High-cohesiveness polyester film, method for preparing same as well as solar cell back panel

A polyester film, high adhesion technology, applied in the field of polyester film, can solve the problem of delamination or peeling off of solar back film, and achieve the effects of avoiding peeling, good adhesion, and increasing polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

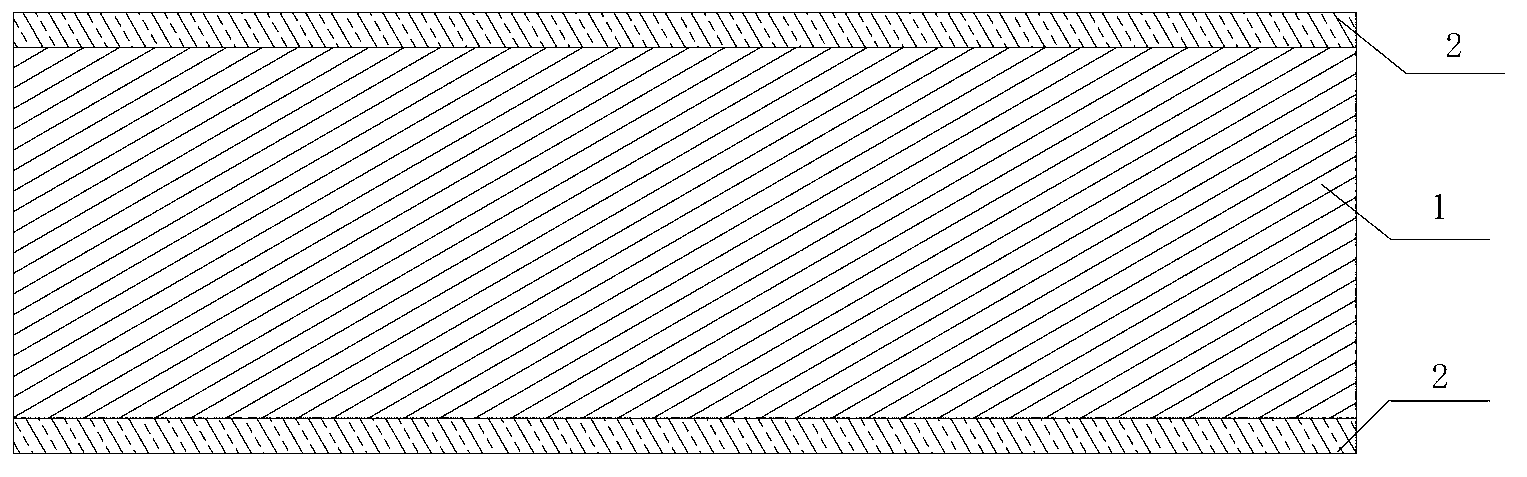

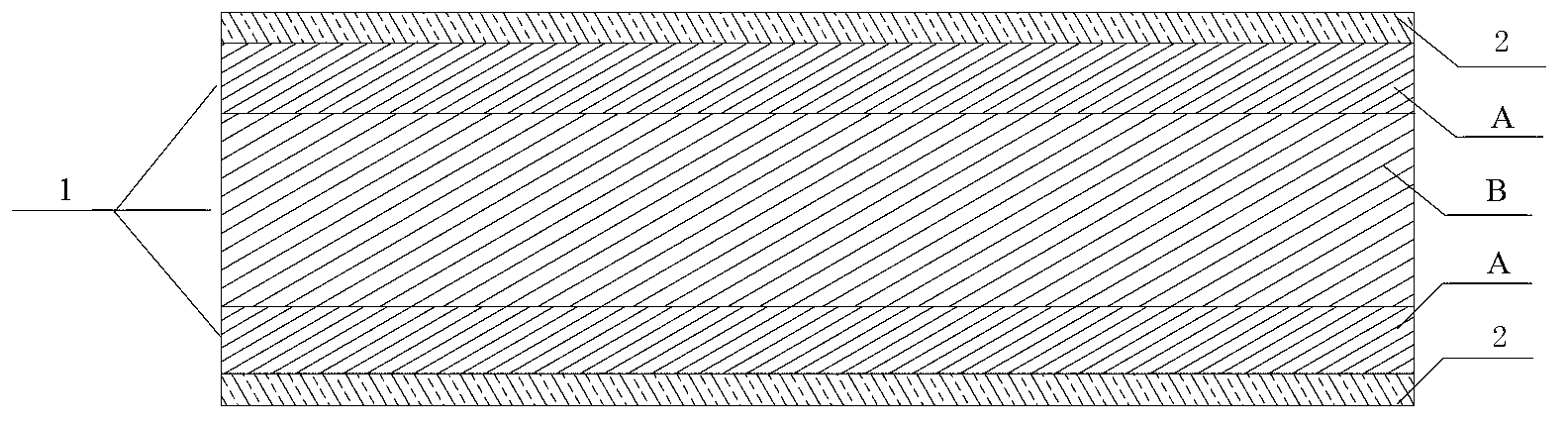

Image

Examples

preparation example Construction

[0041] The preparation method of the high adhesiveness polyester film provided by the invention comprises the steps:

[0042] (1) Put the polyester chip and modified masterbatch into the crystallization drying tower to dry, and after drying, enter the extruder to melt and extrude, cool the cast sheet, and stretch it longitudinally;

[0043] (2) Coating the ethyl acetate solution of maleic anhydride and hydroxyethyl methacrylate online, and coating the solution on the upper and lower surfaces of the substrate obtained in step (1), with a coating thickness of 0.1-5 μm;

[0044] (3) The base material obtained in step (2) is subjected to transverse stretching, heat setting treatment, microwave modification and grafting treatment, winding, and cutting to obtain the high-adhesive polyester film.

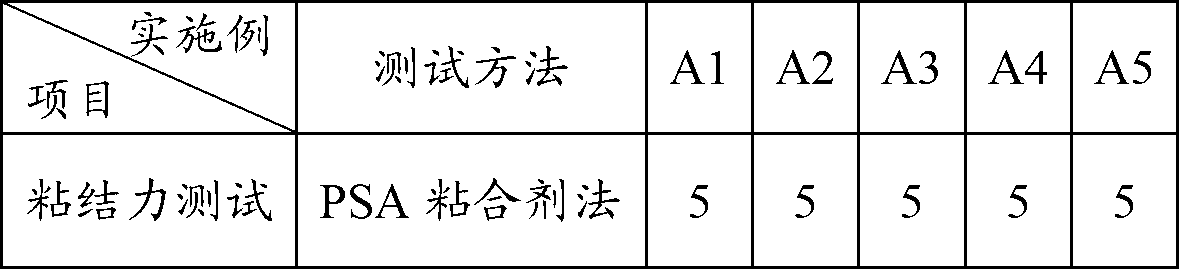

[0045] Prepare high adhesiveness polyester film according to above-mentioned method, the method for testing its adhesiveness is as follows:

[0046] Form a pressure-sensitive adhesive layer...

Embodiment 1

[0052] Configure the ethyl acetate solution of maleic anhydride and hydroxyethyl methacrylate; the weight ratio of maleic anhydride and hydroxyethyl methacrylate is 3:7, and in the solution, maleic anhydride and hydroxyethyl methacrylate The content of ethyl ester is 50%; the modified polyester masterbatch is prepared by a twin-screw granulator, and the obtained modified masterbatch contains 50% rutile titanium dioxide with a particle size of 0.3 μm, and 5% rutile titanium dioxide with a particle size of 2 μm. Silicon and 45% film grade polyester chips.

[0053] Prepare high-adhesive polyester film according to the above method, put 100 parts by weight of polyester chips and 5 parts by weight of modified masterbatch into a crystallization drying tower at 160 ° C for 4-5 hours, when polyester chips and modified When the moisture content of the masterbatch is lower than 50ppm, enter the extruder to melt and extrude at 260-280°C, pass through a 150-mesh filter for coarse filtrati...

Embodiment 2

[0055] Configure the ethyl acetate solution of maleic anhydride and hydroxyethyl methacrylate; the weight ratio of maleic anhydride and hydroxyethyl methacrylate is 2:3, and in the solution, maleic anhydride and hydroxyethyl methacrylate The content of ethyl ester is 30%; the modified masterbatch is prepared, and the obtained modified masterbatch contains 50% zinc oxide with a particle size of 0.5 μm, 8% silica with a particle size of 1.5 μm and 42% film-grade polyester chips .

[0056] Prepare high-adhesive polyester film according to the above method, put 100 parts by weight of polyester chips and 10 parts by weight of modified masterbatch into a crystallization drying tower at 160 ° C for 4-5 hours, when polyester chips and modified When the moisture content of the masterbatch is lower than 50ppm, it enters the extruder, melts and extrudes at 260-280°C, passes through a 150-mesh filter for coarse filtration, and a 400-mesh filter for fine filtration. Cool the cast sheet wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com