Hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst and catalyst technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of reducing the dispersion of active components and reducing the utilization of active metals , Difficult vulcanization of active components and other problems, to achieve the effect of increasing loading capacity and high dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

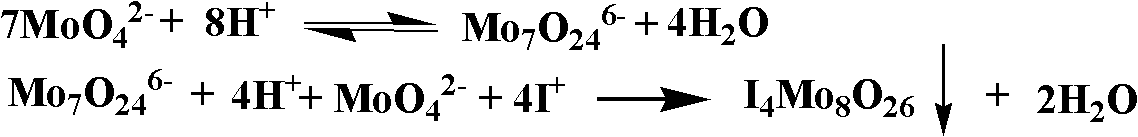

[0029] A preparation method of a hydrogenation catalyst, the carrier of the hydrogenation catalyst is loaded with VIB group and VIII group metal active components, and the preparation method comprises:

[0030] (1) Prepare a salt solution containing VIB group metals, acidify it by adding mineral acid, and adjust its pH value to 1-7;

[0031] (2) Prepare the organic quaternary ammonium salt solution, and add the organic quaternary ammonium salt solution dropwise at a speed of 1ml / min to 5ml / min in the salt solution containing VIB group metals in the process of constant stirring to form a suspension , continue stirring for 0 minutes to 120 minutes;

[0032] (3) Transfer the suspension to an autoclave filled with a carrier, and then place the autoclave in a rotary oven to allow the particles in the suspension to diffuse and deposit in the pores of the carrier at 50°C to 150°C 1. Aging for 10 hours to 30 hours; after the aging, the suspension is filtered, washed with water, dried...

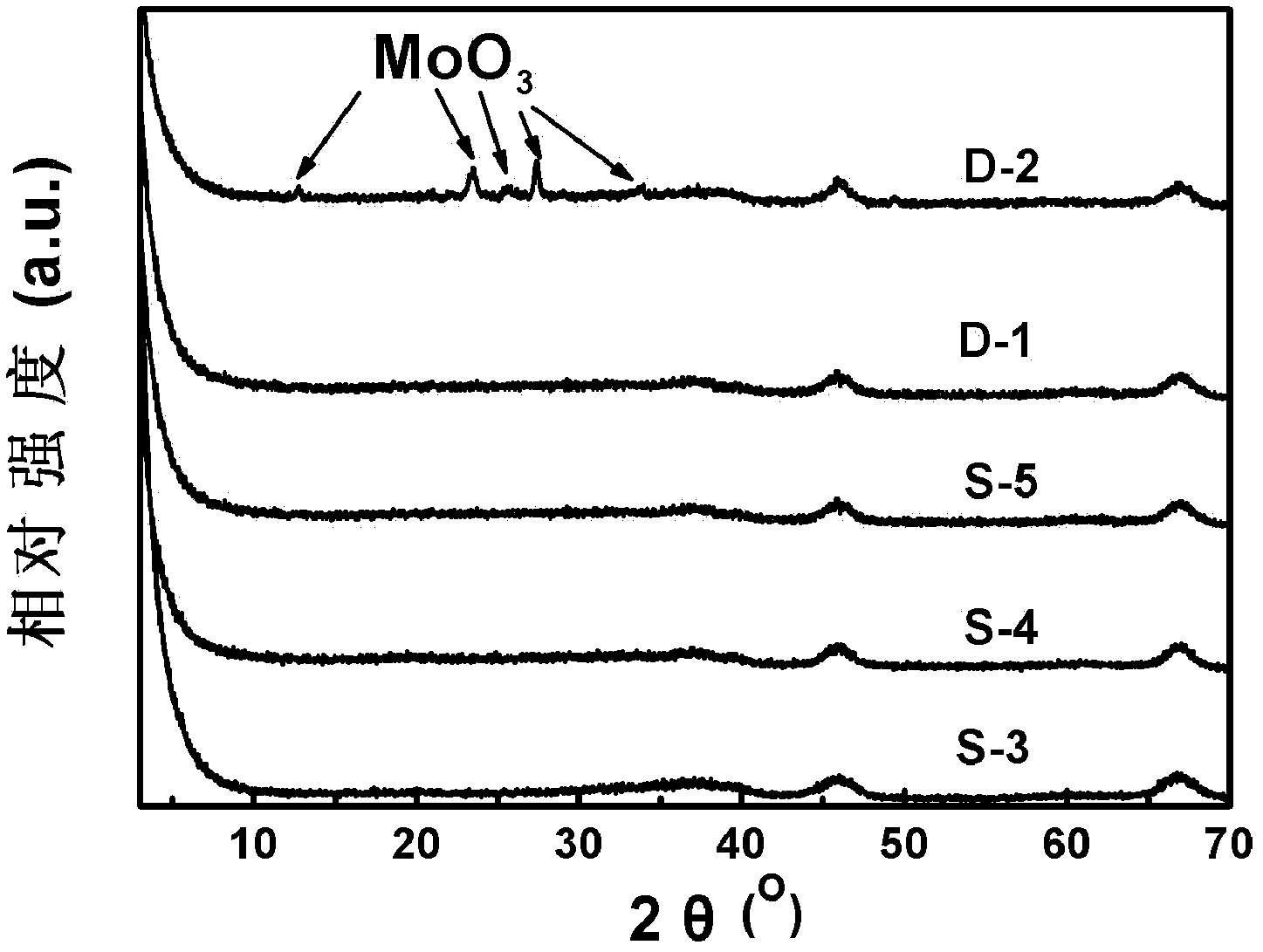

Embodiment 1

[0049] Prepare 40mL of 0.15mol / L sodium molybdate solution, add 3.0mL of 2.4mol / L hydrochloric acid dropwise during stirring to obtain solution A; then prepare 20mL containing 0.792g dodecyltrimethylammonium chloride (DTAC) Solution B (mol MoO 4 2- :DTAC=1:0.5), in the process of constant stirring, solution B was added dropwise to solution A at a speed of 1mL / min to form a suspension, and the stirring was continued for 30min; then the suspension was transferred to a container containing 2.04g γ-Al with a diameter of 2-5mm 2 o 3 Then place the autoclave in a rotary oven to diffuse, deposit, and age the precipitated particles at 120°C for 12 hours. After the aging, the suspension is filtered, washed with water, dried at 120°C for 10 hours, and then dried at 500°C. Calcined for 4h to get Mo / Al 2 o 3 . Then prepare a nickel nitrate solution containing 5.3 g of nickel nitrate and about 15 mL, and add 1.5 mL of it to Mo / Al 2 o 3 It was soaked in the medium, placed at room te...

Embodiment 2

[0051] Prepare the sodium molybdate solution of 40mL 0.15mol / L, in stirring process, dropwise add 3.5mL of 2.4mol / L hydrochloric acid, obtain solution A; Then prepare 20mL solution B containing 0.792g DTAC (mol MoO 4 2- :DTAC=1:0.5), in the process of constant stirring, solution B was added dropwise to solution A at a speed of 3mL / min to form a suspension, and continued to stir for 30min; then the suspension was transferred to a container containing 2.04g γ-Al with a diameter of 2-5mm 2 o 3Then place the autoclave in a rotary oven to diffuse, deposit, and age the precipitated particles at 120°C for 12 hours. After the aging, the suspension is filtered, washed with water, dried at 120°C for 10 hours, and then dried at 500°C. Calcined for 4h to get Mo / Al 2 o 3 . Then prepare a nickel nitrate solution containing 5.8g of nickel nitrate and about 15mL, and add 1.5mL of it to the Mo / Al 2 o 3 Let it be soaked in the medium, let it stand at room temperature for 12h, then dry at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com