Method for extracting saikosaponin from bupleurum chinense by using two-level foam separation process

A foam separation method and foam separation technology, which is applied in the field of extraction and separation of total saponins of Bupleurum, can solve the problems of resin regeneration, large consumption of organic reagents, poor separation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The first step, preparation and detection of saikosaponin crude extract

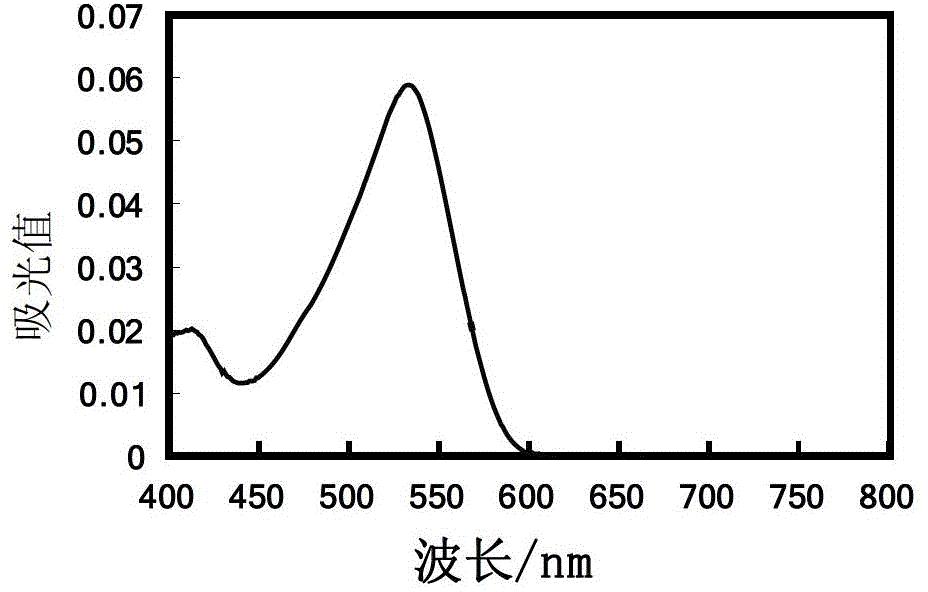

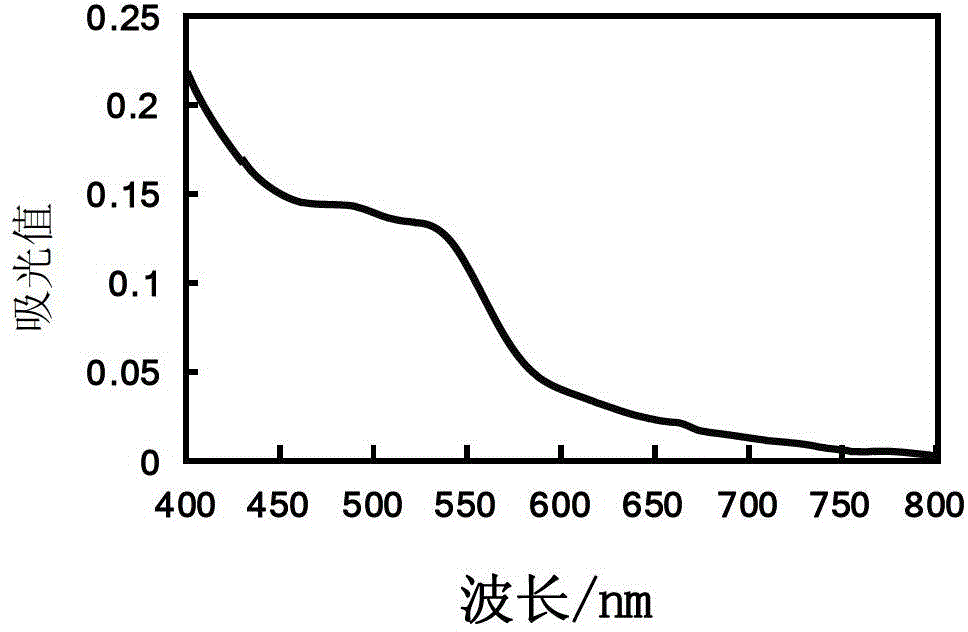

[0029] Dry and pulverize 100g Bupleurum decoction pieces, pass through a 40-mesh sieve, cold soak and extract with ethanol with a pH of 9 and a concentration of 60% for 12 hours, and the ratio of solid to liquid is 1:7; filter, and extract twice by cold soak according to this process, and combine About 1.4L of the extract was stored in a refrigerator at 4°C; the concentration of the saikosaponin crude extract was 0.08-0.32 mg / ml, and the determination method was p-dimethylaminobenzaldehyde-hydrochloric acid colorimetric method.

[0030] The second step, Bupleurum crude extract pretreatment

[0031] The ethanol in the stock solution was recovered under reduced pressure to a volume of 200ml, and diluted to 2L with water to obtain a crude saikosaponin extract. The measured total saponin concentration of Bupleurum is 0.15mg / ml, the pH value is adjusted to 10, and the obtained saponin aqueous solution...

Embodiment 2

[0039] The first step, the preparation and detection of saikosaponin crude extract;

[0040] Dry and crush 70g Bupleurum decoction pieces, pass through a 40-mesh sieve, and extract with deionized water adjusted to pH 9 with sodium hydroxide for 12 hours by cold immersion method, the ratio of solid to liquid is 1:5; filter, and extract by cold immersion according to this process 2 times, the combined extracts were stored in a refrigerator at 4°C.

[0041]The second step, Bupleurum crude extract pretreatment

[0042] Take out the stock solution and add water to quantify it to 1L to obtain the saikosaponin crude extract. The measured total saikosaponin concentration is 0.18 mg / ml, adjust the pH value to 9, and use the obtained saponin aqueous solution as the initial feed liquid to enter the secondary foam The first stage foam separation tower in the separation process.

[0043] The third step, the first stage foam separation process

[0044] The temperature of the first-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com