Settleability water base grinding fluid and preparation method thereof

A grinding liquid and sedimentation technology, which is applied in the field of grinding liquid, can solve the problems such as palliatives but not the root cause, and achieve the effects of prolonging the life of the grinding wheel, excellent antibacterial and bactericidal effects, and beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

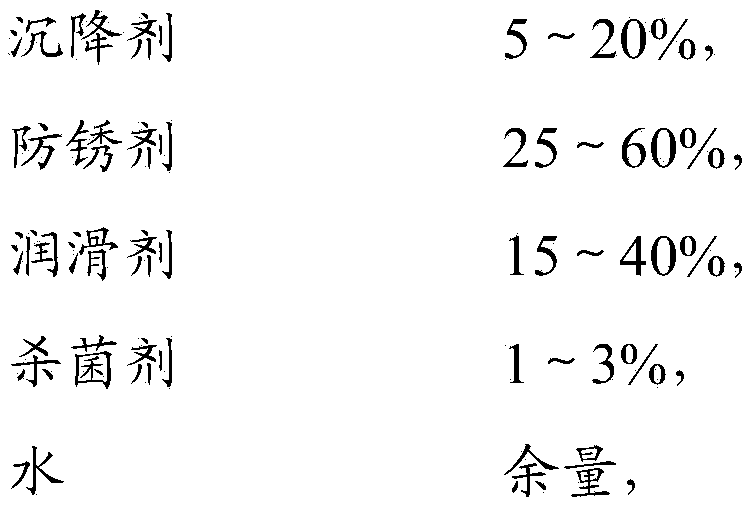

[0060] A kind of sedimentation water-based grinding liquid, the mass percent of each component is as follows:

[0061] Polydichloroethyl ether tetramethylethylenediamine 1%,

[0062] Polyglycerin 8%,

[0063] Ethylene glycol monobutyl ether 2%,

[0064] 2,4,6-tris(aminocaproyl)-1,3,5-triazine 3%,

[0065]Monoethanolamine 8%,

[0066] Triethanolamine 12%,

[0067] Undecanedioic Acid 3%,

[0068] Dodecanedioic Acid 3%,

[0069] Benzoic acid 2%,

[0070] Tolylbenzotriazole 0.5%,

[0071] Potassium Hydroxide 2.5%,

[0072] Potassium Tetraborate 6%,

[0073] Isomerized alcohol ethoxylates 7%,

[0074] Glycerol 9%,

[0075] Methylisoquinolinone 0.5%,

[0076] Water 32%.

Embodiment 2

[0078] A kind of sedimentation water-based grinding liquid, is made up of each component of following mass percentage:

[0079] Polydichloroethyl ether tetramethylethylenediamine 1%,

[0080] Polyglycerin 8%,

[0081] Ethylene glycol monobutyl ether 2%,

[0082] Nitrogen-containing heterocyclic tricarboxylic acid 3%,

[0083] Monoethanolamine 8%,

[0084] Triethanolamine 12%,

[0085] Undecanedioic Acid 4%,

[0086] Dodecanedioic Acid 2%,

[0087] Benzoic acid 2%,

[0088] Tolylbenzotriazole 0.5%,

[0089] Potassium Hydroxide 2.5%,

[0090] Potassium Tetraborate 6%,

[0091] Isomerized alcohol ethoxylates 6%,

[0092] Glycerol 8%,

[0093] Methylisoquinolinone 0.5%,

[0094] Iodopropynyl carbamate 0.5%,

[0095] Water 32%.

Embodiment 3

[0097] A kind of sedimentation water-based grinding liquid, is made up of each component of following mass percentage:

[0098] Polydichloroethyl ether tetramethylethylenediamine 1%,

[0099] Polyglycerin 10%,

[0100] Ethylene glycol monobutyl ether 2%,

[0101] Nitrogen-containing heterocyclic tricarboxylic acid 3%,

[0102] Monoethanolamine 6%,

[0103] Triethanolamine 16%,

[0104] Undecanedioic Acid 3%,

[0105] Dodecanedioic Acid 3%,

[0106] Benzoic acid 2%,

[0107] Tolylbenzotriazole 0.5%,

[0108] Potassium Hydroxide 2.5%,

[0109] Potassium Tetraborate 6%,

[0110] Isomerized alcohol ethoxylates 4%,

[0111] Glycerol 8%,

[0112] Methylisoquinolinone 0.5%,

[0113] 1-Hydroxy-2(1H)-pyridinethione sodium 0.5%,

[0114] Water 32%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com