Light granite facing heat-preservation fire-prevention plate product and fabrication method thereof

A technology of granite and fireproof board, applied in the field of fireproof materials, can solve the problems of complex preparation method, application limitation, pollution, etc., and achieve the effects of wide source of raw materials, low manufacturing cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Press the volcanic powder to make a lightweight board, spray the water-based reactive epoxy acrylic acid modified polymer material on the board, bake and cure, the curing temperature is 80°C, and the curing time is 5 minutes;

[0058] (2) Spray the coloring layer mixture, bake and cure, the curing temperature is 120°C, and the curing time is 12 minutes. The coloring layer mixture is composed of 1wt% natural cinnabar and 99wt% water-based reactive silicone modified polyurethane polymer material ;

[0059] (3) Spray the protective surface layer mixture, bake and cure, the curing temperature is 150°C, and the curing time is 15 minutes. The protective surface layer is composed of 0.2wt% alumina and 99.8wt% reactive silicone modified water-based aliphatic Polyurethane composition.

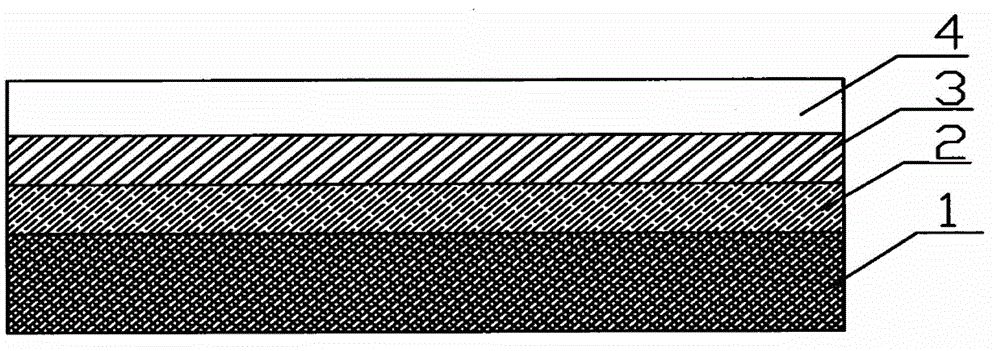

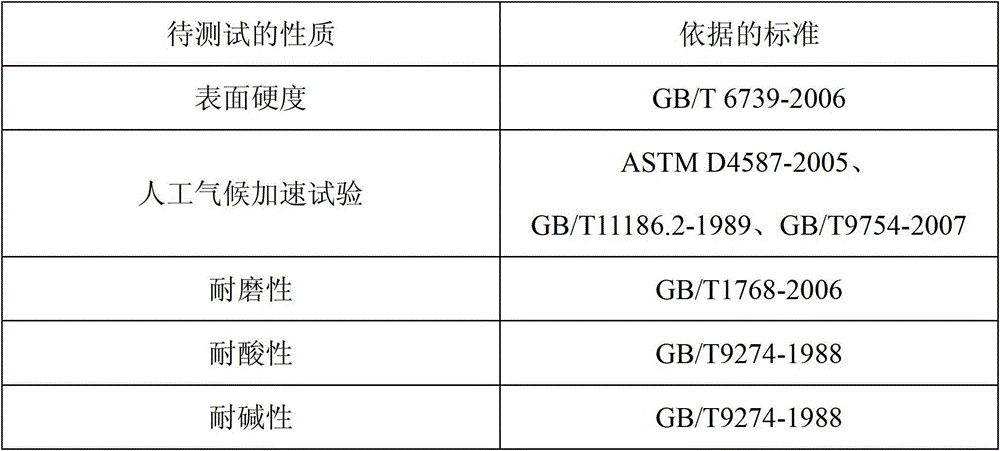

[0060] The structure of the thermal insulation and fireproof board products is as follows: figure 1 shown. After testing, the surface hardness of the obtained thermal insulation and firepr...

Embodiment 2

[0062] (1) Compress the mixture of vermiculite powder and volcanic powder to make a lightweight board, spray the water-based reactive epoxy acrylic acid modified polymer material on the lightweight board, bake and cure, the curing temperature is 85°C, and the cured The time is 4 minutes;

[0063] (2) Spray the coloring layer mixture, bake and cure, the curing temperature is 115°C, and the curing time is 17 minutes. The coloring layer mixture is composed of 0.05wt% natural red clay and 99.95wt% water-based reactive silicone-modified polyurethane polymer Material composition;

[0064] (3) Spray the protective surface layer mixture, bake and cure, the curing temperature is 150°C, and the curing time is 15min. The protective surface layer mixture is composed of 6wt% alumina, 1.5% anti-ultraviolet absorber and 92.5wt% reactive type Silicone modified waterborne aliphatic polyurethane composition.

[0065] After testing, the surface hardness of the obtained thermal insulation and f...

Embodiment 3

[0067] (1) Press the mixture of hollow glass beads and perlite to make a lightweight board, spray the water-based reactive epoxy acrylic modified polymer material on the lightweight board, bake and cure, and the curing temperature is 82°C. The curing time is 8 minutes;

[0068] (2) Spray the coloring layer mixture, bake and cure, the curing temperature is 120°C, and the curing time is 15 minutes. The coloring layer mixture is composed of 0.7wt% natural realgar and 99.3wt% water-based reactive silicone-modified polyurethane polymer Material composition;

[0069] (3) Spray the protective surface layer mixture, bake and cure, the curing temperature is 160 ° C, and the curing time is 10 minutes. The protective surface layer mixture is composed of 0.4wt% alumina, 1.2% anti-ultraviolet Composed of electrostatic agent and 97.4wt% reactive silicone modified waterborne aliphatic polyurethane.

[0070] After testing, the surface hardness of the obtained thermal insulation and fireproo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com