Silane cross-linking polyethylene insulation material capable of bearing temperature of 125 DEG C and preparation method thereof

A polyethylene insulating material and silane cross-linking technology, applied in organic insulators, plastic/resin/wax insulators, etc., can solve problems such as application limitations, improve heat resistance, maintain electrical and mechanical properties, and economic applicability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

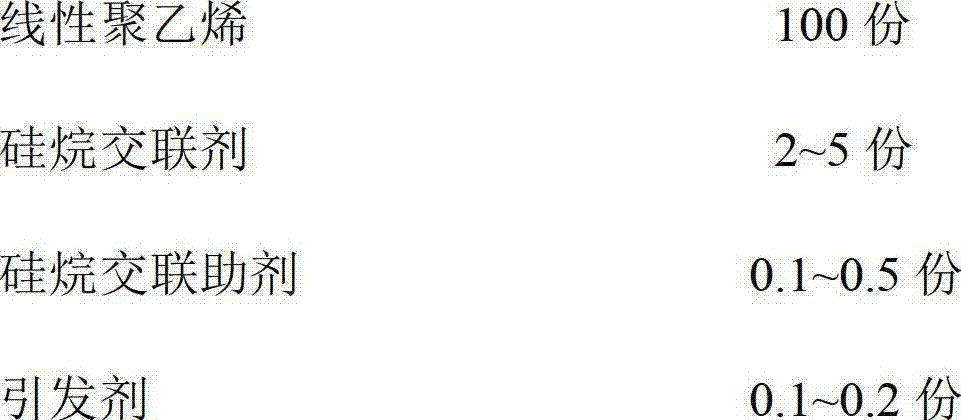

[0037] Material A:

[0038]

[0039] Reactive extrusion granulation by twin-screw extruder, drying after cooling to obtain material A;

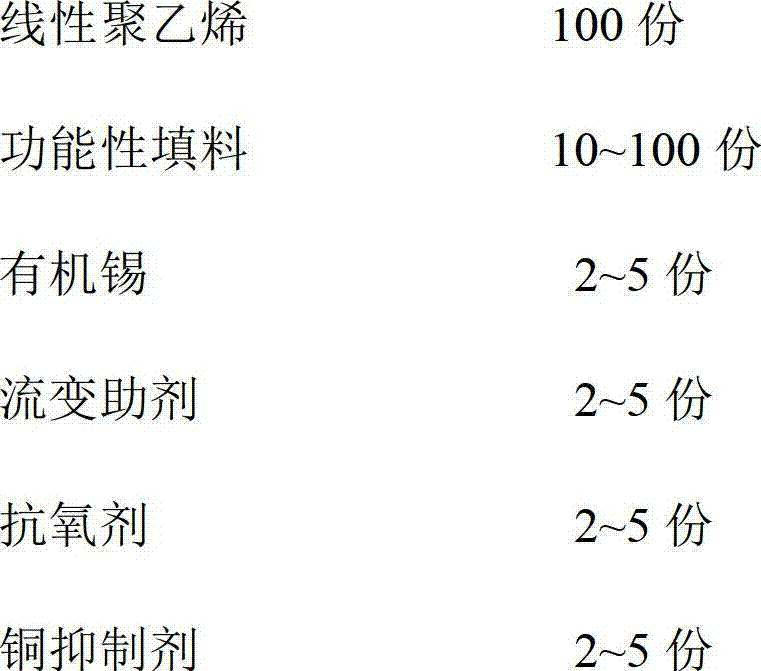

[0040] Material B:

[0041]

[0042] Blending and granulation by a twin-screw extruder, air cooling, and drying to obtain material B.

[0043] Mix according to the ratio of material A: material B = 90:10 to obtain a silane cross-linked polyethylene insulating material with a temperature resistance of 125°C. The JB / T10437-2004 standard was used for testing, and the results are shown in Table 1.

Embodiment 2

[0045] Material A:

[0046]

[0047] Reactive extrusion granulation by twin-screw extruder, drying after cooling to obtain material A;

[0048] Material B:

[0049]

[0050] Antioxidant 300 1 part, Antioxidant 1076 1 part

[0051] 2 parts of copper inhibitor bis(3,5-di-tert-butyl-4-hydroxyphenylpropionoyl)hydrazine.

[0052] Blending and granulation by a twin-screw extruder, air cooling, and drying to obtain material B.

[0053] Mix according to the ratio of material A: material B = 95:10 to obtain a temperature-resistant 125°C silane cross-linked polyethylene cable material. The JB / T10437-2004 standard was used for testing, and the results are shown in Table 1.

Embodiment 3

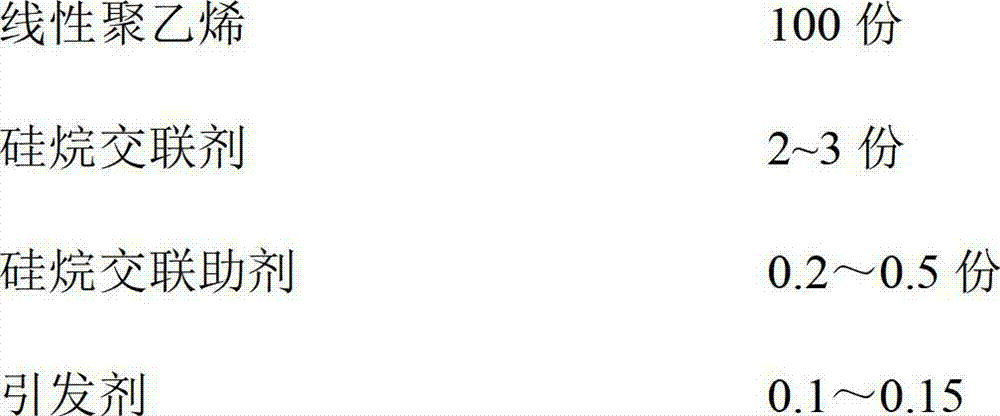

[0055] Material A:

[0056]

[0057] Reactive extrusion granulation by twin-screw extruder, drying after cooling to obtain material A;

[0058] Material B:

[0059]

[0060]

[0061] 2 parts of copper inhibitor bis(3,5-di-tert-butyl-4-hydroxyphenylpropionoyl)hydrazine.

[0062] Blending and granulation by a twin-screw extruder, air cooling, and drying to obtain material B.

[0063] Mix according to the ratio of material A: material B = 90:10 to obtain a silane cross-linked polyethylene insulating material with a temperature resistance of 125°C. The JB / T10437-2004 standard was used for testing, and the results are shown in Table 1.

[0064] The temperature-resistant 125°C silane cross-linked polyethylene insulating material prepared in the above three examples has excellent mechanical and electrical properties, good heat resistance and reliable performance.

[0065]Table 1 Example performance test results

[0066]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com