Graphene-hydroxyl lithium composite, and preparation method and application thereof

A composite material, graphene hydroxyl technology, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as low specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

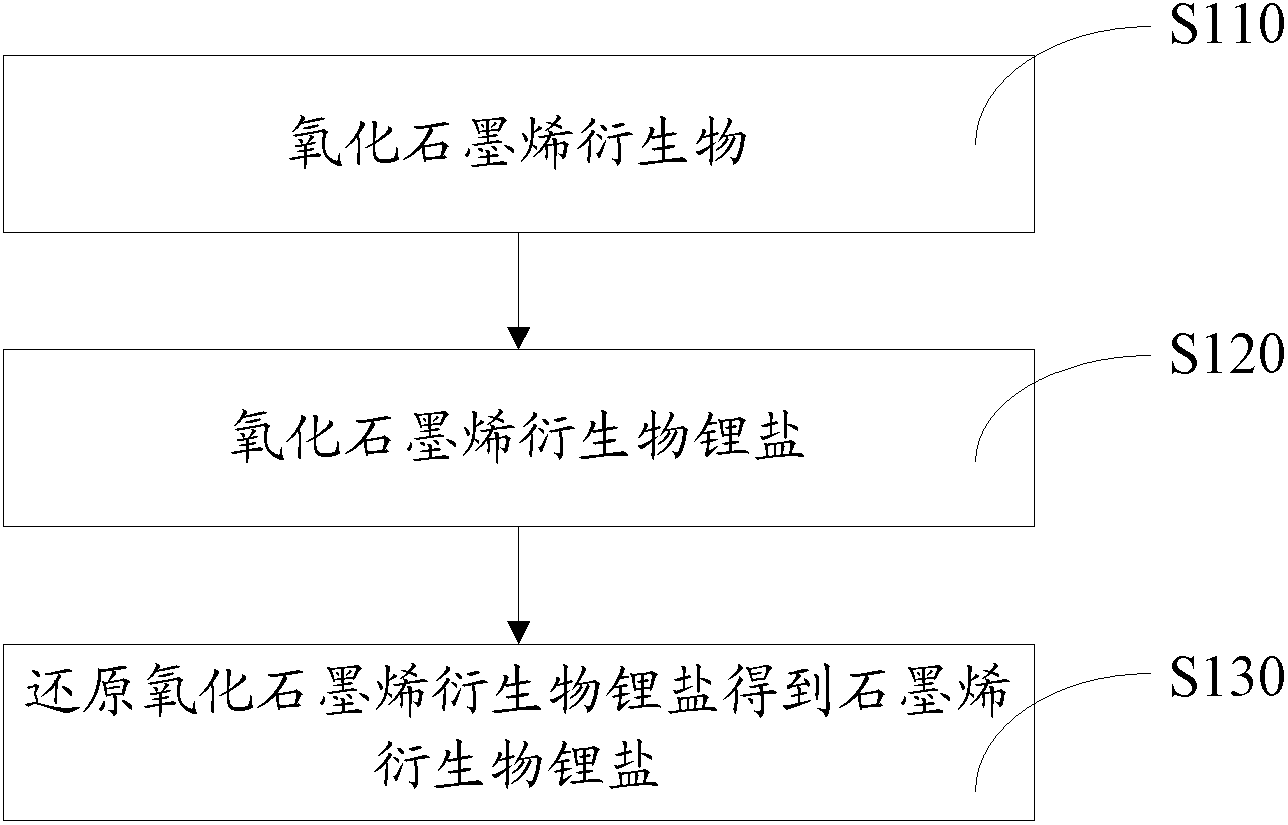

[0023] In addition, the present invention also provides a preparation method of graphene hydroxylithium composite material, such as figure 1 shown, including the following steps:

[0024] Step S110: Prepare graphene oxide hydroxyaniline: prepare graphene oxide suspension and hydroxyaniline alcohol solution respectively, mix the two according to the mass ratio of graphene oxide: hydroxyaniline = 3:5, and reflux at 80° C. for 24 hours Obtain graphene oxide hydroxyaniline. The amine groups in the hydroxyaniline react with the carbon atoms in the epoxy structure in the graphene oxide to form o-hydroxyaniline, and the hydroxyaniline is covalently bonded to the graphene oxide.

[0025] Wherein, the graphite oxide suspension is obtained by dissolving graphite oxide in an organic solvent and ultrasonically dispersing it. Preferably, the graphite oxide suspension is a graphite oxide N,N-dimethylformamide solution with a mass concentration of 0.5-1 g / L.

[0026] Further, graphite oxi...

Embodiment 1

[0050] Embodiment 1 graphene hydroxylithium composite material

[0051] Graphite → graphite oxide → graphene oxide hydroxyaniline → graphene oxide hydroxylithium composite material → graphene hydroxylithium composite material

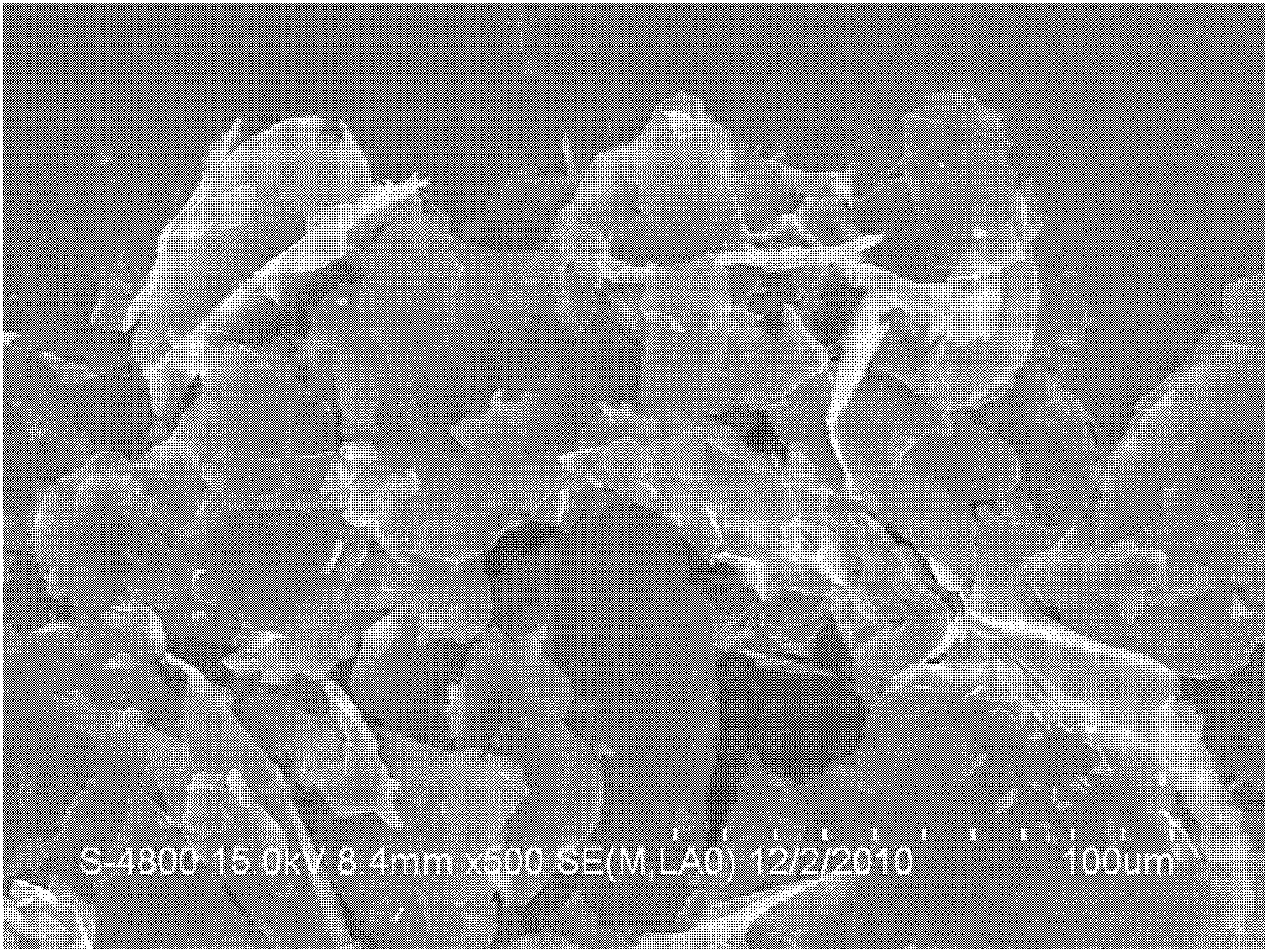

[0052] (1) Graphite: natural flake graphite with a purity of 99.5%.

[0053] (2) Graphite oxide: 20g natural flake graphite powder, 10g potassium persulfate and 10g phosphorus pentoxide are added in the concentrated sulfuric acid of 80 ℃, stir evenly, cool more than 6 hours, suction filter, wash to neutrality, dry, obtain mixed samples;

[0054] Add the dried mixed sample to 230mL of concentrated sulfuric acid at 0°C, then add 60g of potassium permanganate, keep the temperature of the system below 20°C, then keep it in an oil bath at 35°C for 30 minutes, then slowly add 920mL Deionized water;

[0055] After 15 minutes, add 2.8L of deionized water to the system until the color of the mixture turns bright yellow, filter while hot, then wash with 5L of ...

Embodiment 2

[0060] Embodiment 2 graphene hydroxylithium composite material

[0061] (1) Graphite oxide: with embodiment 1.

[0062] (2) Graphene oxide hydroxyaniline: Dissolve graphite oxide in DMF solution, and ultrasonically disperse to prepare a graphene oxide suspension with a concentration of 0.5g / L; dissolve 3,4,5-trihydroxyaniline in methanol to prepare 3,4,5-trihydroxyaniline solution with a concentration of 0.5g / L; take 30mL of graphene oxide suspension and add it to a three-neck flask, add 50mL of 3,4,5-trihydroxyaniline solution under vigorous stirring, at 80°C Reflux for 24 hours to obtain a graphene oxide derivative, and dry to obtain a graphene oxide derivative powder.

[0063] (3) Graphene oxide hydroxylithium composite material: ultrasonically disperse the graphene oxide derivative powder obtained in step (3) into water and mix with excess lithium hydroxide, stir at room temperature for 24 hours until fully reacted completely, and let stand to remove excess lithium hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com