Preparation method and application of microbial manganese-carbon composite material

A composite material and microorganism technology, which is applied to the preparation of microbial-based manganese-carbon composite materials, and the application field of microbial-based manganese-carbon composite materials, can solve problems such as the preparation of environmental materials by manganese-oxidizing bacteria and their metabolites that have not yet been found, and achieve good practicality. Value and application prospects, fast response, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing a microbial-based manganese-carbon composite material, the preparation steps of which are:

[0021] (1) Add a certain amount of filter-sterilized HEPES buffer (pH 6-7) and 1ml1mol / lMnCl under sterile conditions 2 In the sterilized culture medium, the final concentration was 10mmol / L, and at the same time, 1% of the inoculum was inserted into the bacterial solution of manganese-oxidizing bacteria (preservation number CCTCC NO: M2012084) that had grown to the logarithmic phase, and the Place the flask in a 28°C 150r / min shaker for 10 days, centrifuge at 8000rpm for 5 minutes to collect the precipitate, wash the residual ions on the surface with ultrapure water, freeze-dry in a freeze dryer, and grind to obtain microbial secondary manganese oxide for use. The medium formula is as follows: yeast extract 0.5g, peptone 2g, agar 15g, artificial seawater (artificial seawater: NaCl13.14g, KCl0.56g, MgSO 4 .7H 2 O9.24g, CaCl 2 0.83g, add distilled water ...

Embodiment 2

[0023] Embodiment 2: the application of a kind of microorganism-based manganese-carbon composite material in dye wastewater treatment, its application process is:

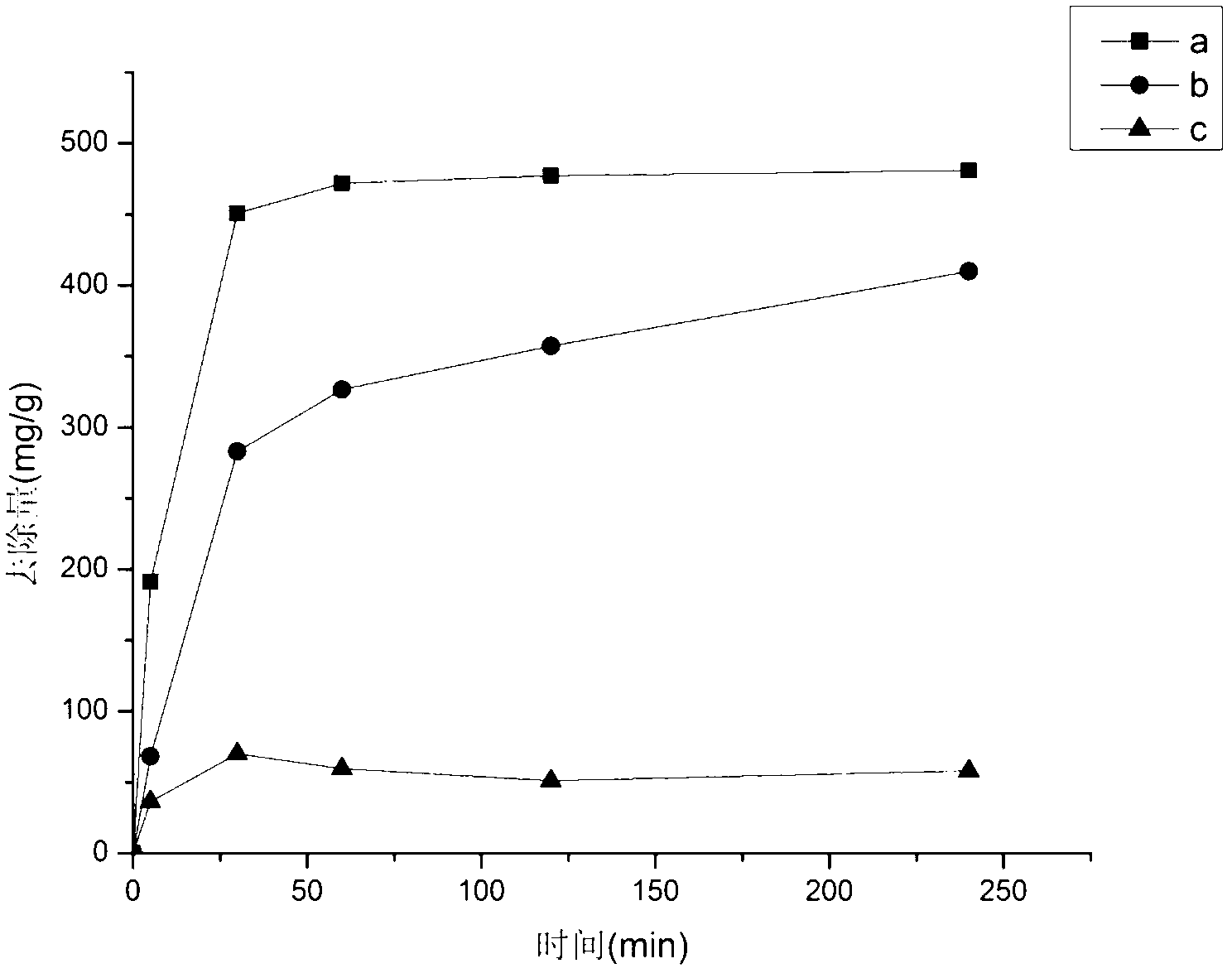

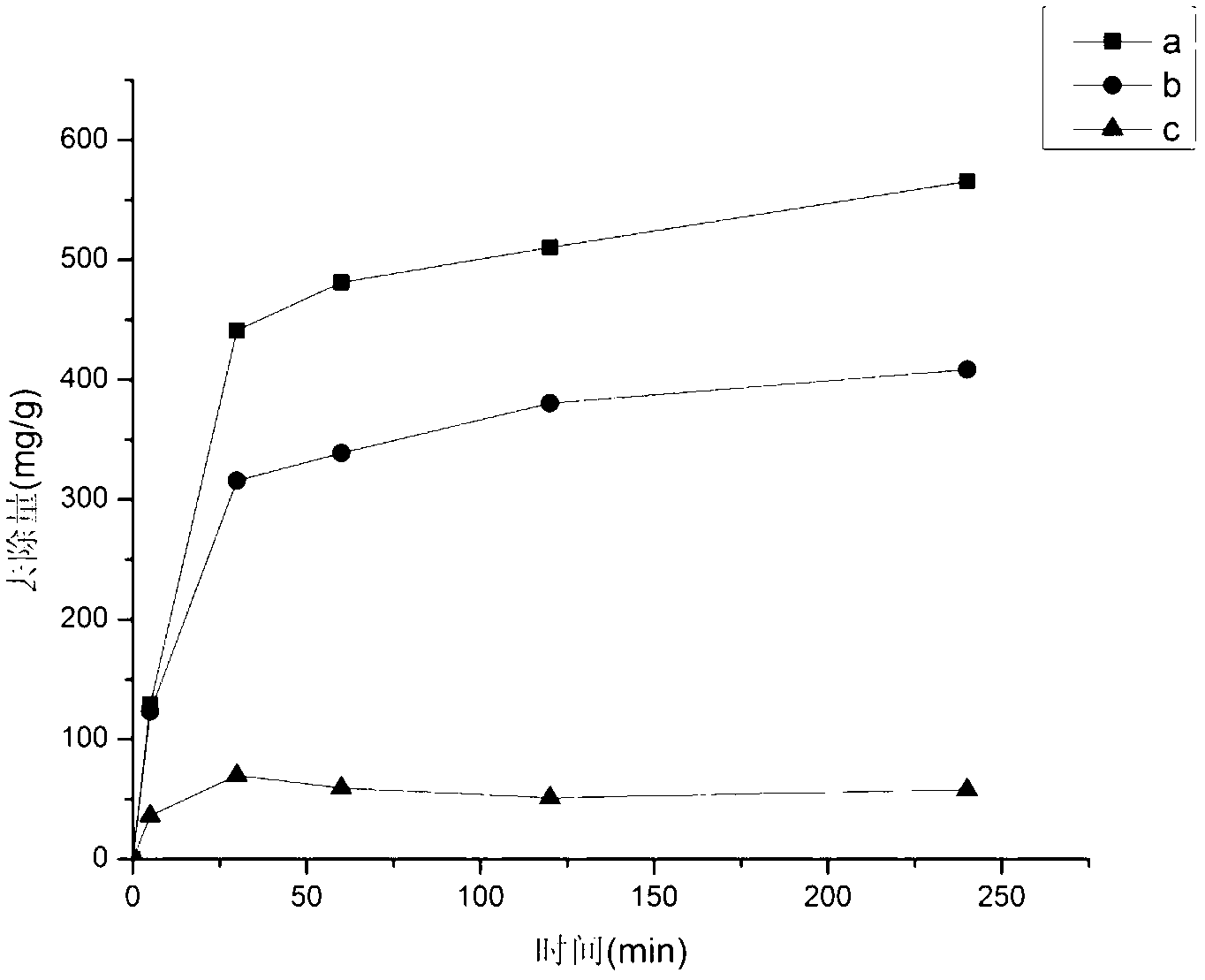

[0024] Get each 0.1g of the microorganism-based manganese-carbon composite material and commercial activated carbon obtained in Example 1, add 100ml500mg / l sodium indigo disulfonate respectively, shake, centrifuge after 5-240min, measure the concentration of dyestuff in the supernatant , according to the concentration difference of the dye before and after the treatment, the removal amount of the microbial-based manganese-carbon composites for the dye wastewater was calculated. The experimental results showed that the removal of sodium indigo disulfonate by microbial-based manganese-carbon composites and commercial activated carbon was 471 mg / g and 59 mg / g, respectively, within 60 minutes, the former being about 10 times that of the latter.

Embodiment 3

[0025] Embodiment 3: a kind of preparation method of microorganism-based manganese-carbon composite material, its preparation steps are:

[0026] Add a certain amount of filter-sterilized HEPES buffer (pH 6-7) and 1ml 1mol / l MnCl under sterile conditions 2 Place it in the culture medium so that the final concentration is 10mmol / l. At the same time, insert the manganese oxidizing bacteria solution that has grown to the logarithmic phase with 1% inoculum, and put the triangular flask into a shaker at 28°C and 150r / min for cultivation. On 10 days, centrifuge at 8000 rpm for 5 minutes to collect the precipitate, wash the residual ions on the surface with ultrapure water, freeze-dry in a freeze dryer, and grind to obtain microbial secondary manganese oxide for later use.

[0027] Take 1g of the microbial secondary manganese oxide material prepared in the previous step, mix it with the activator (NaOH) at a mass ratio of 1:4, add 3ml-5ml deionized water and stir, completely immerse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com