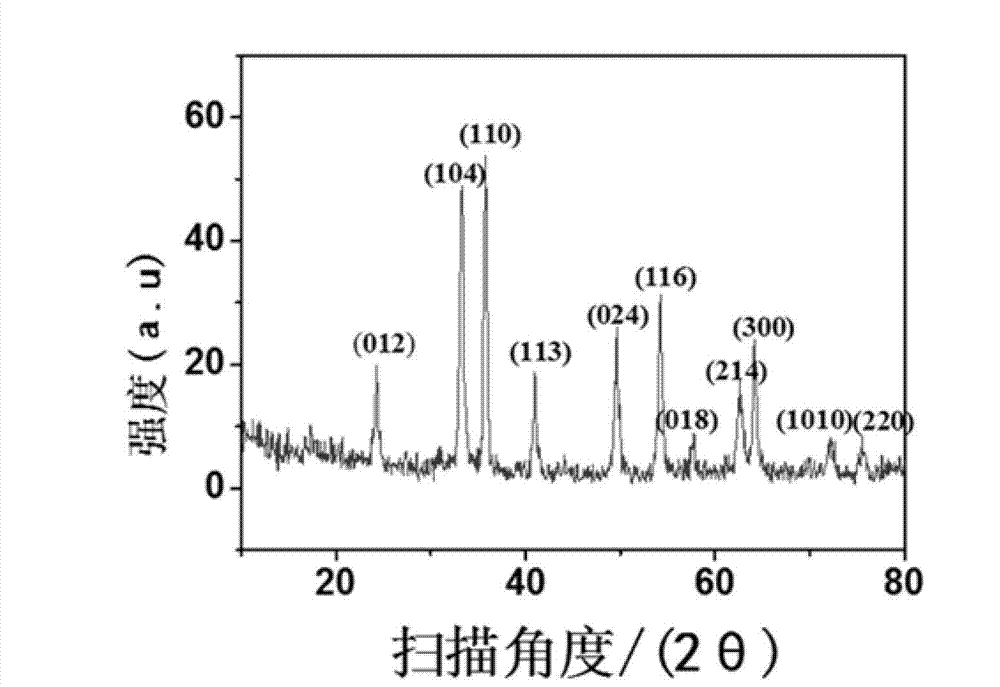

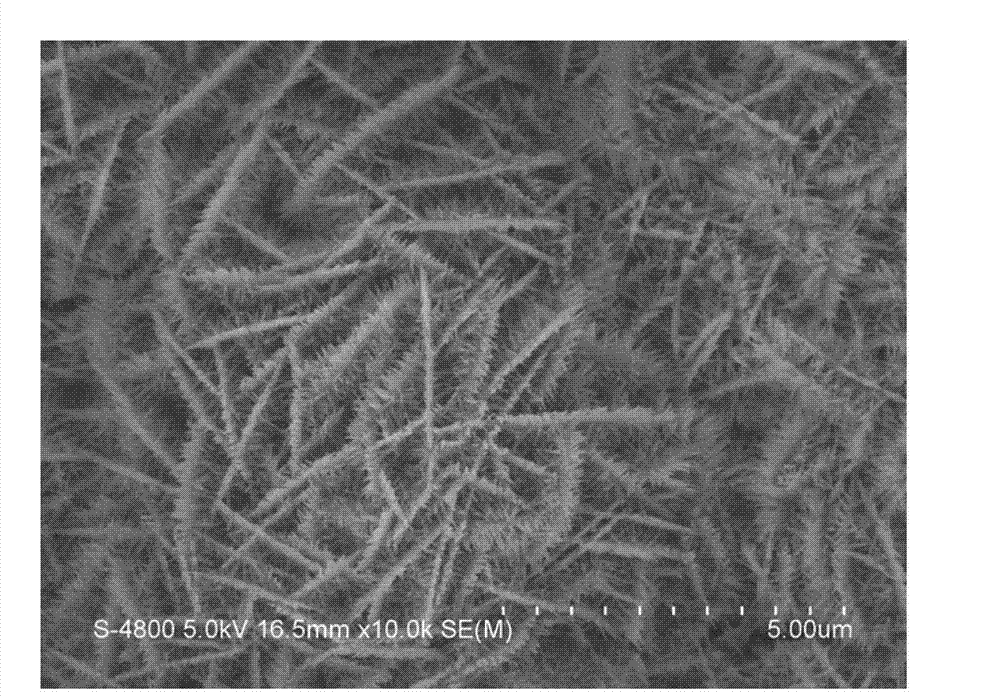

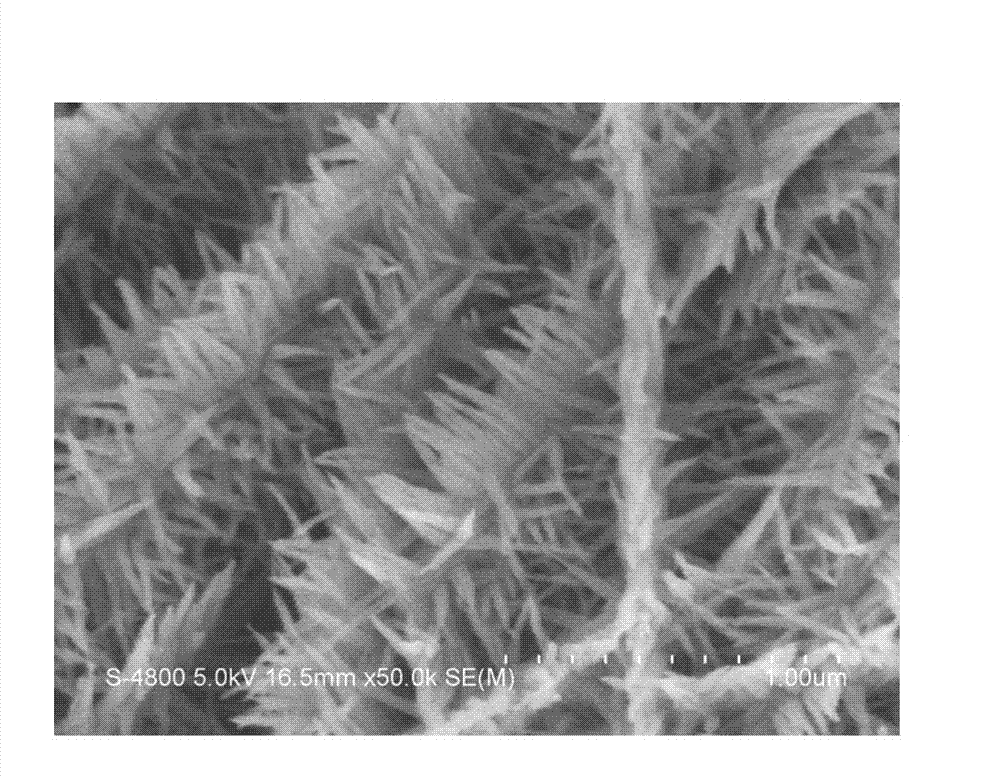

Preparation method of spatial network-like Fe2O3 composite material electrode

A composite material and space network technology, applied in the field of composite electrode preparation, can solve the problems of complex manufacturing process, small electricity storage capacity, complex preparation process, etc., and achieve the effects of low synthesis cost, large specific surface area and high reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In the ultrasonic cleaning machine, clean the iron sheet with anhydrous acetone, absolute ethanol, hydrochloric acid with a weight concentration of 36%-38%, distilled water, and absolute ethanol in sequence;

[0040] The thickness of the iron sheet is 1 cm, and the length is 4 cm.

[0041] Under room temperature and magnetic stirring conditions, mix 2 mL HCl (36%-38%) with 10 mL ethanol evenly, mix 10 mL oleic acid with 10 mL absolute ethanol, and mix the two solutions under magnetic stirring , to prepare a sol-gel acidic solution.

[0042] Transfer the prepared sol-gel acidic solution to a 60 mL reaction vessel, then, then transfer 1×4 cm 2 The treated iron sheet is cleaned and treated, and immersed in the above-mentioned sol-gel acidic solution, so that the area of the iron sheet exposed on the liquid surface is 1×1 cm 2 . Tighten the lid of the kettle, and react in an oven at 60°C for 6 hours. After the reaction, the kettle was taken out and cooled to room temp...

Embodiment 2

[0045] In the ultrasonic cleaning machine, clean the iron sheet with anhydrous acetone, absolute ethanol, hydrochloric acid with a weight concentration of 36%-38%, distilled water, and absolute ethanol in sequence;

[0046] The thickness of the iron sheet is 1 cm, and the length is 4 cm.

[0047]Under room temperature and magnetic stirring, mix 2 mL HCl (36%-38%) with 10 mL ethanol uniformly, mix 10 mL oleic acid with 10 mL absolute ethanol, and mix the two solutions under magnetic stirring , to prepare a sol-gel acidic solution.

[0048] Transfer the prepared sol-gel acidic solution to a 60 mL reaction vessel, then, then transfer 1×4 cm 2 The treated iron sheet has been cleaned and treated, and immersed in the above-mentioned sol-gel acidic solution, and the iron sheet exposed on the liquid surface is 1×1 cm 2 . Tighten the lid of the kettle, and react in an oven at 60° C. for 4 hours. After the reaction, the kettle was taken out and cooled to room temperature naturally, ...

Embodiment 3

[0051] The iron sheet processing steps are the same as in Example 1.

[0052] Under room temperature and magnetic stirring conditions, uniformly mix 2 mL HCl (36%-38%) with 10 mL ethanol, 10 mL oleic acid and 10 mL ethanol, and mix the two solutions under magnetic stirring to prepare A sol-gel acidic solution.

[0053] Transfer the prepared sol-gel acidic solution to a 60 mL reaction vessel, then, then transfer 1×4 cm 2 The treated iron sheet has been cleaned and treated, and immersed in the above-mentioned sol-gel acidic solution, and the iron sheet exposed on the liquid surface is 1×1 cm 2 . Tighten the lid of the kettle and react in an oven at 60°C for 2 hours. After the reaction is over, take out the kettle and cool it down to room temperature naturally, cover the iron sheet with a layer of red iron oxide, wash it with ethanol, and dry the iron sheet with iron oxide grown naturally to obtain an iron-iron oxide composite electrode, iron oxide Mass / area ratio with iron e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com