Amino acid micro-fertilizer and preparation method thereof

An amino acid and micro-fertilizer technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of ineffective treatment of iron deficiency in plants, and achieve the effects of flexible application methods, improved soil structure, and high nutrient availability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

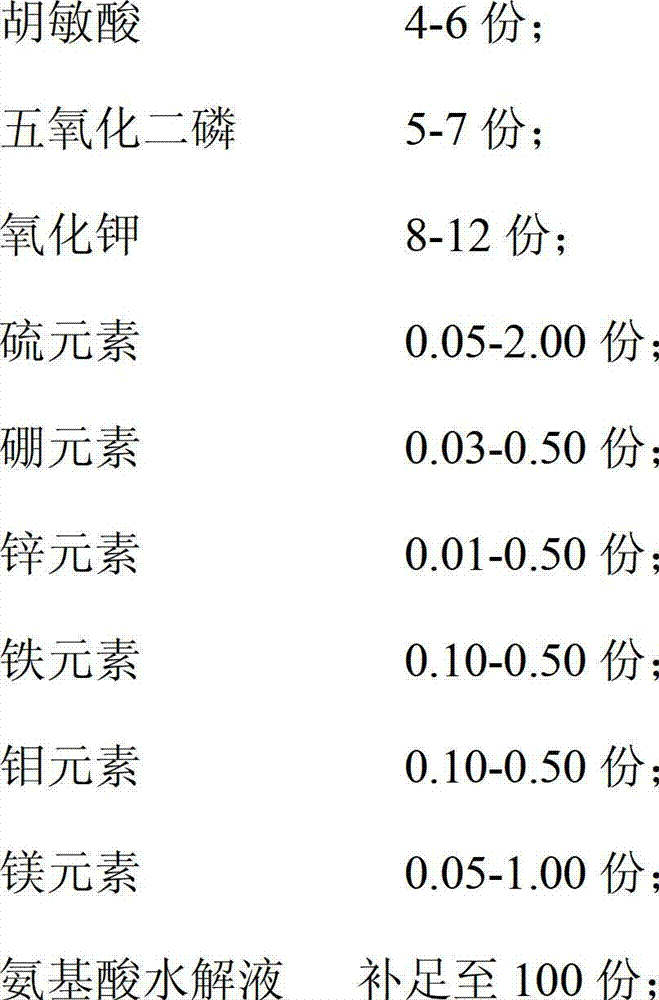

[0026] An amino acid micro-fertilizer, consisting of the following raw materials in weight percentage: 4 parts of humic acid, 7 parts of phosphorus pentoxide, 8 parts of potassium oxide, 2.00 parts of sulfur element, 0.03 part of boron element, 0.50 part of zinc element, and 0.1 part of iron element part, 0.5 part of molybdenum element, 0.05 part of magnesium element, and 77.82 parts of amino acid hydrolyzate; the content of amino acid in the described amino acid hydrolyzate is 35%.

[0027] The preparation method of described amino acid micro-fertilizer comprises the following steps:

[0028] (1) Preparation of amino acid hydrolyzate: take discarded keratin from human body and animals, put the keratin into the ceramic tank, compact it, add 31% hydrochloric acid solution to fully soak; use water vapor above 100°C to Heat the outer vat of the pottery vat and react for 10 hours; when the pH value of the solution in the inner vat is adjusted to 7 with sodium hydroxide, the filter...

Embodiment 2

[0039] An amino acid micro-fertilizer, consisting of the following raw materials in parts by weight: 6 parts of humic acid, 5 parts of phosphorus pentoxide, 12 parts of potassium oxide, 0.05 part of sulfur element, 0.50 part of boron element, 0.01 part of zinc element, and 0.20 part of iron element , 0.1 part of molybdenum element, 1.00 part of magnesium element, 75.14 parts of amino acid hydrolyzate; the amino acid content in the amino acid hydrolyzate is 45%.

[0040] The preparation method of described amino acid micro-fertilizer comprises the following steps:

[0041] (1) Preparation of amino acid hydrolyzate: take discarded keratin from human body and animals, put the keratin into the ceramic tank, compact it, add 35% hydrochloric acid solution to fully soak; use water vapor above 100°C to Heat the outer vat of the pottery vat and react for 14 hours; adjust the pH value of the solution in the inner vat with sodium hydroxide to 5, filter to remove the filter residue, and t...

Embodiment 3

[0051] An amino acid micro-fertilizer, consisting of the following raw materials in parts by weight: 5 parts of humic acid, 6 parts of phosphorus pentoxide, 10 parts of potassium oxide, 1.00 parts of sulfur element, 0.20 part of boron element, 0.20 part of zinc element, and 0.10 part of iron element part, 0.30 part of molybdenum element, 0.50 part of magnesium element, and 76.7 parts of amino acid hydrolyzate; the content of amino acid in the described amino acid hydrolyzate is 40%.

[0052] The preparation method of described amino acid micro-fertilizer comprises the following steps:

[0053] (1) Preparation of amino acid hydrolyzate: take discarded keratin from human body and animals, put the keratin into the pottery tank, compact it, add 33% hydrochloric acid solution to fully soak; use water vapor above 100°C to Heat the outer cylinder and react for 12 hours; adjust the pH value of the solution in the inner cylinder with sodium hydroxide to about 6, filter to remove the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com