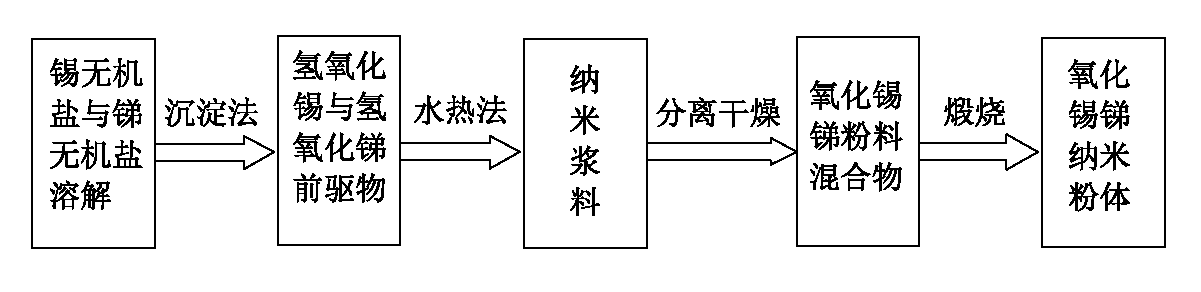

Preparation method of tin antimony oxide nano-powder

A technology of nano-powder and tin-antimony oxide, which is applied in the field of nano-materials, can solve the problems of danger, high cost, and low product purity, and achieve the effects of reducing equipment requirements, narrow particle size distribution, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step (1) Step: Solubbines tin nitrate and nitrate in dilute hydrochloric acid with a concentration of 3%and concentration of 36%, respectively, and then transferred to the enamel reaction kettle. Slowly add sodium hydroxide under the condition of mechanical stirring conditions.Until the pH value reaches 10, it continues to stir until tin ions and ions are completely precipitated to obtain hydroxide and hydroxide precursors.

[0034] Step (2): Filtering is separated and used to wash the hydrogen oxide and hydroxide precursor before the ion water, until the soluble substance is completely removed.

[0035] Step (3): Add 2 times water to the precursor after washing in step (2).The amount of sodium sodium sodium sodium is 5%of the total weight of the hydroxide and hydroxide precursor and water. After stirring evenly, transfer it to the water heat reactor.

[0036] Step (4): The temperature in the water heating reaction kettle is 250 ° C, and continuously reacts for 1h in a cont...

Embodiment 2

[0041] Step (1): The tin tin chloride and trichloric chloride are dissolved in dilute hydrochloric acid with a concentration of 10%and a concentration of 32%.Add ammonia until the pH value reaches 9 and continues to stir until tin ions and ions are completely precipitated to obtain hydroxide and hydroxide precursor.

[0042] Step (2): Filtering is separated and used to wash the hydrogen oxide and hydroxide precursor before the ion water, until the soluble substance is completely removed.

[0043] Step (3): Add 3 times water to the precursor after washing in step (2).The addition of sodium viralnzenezine is 3%of the total weight of the hydroxide and hydroxide precursor and water. After stirring, mix it to the water thermal reactor.

[0044] Step (4): The temperature in the water heating reaction kettle is 220 ° C, and the reaction is continuously reacted for 2h in the stirring state to make nanoplogen.

[0045] Step (5) step: After separation and drying, it is a mixture of tin oxid...

Embodiment 3

[0049] Step (1) Step: Solubbines tin nitrate and trichlot chloride in dilute hydrochloric acid with a concentration of 15%and a concentration of 30%, and then transferred to the enamel reaction kettle, slowly add hydrogen under the condition of mechanical stirring.Until the pH value reaches 8, it continues to stir until tin ions and ions are completely precipitated to obtain hydroxide and hydroxide precursor.

[0050] Step (2): Filtering is separated and used to wash the hydrogen oxide and hydroxide precursor before the ion water, until the soluble substance is completely removed.

[0051] Step (3): Add 4 times water to the forefront of the front drive to the front -drive (2) step (2).The amount is 0.5%of the total weight of the hydroxide and hydroxide precursor and water, and then mounted to the water thermal reactor after stirring.

[0052] Step (4): Control the temperature in the water heating reaction kettle to 200 ° C, continuously reacts for 3h in a continuous reaction in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com