Porous conductive additive and preparation method thereof, lithium ion battery

A porous conductive and additive technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reducing power density and energy density, heavy lithium-ion batteries, and increasing battery manufacturing costs, and achieves a reduced path, high Conductive efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing the above-mentioned porous conductive additive, in one embodiment, comprising the following steps:

[0032] (1) Disperse the graphene-based material in a solvent (preferably water) to obtain a dispersed solution of the graphene-based material, then add a pore-forming agent, the mass ratio of the pore-forming agent to the graphene-based material is 0.1-1000, ultrasonic or Obtain a uniform mixed solution after stirring;

[0033] (2) Heating the mixed solution obtained in step (1) for a period of time, the heating temperature is 40-100 ° C, and the time is 0.5-100 h, so that the pore-forming agent and the graphene-based material are fully mixed, and then the solvent (such as Evaporate to remove the solvent), dry the obtained solid (the mixture of graphene-based material and pore-forming agent), and heat it under an oxygen-free protective atmosphere (such as nitrogen or argon) for 0.5-20 h at a heating temperature o...

Embodiment 1

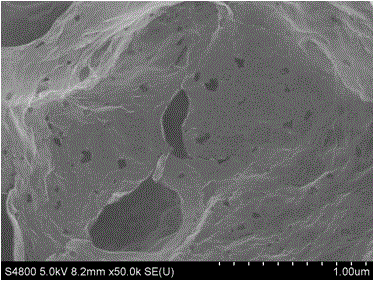

[0042] A conductive additive, which is a graphene oxide-based particle, the shape of the particle is flake, the size in the plane direction is 1-3μm, and the specific surface area is 1300m 2 / g, the size in the thickness direction is 0.5-5nm, the diameter of the through hole is 1-800nm, the porosity of the through hole is 25%, and the effective resistivity is 4.6 mΩ.cm. Its preparation method is as follows:

[0043] First 20g graphene oxide material is dispersed in water, obtains the dispersion solution of graphene oxide material; Add 20g Fe(NO 3 ) 3 , after the ultrasonic dispersion is uniform, add ammonia water to adjust the pH of the solution to 8, then add 50 g of citric acid, heat the above solution at 80 ° C for 40 h, and then evaporate to remove water, the obtained solid (pore-forming agent and reduced oxidation Graphene material mixture) was dried and heated under an argon atmosphere for 3 h at a heating temperature of 800 °C to obtain a conductive additive with ...

Embodiment 2

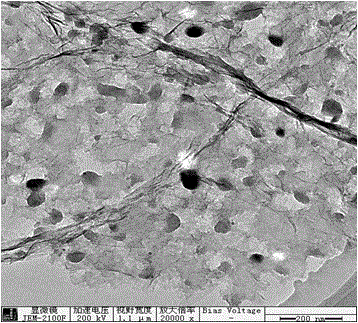

[0046] A conductive additive, which is a functionalized graphene-based particle modified with N-doping, the shape of the particle is flake-shaped, the size in the plane direction is 0.8-3 μm, and the specific surface area is 900m 2 / g, the size in the thickness direction is 0.2-3nm, the diameter of the through hole is 5-780nm, the porosity of the through hole is 35%, and the effective resistivity is 4.3 mΩ.cm. Its preparation method is as follows:

[0047] First, 1.8g of the functionalized graphene material modified with N doping is dispersed in water to obtain a dispersion solution of the functionalized graphene material modified with N doping; add 180g FeCl 3 , after mixing uniformly by ultrasonication for 1h, adding ammonia water to adjust the pH of the solution to 9, then adding 18g of vitamin C, heating the above solution at 85°C for 25h, and then evaporating to remove water, the obtained solid (pore-forming agent and reduction treatment) Graphene material mixture)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com