Y-shaped ring rubber material for automobiles and preparation method thereof

A technology for automobiles and rubber materials, which is applied in the field of automobile Y-ring rubber materials and its preparation. It can solve the problems of uneven dispersion of processing aids, unfavorable occupational safety of workers, poor tearing and oil resistance, etc., and achieve good mechanical properties and improve comprehensive performance. Performance, improve the effect of high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

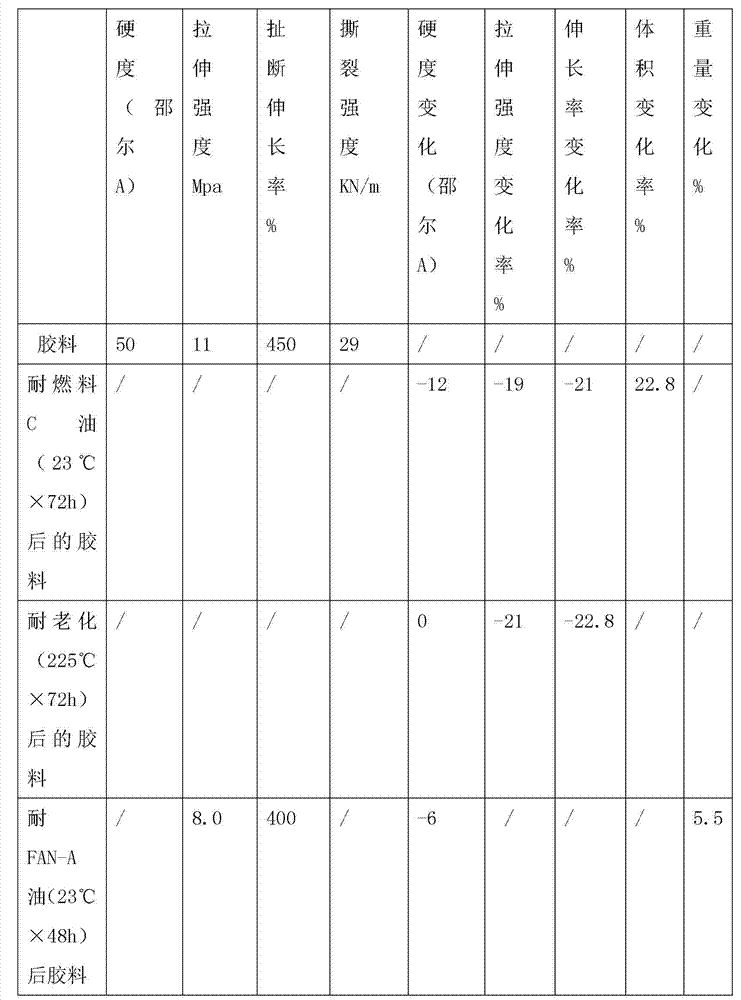

Examples

Embodiment Construction

[0020] A kind of preparation of automobile Y-shaped ring rubber compound,

[0021] Weigh 38kg of fluorosilicone rubber, 35kg of chlorohydrin rubber T3100, 18kg of chlorosulfonated polyethylene rubber TS-340 (Tosoh, Japan), 10kg of polyisobutylene, 14kg of modified tree ash, 2.5kg of ferrocene, diisopropyl peroxide Benzene DCP 0.4kg, fast extruded carbon black N660 37kg, fumed white carbon black 23kg, zinc oxide 5kg, dolomite 11kg, bauxite 11kg, modified iron tailings 15kg, accelerator CZ 0.2kg, accelerator DETU 0.3 kg, sodium stearate 1.5kg, antioxidant ODA 1.5kg, aminopropyltriethoxysilane 2kg, talcum powder 6kg,

[0022] The preparation method comprises the following steps:

[0023] (1) Preparation method of modified tree ash:

[0024] Add 5-6% of the weight of the tree ash to zinc borate and mix it, soak it with 15-20% hydrochloric acid for 1-2 hours, wash it with water until it is neutral, and after drying, add 0.5-1.0 % bis(dioctyloxypyrophosphate) ethylene titanate, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com