Soybean peptide for promoting lactobacillus proliferation and improving lactobacillus survivability as well as preparation method and application thereof

A technology of soybean polypeptide and lactic acid bacteria, which is applied in the field of deep processing of soybean protein, can solve the problems of improving the viability of lactic acid bacteria and low yield of soybean polypeptide, etc., to protect the activity of lactic acid bacteria, facilitate enzymatic hydrolysis reaction, and extend enzyme The effect of solution time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

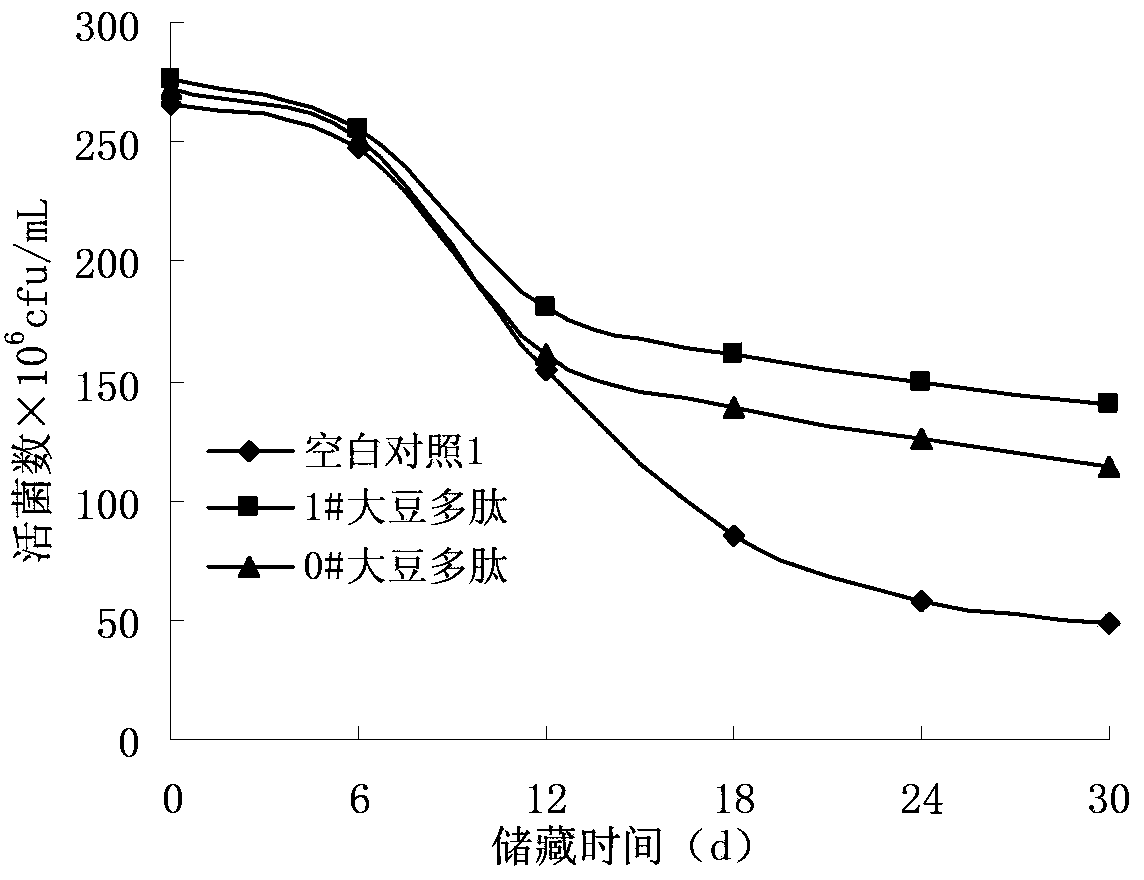

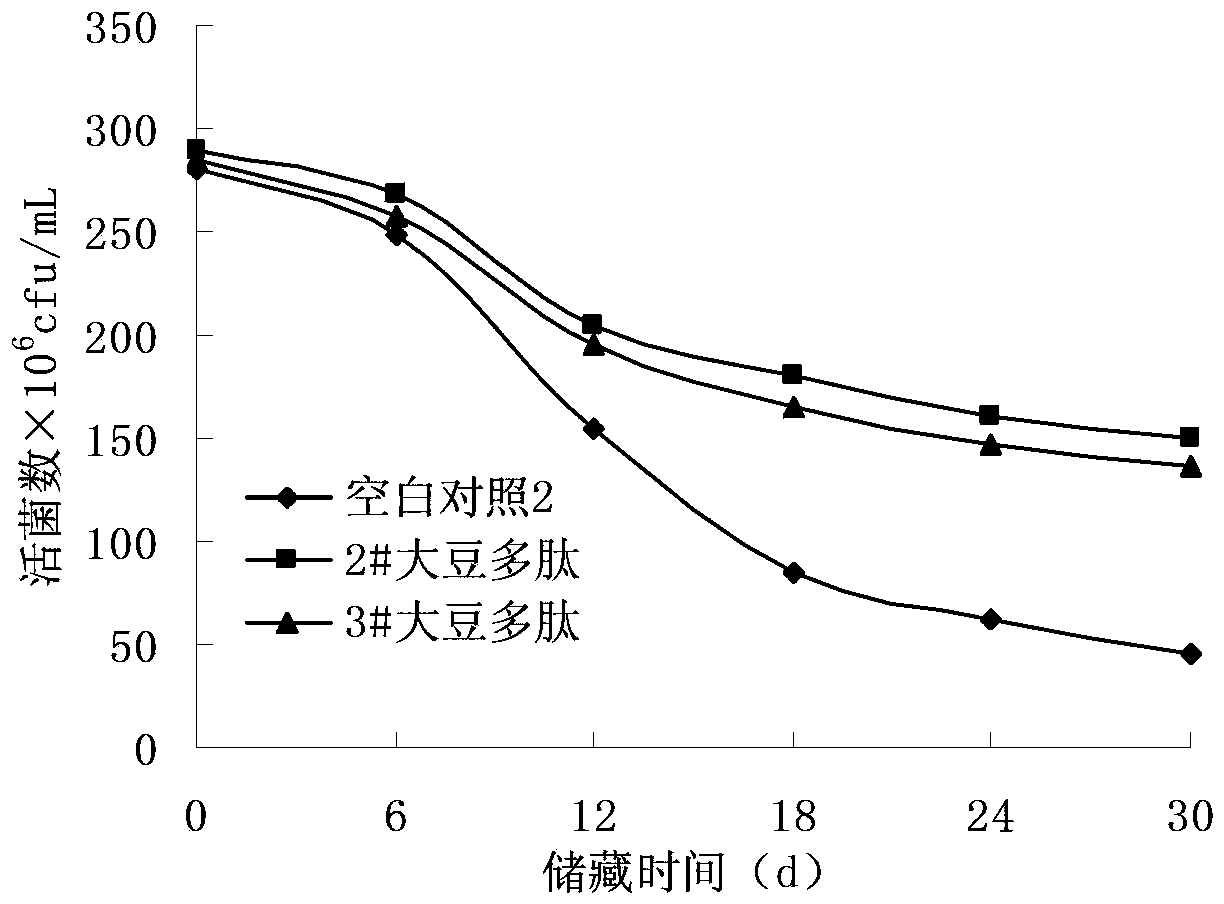

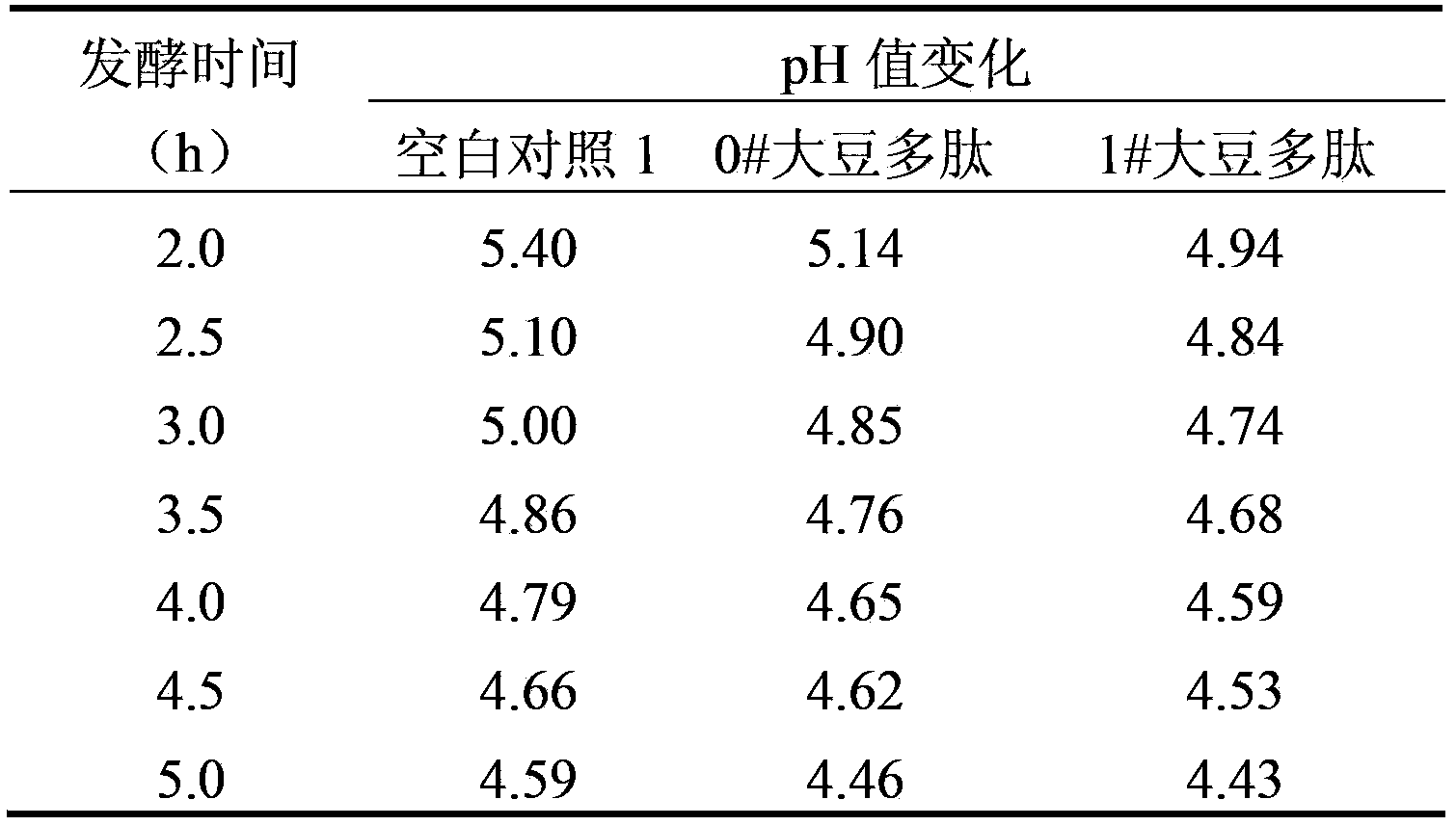

Examples

Embodiment 1

[0044] (1) Moisture adjustment: select high-quality soy protein isolates without mold, deterioration and agglomeration, 10% (w / w) moisture content of soybean protein isolate and 20% (w / w) moisture content of soybean protein with 1: 1 ratio, mix thoroughly to obtain soybean protein with a moisture content of 15% (w / w).

[0045] (2) High-temperature extrusion: Extrude the soybean protein with a twin-screw extruder at a temperature of 200°C and a rotational speed of 80r / min. After the extrusion is finished, the soybean protein is crushed with a high-speed mixer at 1000 r / min, and passed through a 20-mesh sieve.

[0046] (3) Enzymolysis: Prepare the extruded and sieved soybean protein into a 5% (w / w) suspension with water, heat to 45°C, and adjust the pH value of the suspension with 0.1mol / L NaOH solution Adjust to 9; then add alkaline protease Alcalase 2.4L equivalent to 0.2% of soybean protein (product of Novozymes, Denmark, enzyme activity 6.9×10 4 U / mL), at 45°C, the enzymat...

Embodiment 2

[0057] (1) Moisture adjustment: select high-quality soybean protein isolates without mold, deterioration, and agglomeration, soybean protein isolates with a moisture content of 7% (w / w), and use spray humidification to increase the moisture content to 20% (w / w).

[0058] (2) High-temperature extrusion: Extrude the soybean protein with a twin-screw extruder at a barrel temperature of 120°C and a rotational speed of 145r / min. After the extrusion is finished, the soybean protein is crushed with a high-speed mixer at 1000 r / min, and passed through a 20-mesh sieve.

[0059] (3) Enzymolysis: Prepare the extruded and sieved soybean protein into a 15% (w / w) suspension with water, heat to 55°C, and adjust the pH value of the suspension with 0.1mol / L NaOH solution Adjust to 7; then add papain equivalent to 2% of soybean protein (Guangzhou Enzyme Preparation Factory, enzyme activity 3.2×10 4 U / mL), the condition of enzymolysis is at 55°C, and the enzymolysis time is 12h. During the en...

Embodiment 3

[0067] (1) Moisture adjustment: select high-quality soybean protein isolates without mold, deterioration, and agglomeration, soybean protein isolates with a moisture content of 7% (w / w), and use spray humidification to increase the moisture content to 10% (w / w).

[0068] (2) High-temperature extrusion: Extrude the soybean protein with a twin-screw extruder at a temperature of 165°C and a rotational speed of 200r / min. After the extrusion is finished, the soybean protein is crushed with a high-speed mixer at 1000 r / min, and passed through a 20-mesh sieve.

[0069] (3) Enzymatic hydrolysis: Prepare the extruded pretreated soybean protein into a 10% (w / w) suspension, heat it to 60°C, and adjust the pH value of the suspension to 7 with 0.1mol / L NaOH solution; Then add neutral protease equivalent to 1% of soybean protein (product of Novozymes, Denmark, enzyme activity 2.7×10 4 U / g), the condition of enzymolysis is at 50°C, and the enzymolysis time is 6h. During the enzymolysis pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com