Lithium manganate material for surface treatment and preparation method thereof

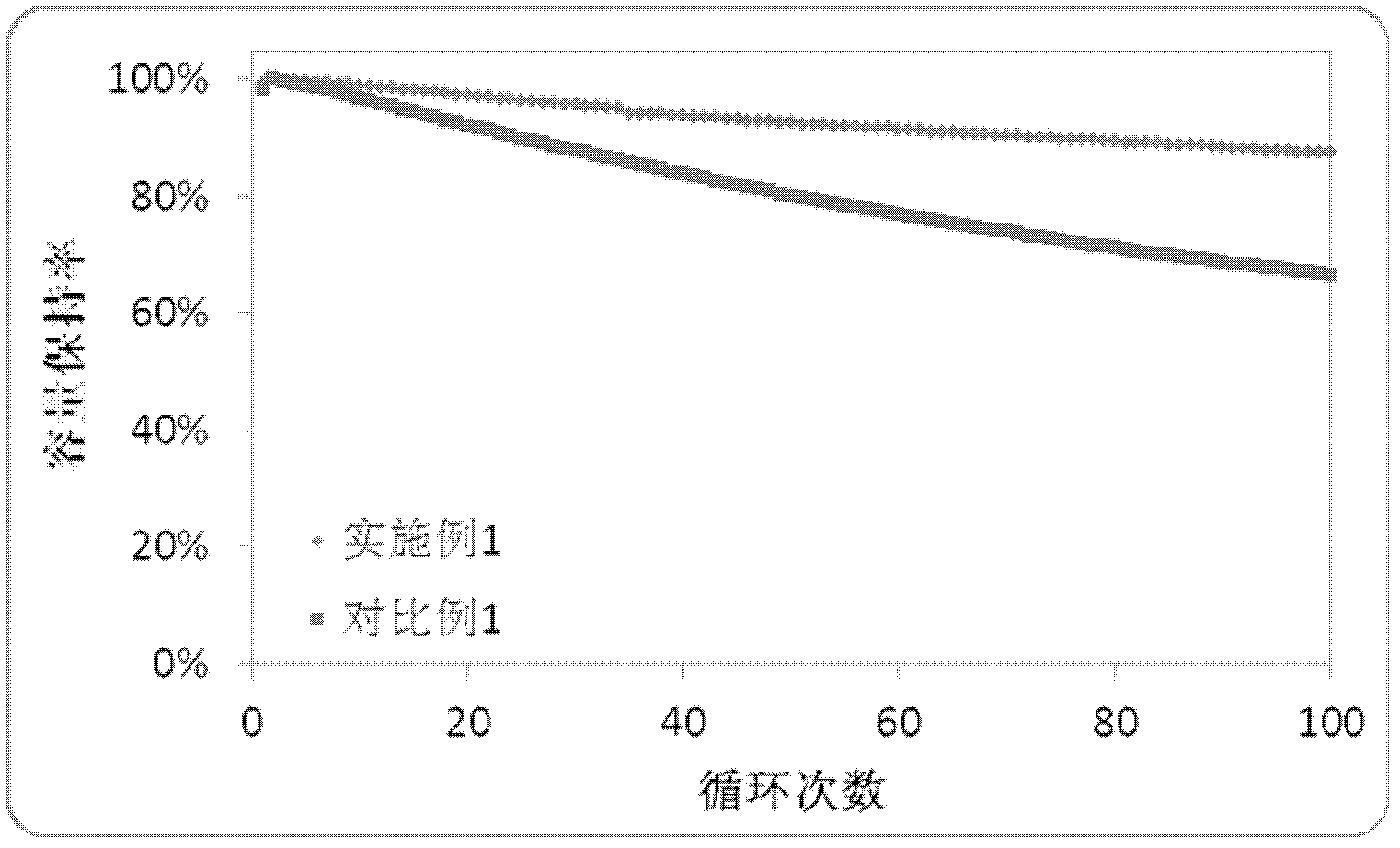

A surface treatment, lithium manganate technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as the inability of coating elements to form concentration gradients, uneven dispersion of coatings, and failure to achieve coating effects. The effect of improving high temperature cycling performance and high temperature storage performance, improving bulk phase stability and surface stability, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

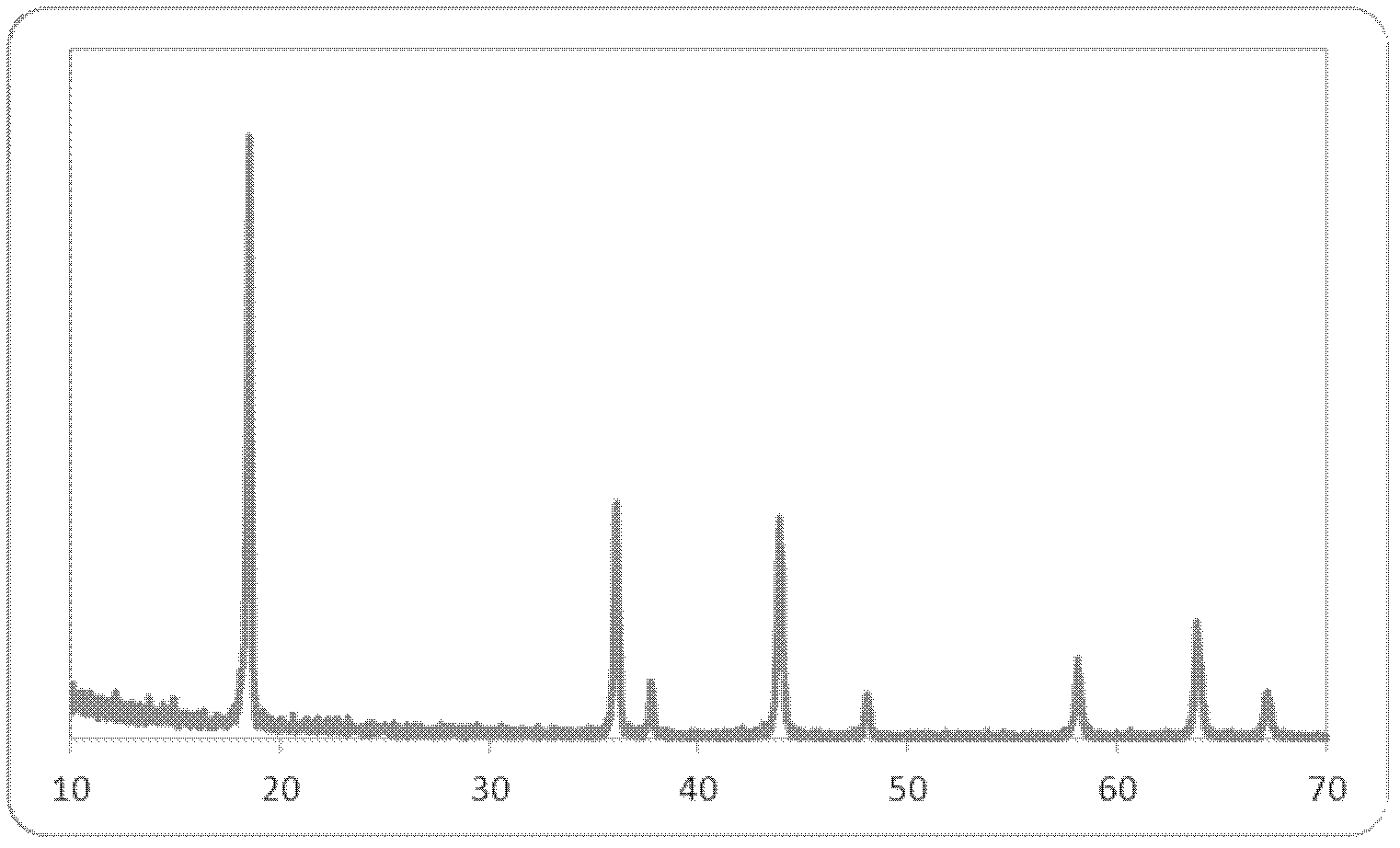

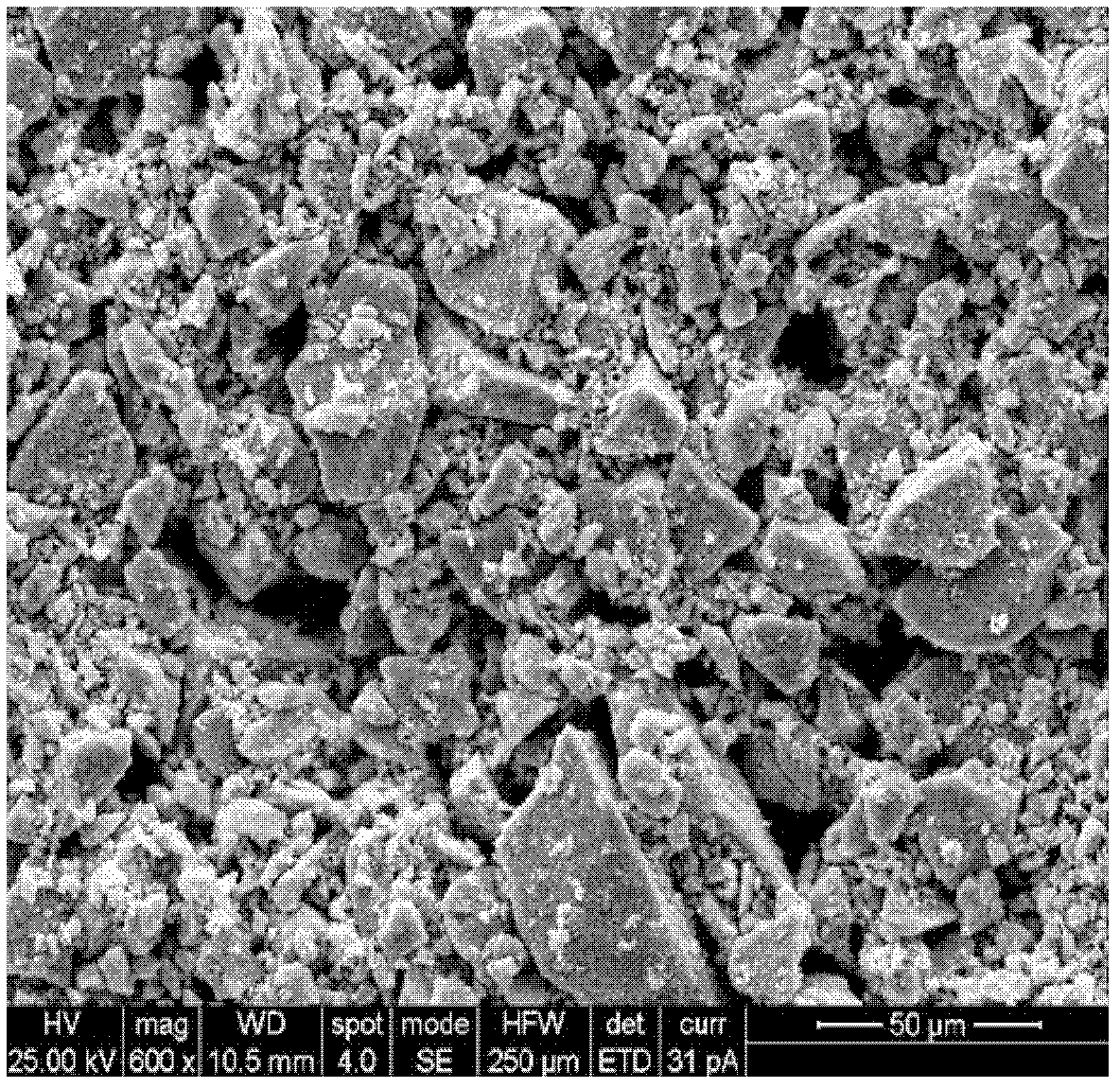

[0028] A lithium manganate material is a lithium manganate material that is surface-treated on doped and modified lithium manganate. The surface treatment material is glycol titanate chelate.

[0029] A preparation method of lithium manganate material, comprising the steps of:

[0030] (1) Weigh a certain amount of lithium hydroxide, electrolytic manganese dioxide, and calcium carbonate according to the molar ratio of Li:Mn:Ca of 1.15:1.90:0.10, place them in a mixing tank and mix them for 6 hours, and mix the homogeneous materials in Sinter at 850°C for 20 hours, cool naturally to room temperature, crush and sieve to obtain doped and modified lithium manganate.

[0031] (2) In the drying room, the molar ratio of Ti:(Mn+M) is 0.05%, the mass ratio of isopropanol to lithium manganate is 1:1, and the glycol titanate chelate is dissolved in isopropanol , add the lithium manganate material to the solution, and mix well. The homogeneously mixed slurry is spray-dried by means of ...

Embodiment 2

[0040] A lithium manganate material is a lithium manganate material that is surface-treated on doped and modified lithium manganate. The surface treatment material is aluminum acetylacetonate.

[0041]A preparation method of lithium manganate material, comprising the steps of:

[0042] (1) Take by weighing a certain amount of lithium carbonate, manganese acetate, vanadium pentoxide, ammonium sulfide by Li: Mn: V: S molar ratio is 0.95: 1.8: 0.2: 0.05, is placed in mixing tank and mixes for 5 hours, The uniformly mixed material was sintered at 700°C for 18 hours, cooled naturally to room temperature, crushed and sieved to obtain the doped modified lithium manganate.

[0043] (2) In the drying room, according to Ti: (Mn+M) molar ratio is 5%, ethanol and lithium manganate mass ratio is 90: 1, aluminum acetylacetonate is dissolved in ethanol, lithium manganate material is added to the solution, Mix well. The homogeneously mixed slurry is spray-dried in a spray-drying manner, an...

Embodiment 3

[0046] A lithium manganate material is a lithium manganate material that is surface-treated on doped and modified lithium manganate. The surface treatment material is polybutyl titanate.

[0047] A preparation method of lithium manganate material, comprising the steps of:

[0048] (1) Weigh a certain amount of lithium oxalate, manganese sulfate, and zinc fluoride according to the molar ratio of Li:Mn:Zn and F of 1.00:1.95:0.05:0.10, place them in a mixing tank and mix them for 6 hours, and mix the The material was sintered at 1000°C for 11 hours, cooled naturally to room temperature, crushed and sieved to obtain the doped modified lithium manganate.

[0049] (2) In the drying room, according to Ti:(Mn+M) molar ratio is 9%, ethyl acetate and lithium manganate mass ratio is 5:1, polybutyl titanate is dissolved in ethyl acetate, manganic acid Lithium material is added to the solution and mixed well. The uniformly mixed slurry is spray-dried by means of spray drying, and the et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com