Device and method for producing biodiesel with illegal cooking oil and waste engine oil

A biodiesel and waste engine oil technology, which is applied in the preparation of biological raw materials, biofuels, liquid hydrocarbon mixtures, etc., can solve the problems of a large amount of waste water and saponification, reduce the quality of biodiesel, and affect the injection schedule, so as to reduce water washing and The process of decolorization treatment, reducing the steps of washing treatment, and the effect of good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

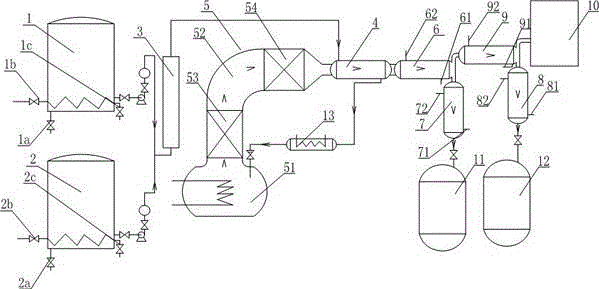

[0028] Such as figure 1 As shown, the device for preparing biodiesel from waste oil and waste engine oil according to the present invention includes a waste oil settling tank 1, a waste engine oil settling tank 2, a mixer 3, a heat exchanger 4, a tower-type fixed-bed reactor 5, and a condensation system , gas storage tank 10, diesel oil tank 11 and gasoline tank 12, described waste oil settling tank 1 and waste engine oil settling tank 2 are respectively connected with mixer 3, and described mixer 3 is connected with heat exchanger 4, and described heat exchange The reactor 4 is connected with the reaction kettle 51 at the lower part of the tower-type fixed-bed reactor 5 through the preheater 13 .

[0029] The lower part of the tower-type fixed-bed reactor 5 is an electrically heated high-temperature reactor 51, and the upper end of the reactor is connected to a tubular fixed-bed reactor 52, and the tubular fixed-bed reactor is divided into a primary reactor 53 and a secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com