Nano-loading zero-valent-iron-based PVDF (Polyvinylidene Fluoride) compound material as well as preparation method and application thereof

A composite material and nano-zero-valent technology, applied in the field of water treatment, can solve the problems of easy aggregation of particles, unsatisfactory catalytic degradation ability, easy loss and clogging of particles, and achieve good dispersion, enhanced reusability, and easy recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

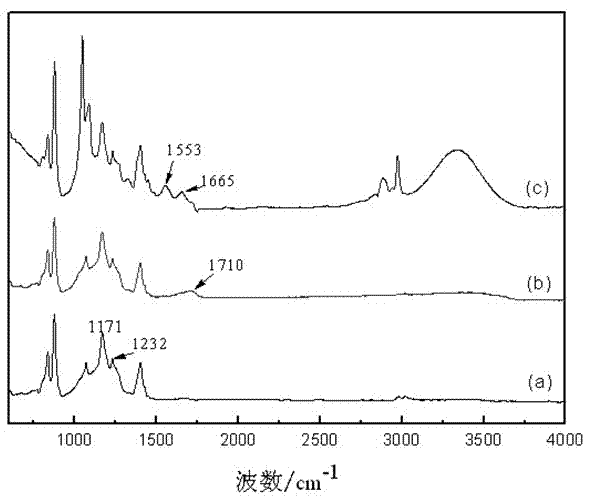

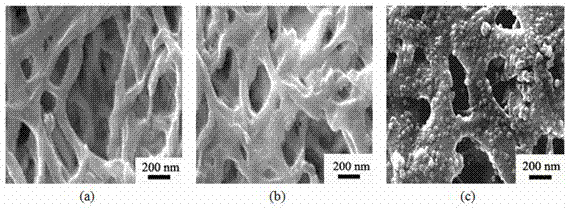

[0059] Embodiment 1: the preparation method of nanometer zero-valent iron-based PVDF composite material and the experiment of removing nitrate ions in water, the specific contents are as follows:

[0060] (1) First take a piece of PVDF microporous filter membrane and soak it in a clean beaker filled with absolute ethanol for 1 hour, then transfer it to a clean beaker filled with deionized water and soak for 48 hours, and replace the deionized water every 12 hours ; This step is to remove impurities in the PVDF microporous membrane, and make the membrane reach shrinkage balance, and also create corresponding conditions for the functionalization of the subsequent membrane to complete the pretreatment of the membrane;

[0061] (2) Prepare AA functional solution (a mixed aqueous solution containing 30 wt% AA, 2 wt% ethylene glycol and 1 wt% potassium persulfate), and then immerse the pretreated PVDF filter membrane in the above functional solution, After 4 min, the filter membrane...

Embodiment 2

[0069] Embodiment 2: the preparation method of nanometer zero-valent iron-based PVDF composite material and the experiment of removing methyl orange in water, the specific contents are as follows:

[0070] (1) First take a piece of PVDF microporous filter membrane and soak it in a clean beaker filled with absolute ethanol for 0.5 h, then transfer it to a clean beaker filled with deionized water for 36 h, and replace the deionized water every 12 h ;

[0071] (2) Prepare AA functional solution (a mixed aqueous solution containing 10wt% AA, 1 wt% ethylene glycol and 0.5 wt% potassium persulfate), and then immerse the pretreated PVDF filter membrane in the above functional solution, and take it out after 3 min filter membrane, and send the filter membrane to a vacuum drying oven at 90 °C for drying, then soak the functionalized PVDF filter membrane in deionized water for 36 h, and replace the deionized water every 12 h to remove excess components attached to the surface , this st...

Embodiment 3

[0078] Embodiment 3: the preparation method of nano zero-valent iron-based PVDF composite material and its removal of Cu in water 2+ Ion experiment, the specific content is as follows:

[0079] (1) First take a piece of PVDF microporous filter membrane and soak it in a clean beaker filled with absolute ethanol for 4 hours, then transfer it to a clean beaker filled with deionized water and soak for 72 hours, and replace the deionized water every 12 hours ;

[0080] (2) Prepare the AA functional solution (a mixed aqueous solution containing 50 wt% AA, 10 wt% ethylene glycol and 2 wt% potassium persulfate), and then immerse the pretreated PVDF filter membrane in the above functional solution, after 5 min Take out the filter membrane, and send the filter membrane to a vacuum drying oven at 120 °C for drying, then soak the functionalized PVDF filter membrane in deionized water for 72 h, and replace the deionized water every 12 h to remove excess particles attached to the surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com