Method for preparing alkyl naphthalene polycondensation catalyst

A technology of polycondensation catalyst and alkylnaphthalene, which is applied in the field of preparation of polycondensation catalyst, can solve the problems of inability to realize large-scale industrial production, non-compliance, low catalytic selectivity and conversion rate of cobalt salt catalyst, and achieve improved catalytic activity selectivity As well as the effect of high moldability, catalytic selectivity and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

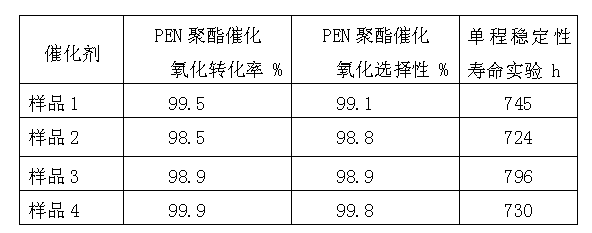

Examples

Embodiment 1

[0016] A molecular sieve containing Ti, Mg, Al, Si is used as a catalytically active monomer, and it is ultrafinely pulverized to d 50 =9.8μm, modified, the modified medium is a mixture of ammonium chloride, tetrapropylammonium hydroxide and methanol with a mass ratio of 2:0.08:0.3, the modified condition is 160°C, 1.4Mpa, modified Sexual treatment for 8 hours. The modified catalytically active monomer was vacuum-dried at a low temperature of 60°C, a high-purity silica sol was selected as a binder, and sample 1 was obtained through extrusion molding, drying and roasting.

Embodiment 2

[0018] A ZSM-5 molecular sieve containing Ti, Co, Al and Si is used as a catalytically active monomer, which is ultrafinely pulverized to d 50 =10.5μm, modified, the modified medium is ammonium nitrate, ammonium sulfate, tetraethylammonium hydroxide, tetrapropylammonium hydroxide, ethanol and For the solution of the mixture of propanol, the modification condition is 160°C, 1.6Mpa, and the modification treatment is 12 hours. The modified catalytically active monomer was vacuum-dried at a low temperature of 45°C, a high-purity silica sol was selected as a binder, and sample 2 was obtained through extruding, drying and roasting.

Embodiment 3

[0020] A ZSM-5 molecular sieve containing Ti, Mg, Co, and Si was used as a catalytically active monomer, which was ultrafinely pulverized to d 50 =11.2μm, modified, the modified medium is a solution of ammonium nitrate, ammonium carbonate, tetramethylammonium hydroxide, ethanol and methanol with a mass ratio of 1.2:0.8:0.12:0.25:0.12, the modified condition 180°C, 2.3Mpa, modification treatment for 11 hours. The modified catalytically active monomer was vacuum-dried at a low temperature of 50°C, a high-purity silica sol was selected as a binder, and sample 3 was obtained through extruding, drying and roasting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com