Flue gas denitrification catalyst on-line regeneration cleaning liquid and preparation method thereof

A technology for denitration catalyst and cleaning solution, which is applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc. Small medium consumption, improved catalytic activity, and recovery of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of regeneration solution: sulfuric acid accounting for 1wt.% of the total amount; alkali-resistant penetrating agent OEP-70 accounting for 0.1wt.% of the total amount; surfactant ammonium lauryl sulfate CH accounting for 0.1wt.% of the total amount 3 (CH 2 ) 11 OSO 3 NH 4 ; The rest is deionized water.

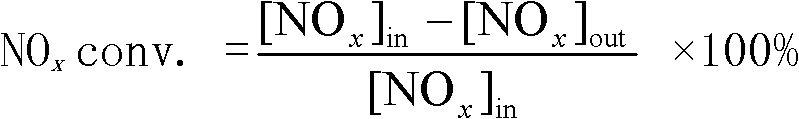

[0035] 2. Take a Ti-V-W honeycomb catalyst sample (150*150*1000mm) that has been running for 20,000 hours, and the denitrification rate has dropped from 92% to 44% (after sampling test) on the self-built online dynamic simulation test bench Clean up. The self-built online dynamic simulation test bench is a system established according to Chinese patent application 201110391919.4, an online regeneration system and method for flue gas denitrification catalysts. It consists of a simulated flue system, a simulated flue system, and connecting pipes. The medium storage or generating part, the regenerative medium heating part and the regenerative medium con...

Embodiment 2

[0043] 1. Preparation of regeneration solution: oxalic acid accounting for 1wt.% of the total amount; alkali-resistant penetrant AEP accounting for 0.5wt.% of the total amount; surfactant aliphatic amine (alkylamine) polyoxide accounting for 0.5wt.% of the total amount vinyl ether; the remainder was deionized water.

[0044] 2. Take a Ti-V-W series honeycomb catalyst sample (150*150*1000mm) that has been in operation for 20,000 hours, and the denitrification rate has dropped from 92% to 44% (after sampling test) on the self-built online dynamic simulation test bench ( Clean up with embodiment 1). Flow rate of cleaning fluid: 20m 3 / h (to ensure the flow rate of cleaning liquid entering the catalyst layer in the cleaning area, so that the upper surface of the catalyst layer is submerged, and keep the balance between the perfusion volume and its free fall volume, so that the volume of the treated catalyst layer is completely filled with liquid), pressure: atmospheric pressure ...

Embodiment 3

[0047] 1. Preparation of regeneration solution: citric acid accounting for 1wt.% of the total; high-temperature penetrant JFC-M accounting for 1wt.% of the total; surfactant OE-35 accounting for 1wt.% of the total; the rest is deionized water .

[0048] 2. Take a Ti-V-W series honeycomb catalyst sample (150*150*1000mm) that has been in operation for 20,000 hours, and the denitrification rate has dropped from 92% to 44% (after sampling test) on the self-built online dynamic simulation test bench ( Clean up with embodiment 1). Flow rate of cleaning fluid: 20m 3 / h (to ensure the flow rate of cleaning liquid entering the catalyst layer in the cleaning area, so that the upper surface of the catalyst layer is submerged, and keep the balance between the perfusion volume and its free fall volume, so that the volume of the treated catalyst layer is completely filled with liquid), pressure: atmospheric pressure , temperature: 60°C, time: 30min.

[0049] 3. The sample was tested afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com