Production method and products of flexible cable for wind power generation

A manufacturing method and technology for flexible cables, which are applied in cable/conductor manufacturing, insulated cables, flexible cables, etc., can solve problems such as unfavorable environmental protection workers' health, high production risks, and changing insulation structures, etc., and achieve vertical improvement. Load bearing performance, effect of reducing dead weight and outer diameter, reducing sheath thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

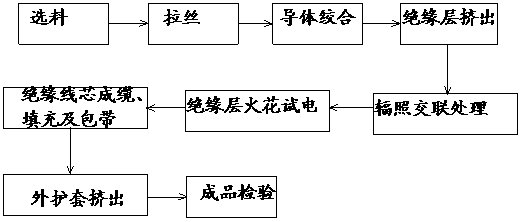

[0039] like figure 1 Shown, a kind of manufacturing method of flexible cable for wind power generation, comprises the steps:

[0040] (1) Material selection: T1-type Φ8mm electrical round copper rod is selected as the conductor material, which complies with the GB / T3952 standard.

[0041] (2) Wire drawing: The conductor material is drawn and annealed to obtain a soft round copper wire that meets the required diameter. The copper wire meets the requirements of the fifth type of conductor specified in GB / T3956. The conductor can be tinned or not tinned.

[0042](3) Conductor stranding: the soft round copper wire obtained in step (2) is twisted at a twisting pitch no greater than 20 times to obtain a bundle of strands...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com