Method for preparing p-type ZnO nanowire

A p-type, nanotechnology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems affecting the performance of devices, the quality of nano zinc oxide crystals is not high, etc., to achieve good repeatability, crystal Good quality, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

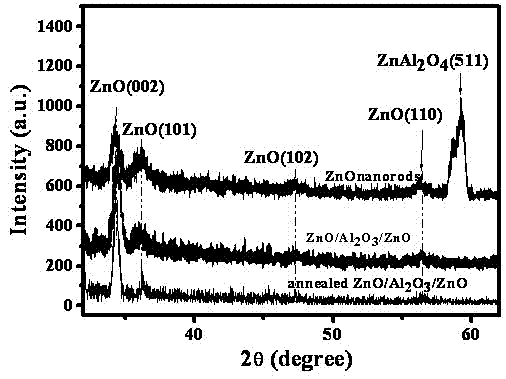

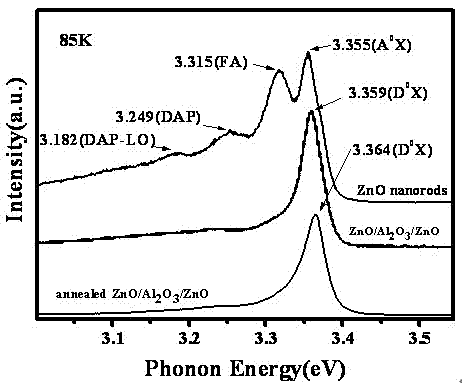

Embodiment 1

[0008] 1. Deposit a ZnO film as a seed layer on a cleaned silicon substrate by ALD method. The substrate temperature of the reaction chamber is 170°C, the pulse time (pulse) of the precursor source diethyl zinc and water is 0.02s, the nitrogen flushing time (waiting) is 0.5s, and the cycle is 1000 times; growth of ZnO nanorods. Configure 200ml of a mixed aqueous solution of zinc acetate and hexamethylenetetramine with a concentration of 0.01M, place the aqueous solution and the above-mentioned sinking bottom in the reactor, the solution volume is two-thirds of the capacity of the reactor, and place the reactor in a blast Keep in a drying oven at 90°C for 24h; 3. Take out the above sample and rinse it with deionized water for 10s, then place it in the air to dry naturally, then anneal at a low temperature of 400°C for half an hour to remove excess salt and other impurities on the surface of the nanorods; 4 1. Coating aluminum oxide layer and zinc oxide layer by ALD method. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com