Sunscreen composition and preparation method thereof

A technology of composition and weight, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve the problems of skin phototoxicity, sunscreen photoinstability, and limitations of sunscreen functions, so as to improve durability and safety Sexuality, long-lasting sun protection ability, and good photostability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

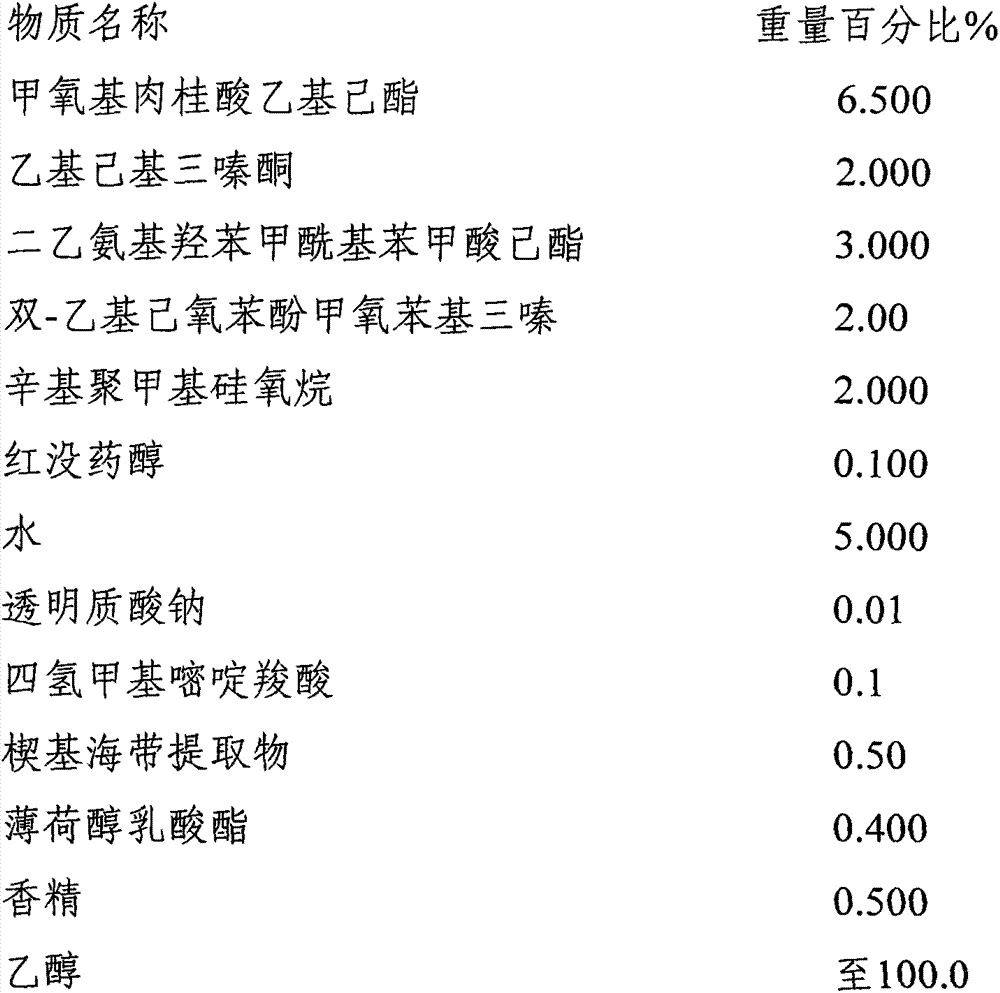

[0052] The preparation of embodiment 1 sunscreen spray

[0053] formula:

[0054]

[0055] Process:

[0056] Put ethylhexyl methoxycinnamate, ethylhexyl triazone, diethylamino hydroxybenzoyl hexyl benzoate, bis-ethylhexyloxyphenol methoxyphenyl triazine in a container and heat to 80°C, stir to dissolve, add octyl polymethicone, menthol lactate, stir to dissolve, cool to 30°C, add kelp extract, stir to dissolve. Ethanol was added to the above mixture, stirred to dissolve, and solution 1 was obtained. Hyaluronic acid and tetrahydromethylpyrimidinecarboxylic acid were added to purified water, stirred to prepare an aqueous solution, and added to solution 1 to obtain solution 2. Add bisabolol and essence to solution 2, stir to dissolve, then fill in a high-pressure container, inject propellant (isobutane gas), and obtain the spray of the present invention.

Embodiment 2

[0057] The preparation of embodiment 2 emulsion

[0058] formula:

[0059]

[0060] Process:

[0061] Preparation of oil phase: put ethylhexyl methoxycinnamate, ethylhexyl triazone, diethylamino hydroxybenzoyl hexyl benzoate, bis-ethylhexyloxyphenol methoxyphenyl triazine in a container In the medium, heat to 80°C, stir to dissolve, add polysorbate-60, stir to dissolve, cool to 20°C, add kelp extract, stir to dissolve, add acrylic acid (ester) / C10-30 alkane Alcohol acrylate cross-linked polymer, stir to disperse evenly to obtain oil phase.

[0062] Water phase preparation: add glycerin, disodium EDTA, arginine, sodium hyaluronate, tetrahydromethylpyrimidine carboxylic acid, and methylisothiazolinone into purified water in sequence, and stir to dissolve to obtain an aqueous phase.

[0063] Add the oil phase to the water phase and homogenize at 3000rpm for 20 minutes. Then ammonium acryloyldimethyltaurate / VP copolymer was added and homogenization was continued for 20 minu...

Embodiment 3

[0064] The preparation of embodiment 3 refreshing cleansing emulsion

[0065] formula:

[0066]

[0067]

[0068] Process:

[0069] 1. Water phase: Add purified water, glycerin, 1,3-butanediol, EDTA-2Na, and potassium hydroxide into the container, stir and mix evenly, heat to 80°C, and set aside.

[0070] 2. Oil phase: Add lauric acid, myristic acid, palmitic acid, stearic acid, and ethylene glycol distearate into the container, stir and mix evenly, heat to 80°C, and set aside.

[0071] 3. Mix the water phase and the oil phase, homogenize at 3000rpm for 10 minutes, then stop the homogenization, keep stirring for 60 minutes, then cool down to 40°C, add ethylhexyl methoxycinnamate, ethylhexyl triazone , diethylamino hydroxybenzoyl hexyl benzoate, bis-ethylhexyloxyphenol methoxyphenyl triazine, methylisothiazolinone, fragrance, tetrahydromethyl pyrimidine carboxylic acid, kelp extract, Continue to stir and cool down to 32°C to obtain the facial cleanser of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com