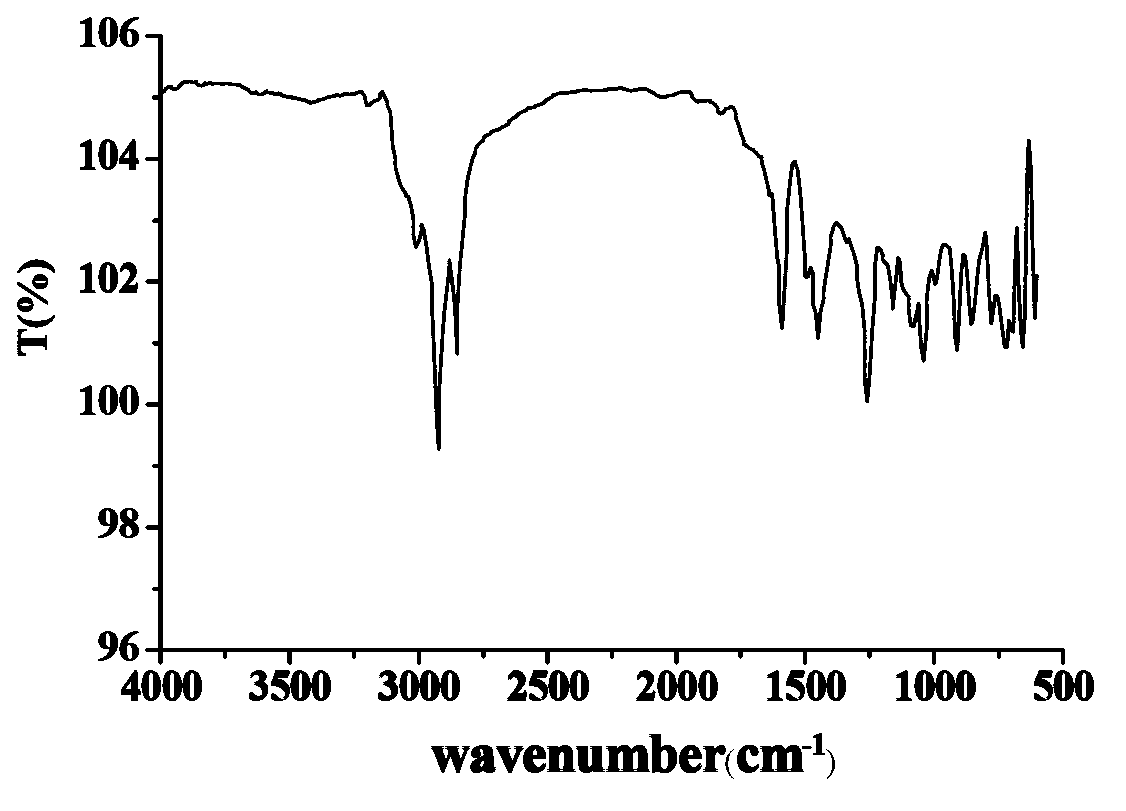

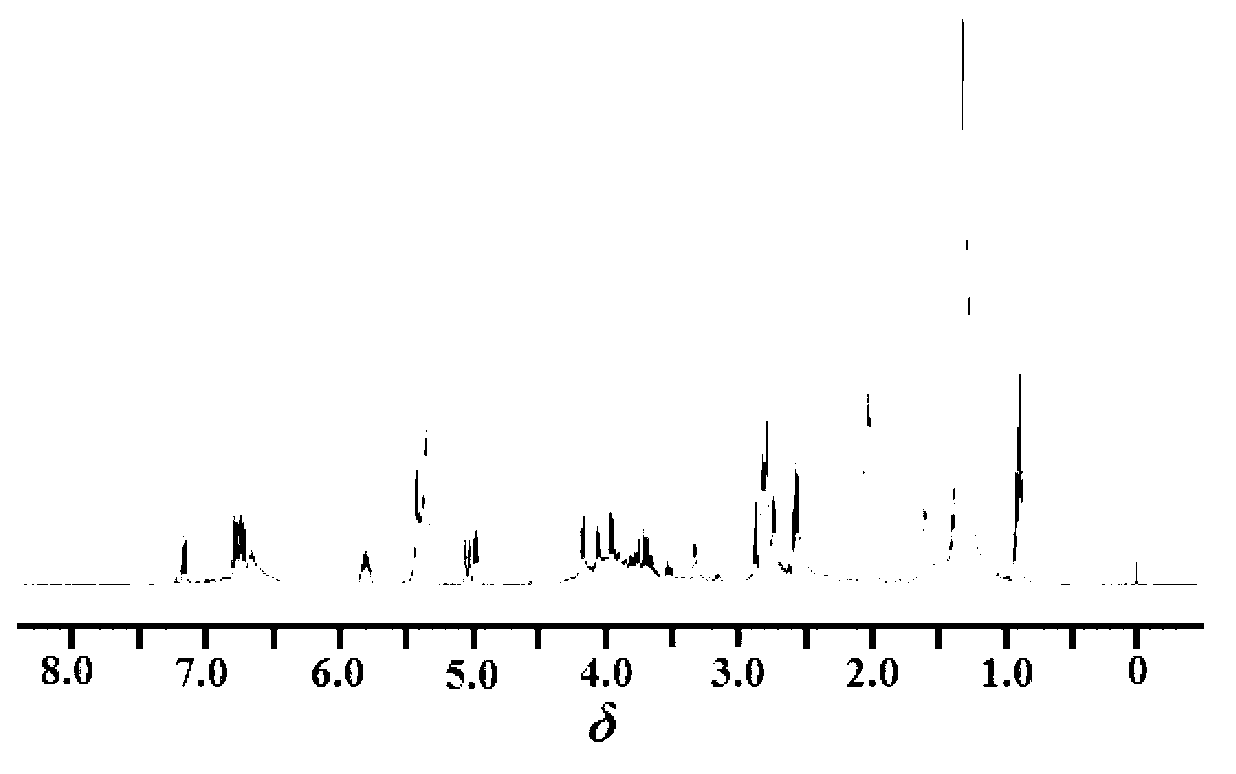

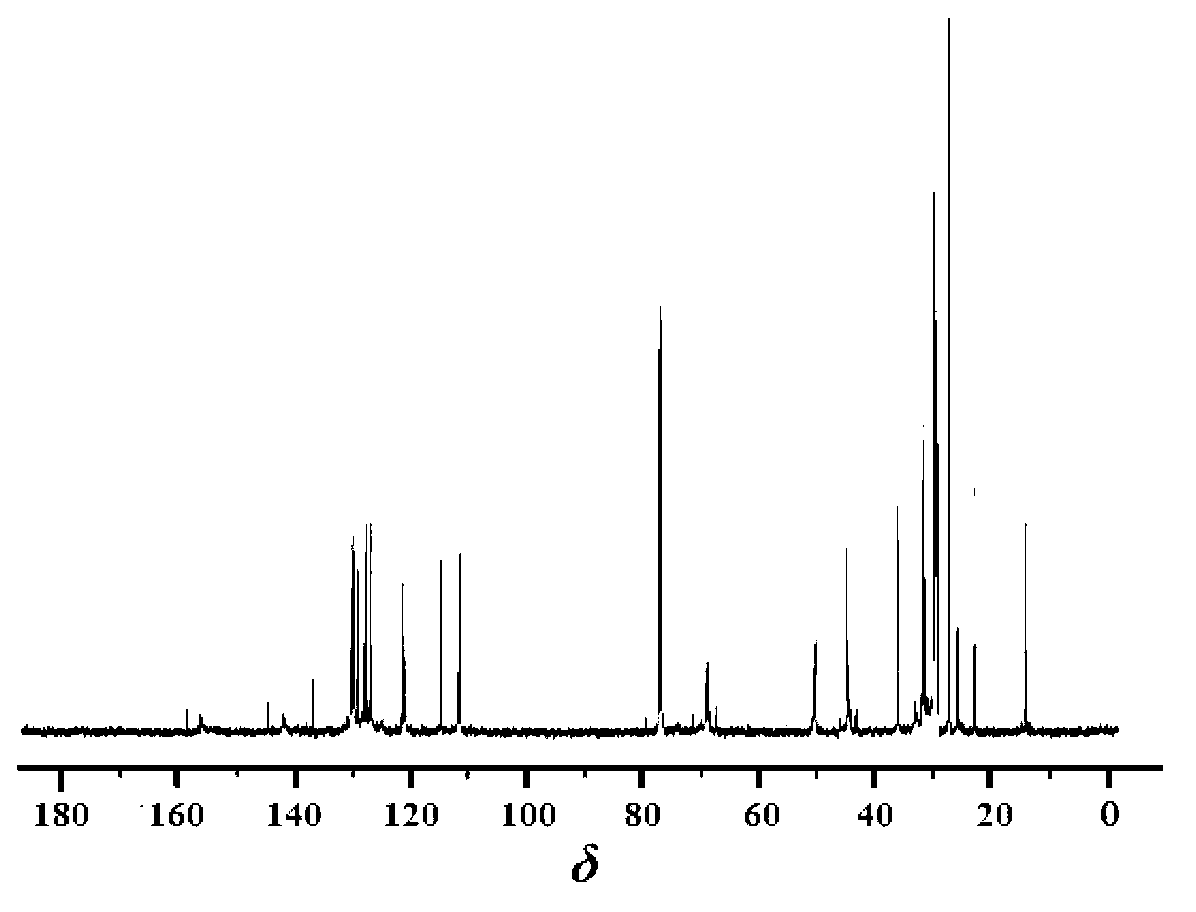

Image

Examples

preparation example Construction

[0030] The preparation method of this epoxy resin is realized through the following steps:

[0031] In the first step, under the action of a catalyst, react cardanol and formaldehyde at 70-100°C for 2-4 hours, wash with water, stand to separate layers, remove the water layer, and distill under reduced pressure to remove the remaining water to obtain a brown-red liquid cashew phenolic resin . Among them, the catalyst is any one of zinc acetate, oxalic acid, hydrochloric acid, and barium hydroxide, and the dosage is 1% to 3% of the mass of cardanol; formaldehyde is an aqueous solution with a mass concentration of 37%, and the dosage is 1% of the mass of cardanol. 0.5~1.0 times.

[0032] In the second step, under the catalysis of the quaternary ammonium salt, the above-mentioned cashew phenolic resin is reacted with epichlorohydrin at 80-120° C. for 4-5 hours. Wherein, the quaternary ammonium salt catalyst is benzyltriethylammonium chloride, tetramethylammonium chloride, tetrae...

Embodiment 1

[0036] In a four-neck flask equipped with a thermometer, a stirrer and a condenser, add 150.0g of cardanol and 4.5g of zinc acetate respectively, raise the temperature to 90°C under stirring, and slowly add 32.5g of 37% zinc acetate dropwise within 1h. Formaldehyde aqueous solution, reflux reaction for 3 hours, the product was washed with hot water, allowed to stand for stratification, the water layer was removed, and the remaining water was distilled off under reduced pressure to obtain a brown-red liquid cashew nut phenolic resin.

[0037]Add 100.0g of cashew phenolic resin, 308.4g of epichlorohydrin and 3.0g of benzyltriethylammonium chloride into a four-necked bottle equipped with a thermometer, agitator and condenser, stir and heat up to 100°C, and react for 4h. Then the temperature was lowered to 70°C, a total of 13.4 g of solid NaOH was added in batches within 2 hours, and the reaction was continued for 2 hours. Then wash with hot water until neutral, and distill off ex...

Embodiment 2

[0039] Add 150.0g of cardanol and 4.5g of zinc acetate to a four-necked flask equipped with a thermometer, a stirrer and a condenser tube, raise the temperature to 100°C under stirring, and slowly add 32.5g of 37% zinc acetate dropwise within 1 hour. Formaldehyde aqueous solution, reflux reaction for 3 hours, the product was washed with hot water, allowed to stand for stratification, the water layer was removed, and the remaining water was distilled off under reduced pressure to obtain a brown-red liquid cashew nut phenolic resin.

[0040] Add 100.0g of cashew phenolic resin, 308.4g of epichlorohydrin and 3.0g of benzyltriethylammonium chloride into a four-necked bottle equipped with a thermometer, agitator and condenser, stir and heat up to 100°C, and react for 4h. Then the temperature was lowered to 70°C, a total of 14.0 g of solid NaOH was added in batches within 2 hours, and the reaction was continued for 2 hours. Then wash with hot water until neutral, and distill off exc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com