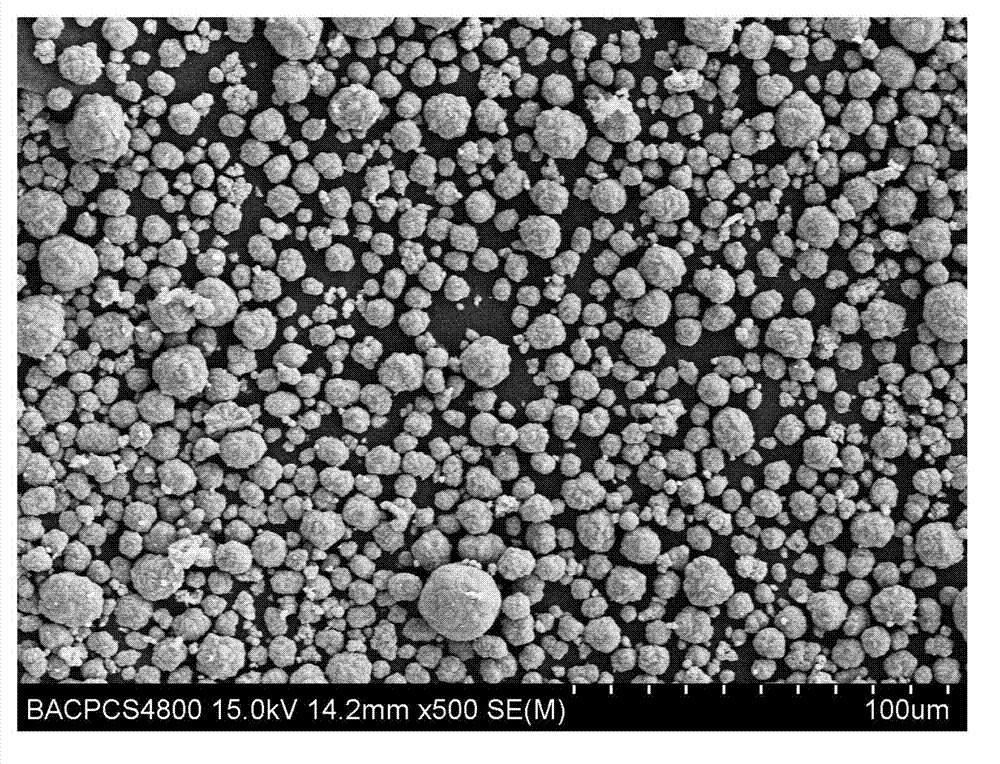

Preparation method of high-compaction spherical ternary cathode material

A positive electrode material, spherical technology, applied in the field of preparation of high vibration spherical ternary positive electrode material, can solve the problem of low packing density and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] NiSO 4 , MnSO 4 , CoSO 4 According to the molar ratio Ni: Mn: Co = 1: 1: 1, the mixed aqueous solution of nickel salt, manganese salt and cobalt salt is prepared, and the total concentration is 3.0 mol / L. In addition, 6.0 mol / L sodium hydroxide solution is prepared, and the metering pump is used to press Input the mixed salt solution of nickel, cobalt and manganese, sodium hydroxide solution and DMSO solution with a purity of 97% into the pre-filled 10cm 3 The reaction was carried out in a reactor with deionized water.

[0024] Under the protective condition of argon, the temperature of the reaction kettle is controlled to be 50°C, the flow rate of the alkali is controlled to make the pH value 11.0, the stirring speed is 500r / min, the solid content of the mother liquor is controlled to be 250mg / L, and the solid content of the liquid in the reaction kettle is controlled. The content is 450g / L, the feed liquid of the reactor is naturally discharged, the feed is continu...

Embodiment 2

[0027] Ni(NO 3 ) 2 , Mn(NO 3 ) 2 , Co(NO 3 ) 2 According to the molar ratio Ni:Mn:Co=4:4:2, prepare a mixed aqueous solution of nickel salt, manganese salt, cobalt salt, and the total concentration is 2.5mol / L. In addition, prepare a 5mol / L potassium hydroxide solution, and use a metering pump to measure Input nickel, cobalt, manganese mixed salt solution, potassium hydroxide solution and DMSO solution with a purity of 97% into the pre-filled 10cm 3 The reaction was carried out in a reactor with deionized water.

[0028] Under the condition of nitrogen protection, the temperature of the reaction kettle is controlled to be 60°C, the flow rate of the alkali is controlled so that the pH value is 10.5, the stirring speed is 600r / min, the solid content of the mother liquor is controlled to be 200mg / L, and the solid content of the feed liquid in the reaction kettle is controlled to be 400g / L, the reaction kettle feed liquid is discharged naturally, continuous feeding for 25 ho...

Embodiment 3

[0031] NiCl 2 , MnCl 2 , CoCl 2 According to the molar ratio Ni:Mn:Co=5:3:2, a mixed aqueous solution of nickel salt, manganese salt, and cobalt salt was prepared, with a total concentration of 2.5mol / L. In addition, a 5mol / L sodium hydroxide solution was prepared, and a metering pump was used to measure Input nickel, cobalt, manganese mixed salt solution, sodium hydroxide solution, and DMSO with a purity of 97% into the pre-filled 10m 3 The reaction was carried out in a reactor with deionized water.

[0032] Under the protection of helium, control the temperature of the reactor to 55°C, control the flow rate of the alkali to make the pH value 10.5, the stirring speed to 550r / min, control the solid content of the mother liquor to 260mg / L, and control the solid content of the liquid in the reactor 400g / L, the reaction kettle feed liquid is naturally discharged, continuous feeding for 35h, stop feeding, transfer the material in the reaction kettle to the aging tank, add 3mol / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com