N-octadecane phase change micro-emulsion as well as preparation method and application thereof

A technology of phase change microemulsion and n-octadecane, which is applied in the field of microemulsion and its preparation, can solve the problems of low fluid center temperature, high fluid viscosity, stratification, etc., and achieve a wide applicable temperature range, simple and broad preparation method The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of n-octadecane phase change microemulsion of the present invention, described phase change microemulsion is made up of the component of following mass fraction:

[0026] n-octadecane 5%~40%,

[0027] Surfactant 2%~20%,

[0028] Fatty alcohols 1% to 10%,

[0029] Inorganic salts 0.25% to 3% and

[0030] remaining water.

[0031] The above-mentioned surfactants are preferably one or more compounded surfactants with a hydrophilic-lipophilic balance value (HLB value) greater than or equal to 8.

[0032] In the above-mentioned n-octadecane phase-change microemulsion, the surfactant is an industrial grade agent, specifically Tween80, Tween60, Tween40, Tween20, fatty alcohol polyoxyethylene ether, alkylphenol polyoxyethylene ether, dodecane Sodium sulfate, sodium dodecylbenzenesulfonate, Turkish red oil, polyoxyethylene castor oil series (EL20, 30, 35, 40, 60, 80), polyoxyethylene hydrogenated castor oil series (CO40, RH40), One or more of sodium stearyl sulfate, ...

Embodiment 2

[0037] a kind of like figure 1 The n-octadecane phase change microemulsion of the present invention is shown, the phase change microemulsion includes 5g n-octadecane (98% AR grade), 0.97g octadecyl polyoxyethylene ether phosphate (technical grade), 0.15g Tween60, 1.5g n-pentanol, 0.53gNaCl and 10g water (ordinary drinking water is enough).

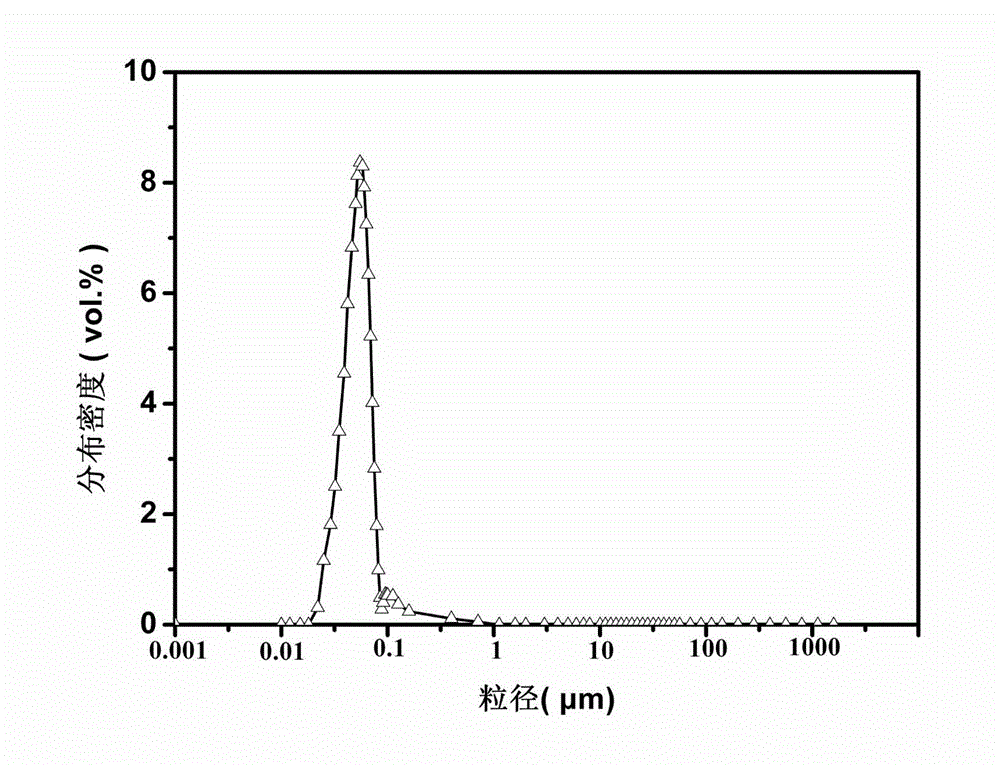

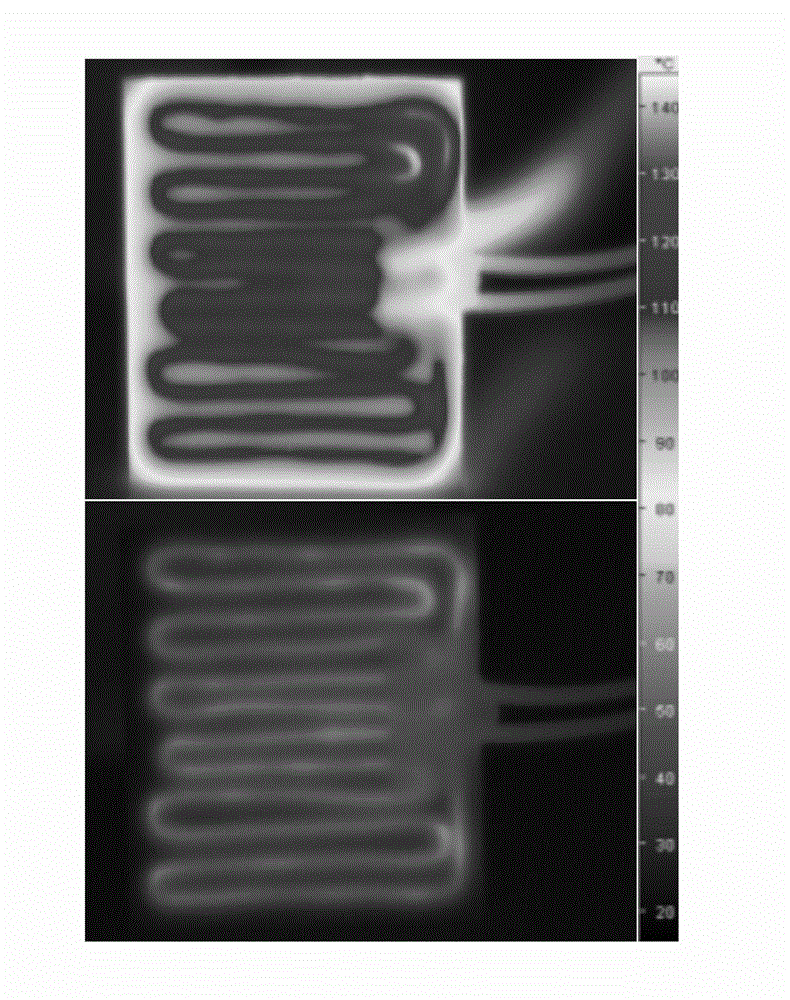

[0038]The preparation method of the n-octadecane phase-change microemulsion of the present embodiment comprises the following steps: first mix the stearyl polyoxyethylene ether phosphate of the above-mentioned quality, Tween60 and 2.5g n-amyl alcohol, and then add the above-mentioned quality Mix n-octadecane and NaCl in a 35°C water bath, add the remaining water, the system gradually changes from turbid to clear and transparent, and leave it at room temperature to obtain the n-octadecane phase-change microemulsion. The n-octadecane content in the emulsion is about 28wt.%. Use Mastersizer2000 laser particle size analyzer to test this prod...

Embodiment 3

[0040] A n-octadecane phase change microemulsion of the present invention, the phase change microemulsion includes 5g n-octadecane (98% AR grade), 0.88g castor oil polyoxyethylene ether (EL40), 1.25g RH40, 3.3 g n-butanol, 0.58g NaCl and 24g water (ordinary drinking water is sufficient).

[0041] The preparation method of the n-octadecane phase-change microemulsion of this embodiment includes the following steps: firstly mix the above-mentioned quality of EL40, RH40 and n-butanol evenly, then add the above-mentioned quality of n-octadecane and NaCl, and put it in a water bath at 35°C Stir evenly, add the rest of the water system gradually from turbid to clear and transparent, and stand at room temperature to obtain the n-octadecane phase-change microemulsion. The n-octadecane content in the phase-change microemulsion is about 14wt.%. Mastersizer2000 laser particle size analyzer test the particle size distribution of dispersed droplets in the phase change microemulsion is 10nm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com