Production method of recombinant phospholipase D

A production method, phospholipase technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of more PLD inclusion bodies, less PLD inclusion bodies, and low fermentation enzyme activity, so as to increase the culture density , optimization of fermentation process conditions, and the effect of high-density fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Construct recombinant genetically engineered bacteria, which is recombinant E. coli expressing phospholipase D; the plasmid used is the pET system plasmid pET-32(a) developed by Merck; the host bacteria used is developed by Merck. BL21 series Escherichia coli BL21(DE3)pLysS; the phospholipase D gene used is derived from the microorganism Streptomyces.

[0061] Prepare shake flask seed culture medium and fermentation medium, the composition of shake flask seed culture medium comprises glycerol 10g / L, tryptone 20g / L, yeast extract 10g / L, disodium hydrogen phosphate 5.5g / L and ampicillin sodium 40mg / L L, the above items were dissolved in deionized water, and the volume was adjusted to 1L, and the pH value was adjusted to 7 with hydrochloric acid or sodium hydroxide.

[0062] Activate the constructed recombinant genetically engineered bacteria on the plate for 18 hours, then pick the activated genetically engineered bacteria on the plate and inoculate them into shake flasks...

Embodiment 2

[0067] Production of recombinant PLD.

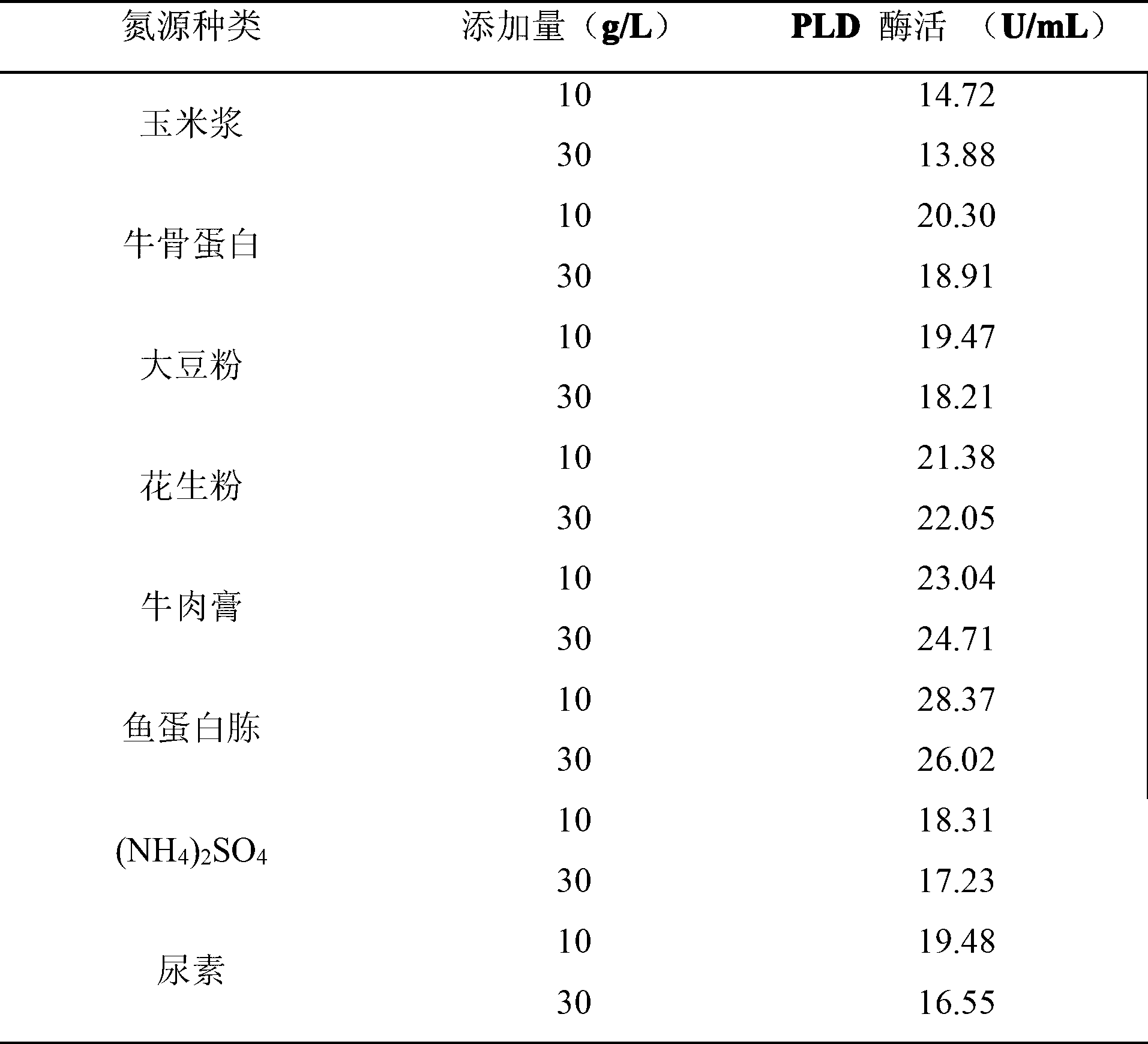

[0068] According to 10.0% of the volume of the fermentation medium, the seed solution was added, and the composition of the fermentation medium was dextrin 50g / L, fish peptone 30g / L, angel yeast extract 15g / L, basic salt 50mL / L, trace elements 30mL / L, Ampicillin sodium 100mg / L. At 28°C, the pH was controlled to be 6.5, and the dissolved oxygen was 30% for fermentation and cultivation. When the OD600 was 0.5, lactose was added to the fermentation broth until its final concentration in the fermentation broth was 1.0%, and then controlled at 20°C. The pH value is 7.0, the dissolved oxygen is 20%, and the fermentation is continued for 32 hours. The PLD is obtained from the fermentation broth according to the conventional method, and the enzyme activity is 18.05U / mL 发酵液 . Other parts are identical with embodiment 1.

Embodiment 3

[0070] Production of recombinant PLD.

[0071] Add the seed solution according to 5.0% of the volume of the fermentation medium, and the composition of the fermentation medium is dextrin 30g / L, fish peptone 20g / L, angel yeast extract 10g / L, basic salt 30mL / L, trace elements 20mL / L, Ampicillin sodium 50mg / L. At 28°C, the pH was controlled to be 6.5, and the dissolved oxygen was 30% for fermentation and cultivation. When the OD600 was 0.5, lactose was added to the fermentation broth until its final concentration in the fermentation broth was 1.0%, and then controlled at 20°C. The pH value is 7.0, the dissolved oxygen is 20%, and the fermentation is continued for 32 hours. The PLD is obtained from the fermentation broth according to the conventional method, and the enzyme activity is 24.36U / mL 发酵液 . Other parts are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com