Fluoropolymer microsphere

一种聚合物、微球的技术,应用在运输和包装、涂层、薄料处理等方向,能够解决反应压力高、反应过程制约二氧化碳流体等问题,达到保证稳定性、降低压力、缩短时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This example describes a synthetic example of the stabilizing dispersant employed in this invention. Azobisisobutyronitrile (AIBN) thermal initiator (0.04g, 0.00025mol), BPTTC (0.24g, 0.0010mol) and two polymerized monomers in different proportions (15.3g in total, see Table 1 for the charging ratio) were dissolved In 10 ml of trifluorotoluene, under nitrogen atmosphere, heated to 60 °C, and random copolymerization was carried out for 48 hours. The polymer was precipitated from solution with methanol and filtered and dried in a vacuum oven at 45°C for 24 hours.

[0041] Table 1 Monomer composition ratio and number average molecular weight of random copolymers (M n )

[0042]

[0043]

[0044] In Table 1, in the second monomer, BA refers to butyl acrylate, DMAEMA refers to dimethylaminoethyl methacrylate; the first monomer is dodecafluoroheptyl methacrylate (HFPMA); the monomer charging ratio refers to is the weight ratio of the first monomer and the second mono...

Embodiment 2

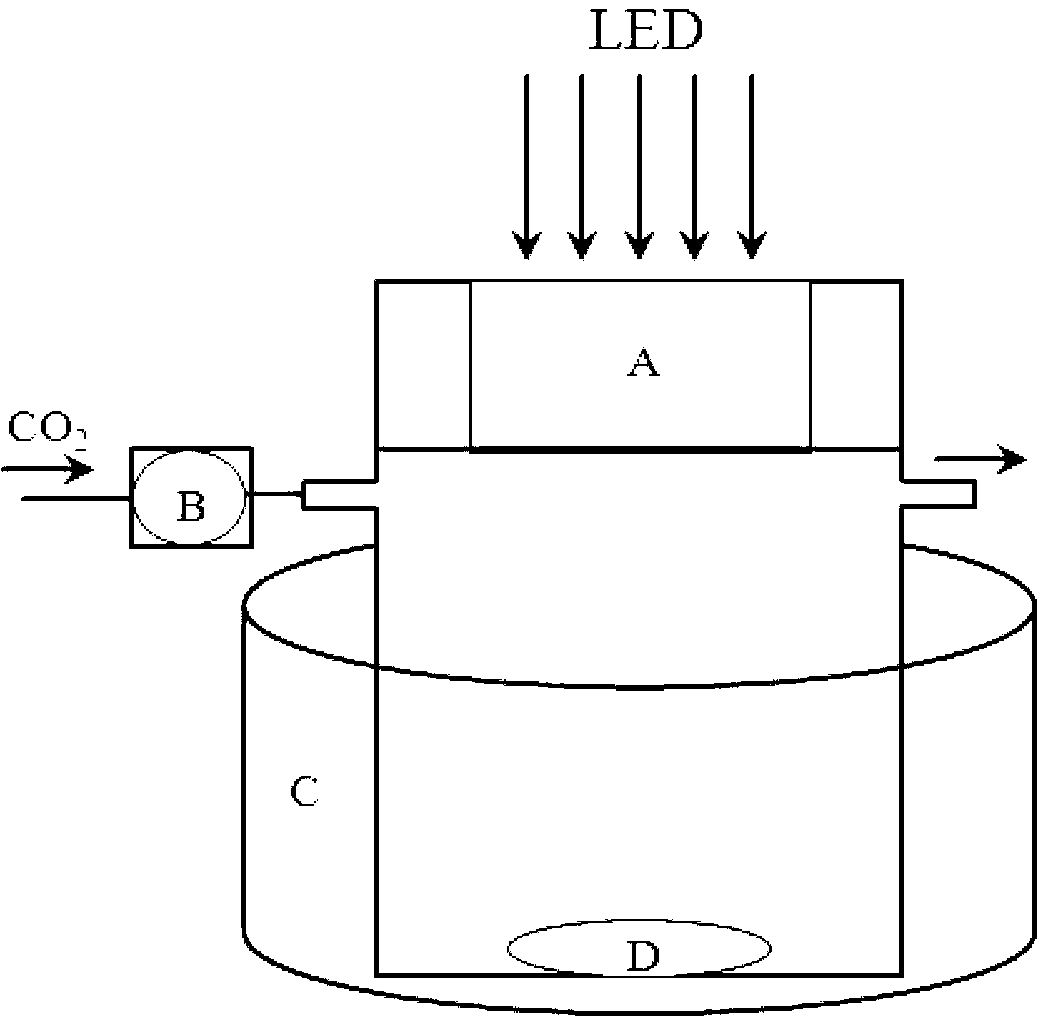

[0047] The fluoropolymer microspheres of this example were prepared by the following steps: photoinitiated dispersion polymerization in a 40ml autoclave (such as figure 1 shown), the quartz glass above the autoclave was used as the light transmission window, and a 3W LED (wavelength range: 405-410 nm) was used as the light source. The reactor was placed in an ice-water bath with a magnetic stirrer below. The polymerized monomer isobornyl acrylate (IBOA), the photoinitiator 2,4,6-trimethylbenzoyldiphenylphosphine oxide (TPO) and the stabilized dispersant S-DM-1 were added to the reactor respectively. . The concentration of the polymerized monomer IBOA in the total volume of the polymerized monomer and liquid carbon dioxide is 0.10g / ml, the amount of the photoinitiator TPO is 2.0wt% of the polymerized monomer, and the amount of the stabilized dispersant S-DM-1 is the polymerized monomer. 7wt% of the body. A small amount of carbon dioxide gas was introduced, and then slowly di...

Embodiment 3

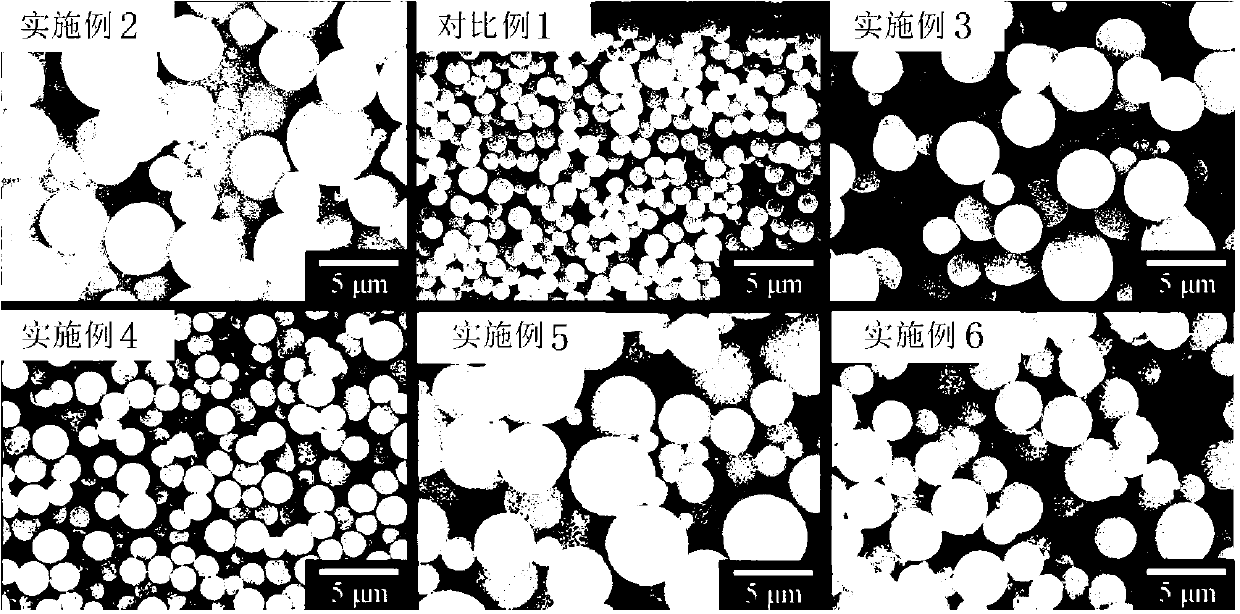

[0051] In this example, the stable dispersant S-DM-2 is used instead of S-DM-1 in the example, and the types and amounts of other reagents and the implementation process are the same as those in Example 2. Scanning Electron Microscopy (SEM) of the resulting product is shown in figure 2 ,Depend on figure 2 It can be seen that the obtained polymer product is a regular spherical shape, there is no obvious adhesion between the microspheres, and the particle size of the microspheres is basically 1-10 microns, which is suitable as an additive for coating products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| surface free energy | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com