Aluminate red phosphor activated by manganese ion and preparation method thereof

A red phosphor and aluminate technology, applied in the field of red phosphor and its preparation, can solve the problems affecting the commercialization of nitride phosphors, difficult to match with LED chips, etc., achieving low cost, easy operation, and improved crystal lattice. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

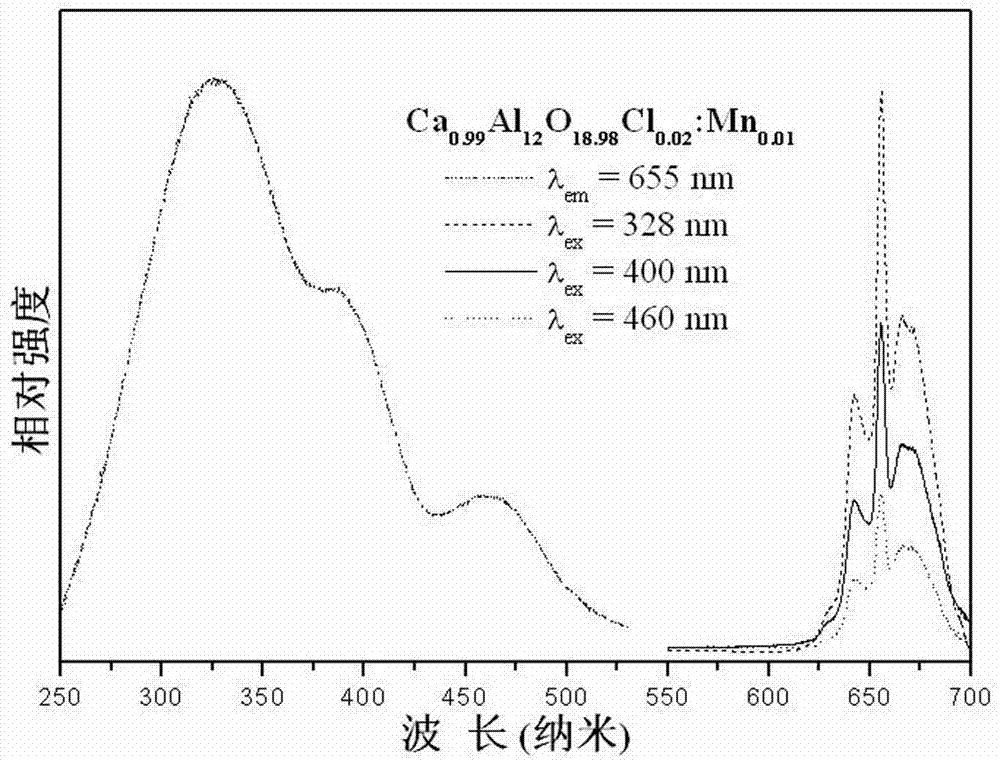

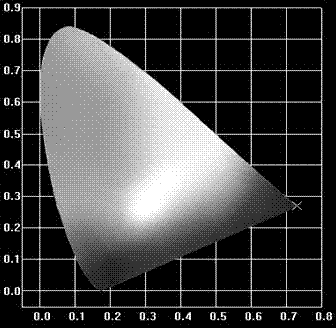

[0018] Example 1 Ca 0.99 Al 12 o 18.98 Cl 0.02 :Mn 0.01

[0019] Weigh 0.4904g of calcium carbonate, 3.0588g of aluminum oxide, 0.0058g of manganese carbonate, 0.0056g of anhydrous calcium chloride, and 0.0107g of boric acid, mix them uniformly, put them into a corundum crucible, put them into a high-temperature furnace, and sinter at 800°C for 1 hour, take it out after cooling, grind the calcined product and then sinter at 1630°C for 4 hours, pulverize the sintered product, wash it with deionized water, pass through a 400-mesh sieve, and separate the water and powder, dry the filter cake at 120°C, that is Aluminate red phosphor activated by manganese ions is obtained. The excitation and emission spectra of the phosphor at room temperature are shown in figure 1 , whose color coordinates are shown in figure 2 .

Embodiment 2

[0020] Example 2 Ca 0.999 Al 12 o 18.998 f 0.002 :Mn 0.001

[0021] Weigh 0.4994g of calcium carbonate, 3.0588g of alumina, 0.0006g of manganese carbonate, 0.0004g of calcium fluoride, and 0.0107g of boric acid, mix them evenly, put them into a corundum crucible, put them into a high-temperature furnace, and sinter at 800°C for 1 hour. Take it out after cooling, grind the calcined product and then sinter at 1630°C for 4 hours, crush the sintered product, wash it with deionized water, pass through a 400 mesh sieve, separate the water and powder, and dry the filter cake at 120°C to obtain manganese ions Activated aluminate red phosphor.

Embodiment 3

[0022] Example 3 Ca 0.89 Mg 0.1 Al 12 o 18.98 Cl 0.02 :Mn 0.01

[0023] Weigh respectively 0.4454g of calcium carbonate, 0.0202g of magnesium oxide, 3.0588g of aluminum oxide, 0.0058g of manganese carbonate, 0.0053g of ammonium chloride, and 0.0035g of boric acid. Sinter at ℃ for 1 hour, take it out after cooling, grind the burnt product and then sinter at 1630°C for 6 hours, pulverize the sintered product, wash with deionized water, pass through a 400-mesh sieve, separate the water and powder, and dry the filter cake at 120°C , that is, the aluminate red phosphor activated by manganese ions is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com