White-light LED (light-emitting diode) containing novel solid-state transparent fluorescent materials and preparation method thereof

A fluorescent material, transparent technology, used in white LED. Field, can solve problems such as yellow aperture, blue spot, phosphor efficiency decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

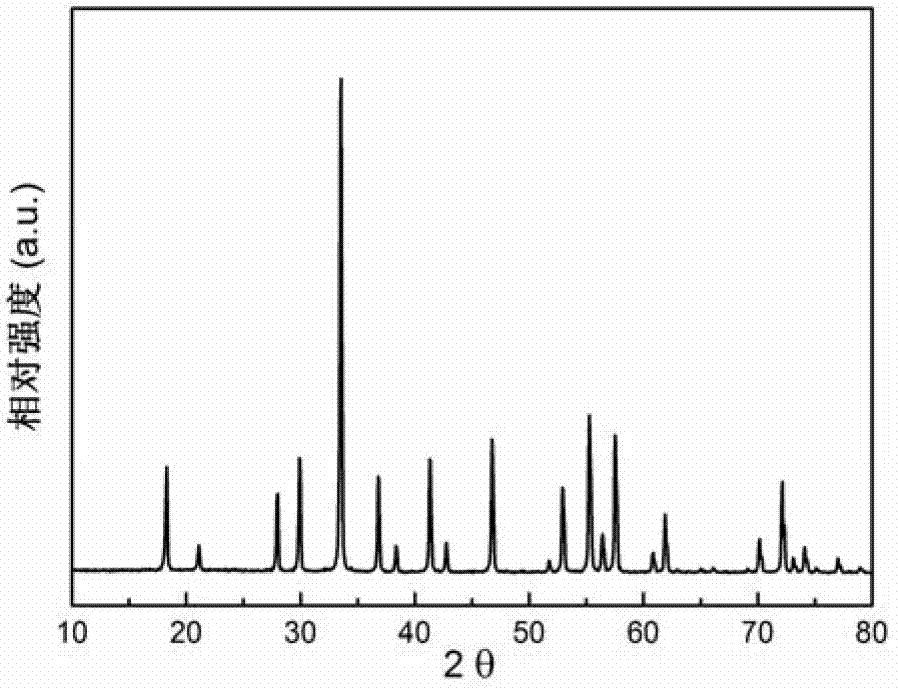

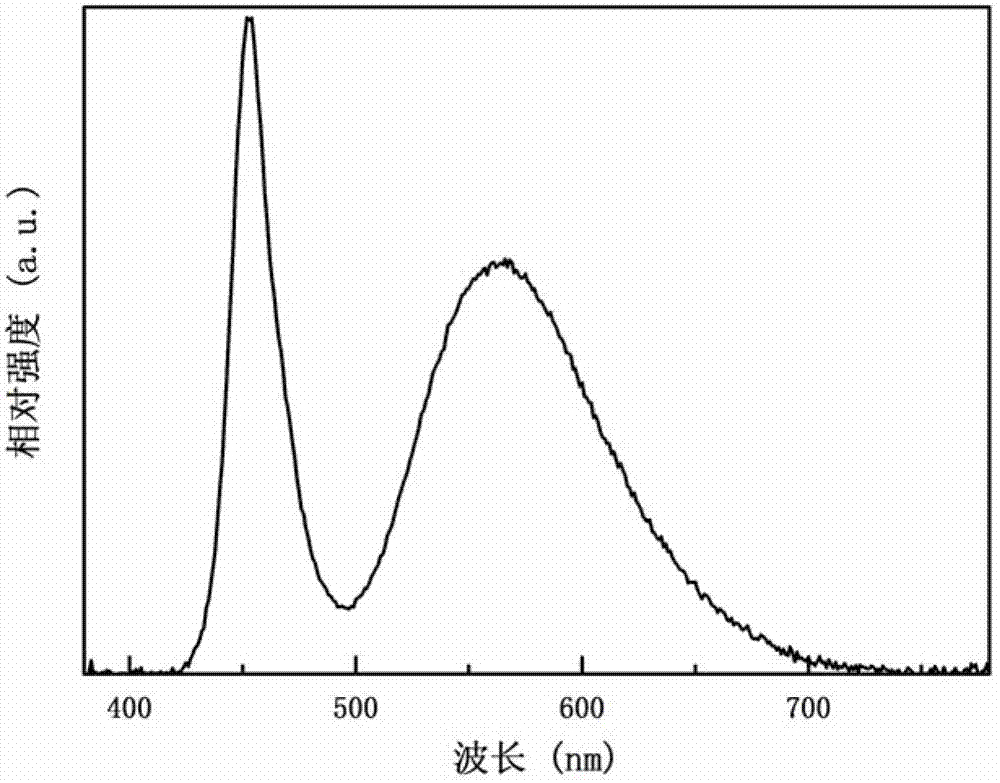

[0110] Press (Ce 0.06% Y 99.94% ) 3 Al 5 o 12 Chemical composition weighing α-Al 2 o 3 Powder, Y 2 o 3 Powder, Ce 2 o 3 Powder raw materials, add 0.1200g of TEOS and 0.5400g of polyvinyl butyral into the high-purity agate ball milling tank for the mixed powder, add 80g of high-purity agate balls, 12g of absolute ethanol, and put it into the ball mill after 20 hours Dry in oven for 15h. Grind with a mortar and sieve the powder to obtain a powder with a thickness of 45-75 μm, pressurize in one direction with a pressure axis of 10Mpa respectively, press into the original sheet, and then cold isostatically press at 200Mpa. Debinding at 900°C for 20 hours under normal pressure, and sintering the green body after debinding in vacuum, the heating rate is 10°C / min, the sintering temperature is 1850°C, the heating rate is 10°C / min, and the sintering time is 15 hours, the sintered sample was annealed at 1500° C. for 10 hours, and finally the sample was polished, and the thick...

Embodiment 2

[0113] Weigh the following powder materials according to the mole percentage in Table 1:

[0114] Table 1

[0115] raw material

NaF

MgO

Ce 2 o 3

Y 2 o 3

al 2 o 3

SiO 2

Composition (mol%)

5%

2%

2%

20%

35%

36%

[0116] The raw materials are mixed evenly by ball milling and then poured into a platinum crucible to melt. The melting temperature is 1650°C. After 2 hours of heat preservation, the glass melt is poured into a cast iron mold, and then placed in a high-temperature furnace for annealing. The annealing temperature is 750°C. After 2 hours, it was cooled to room temperature with the furnace to obtain a transparent glass phosphor with a thickness of 0.8 mm.

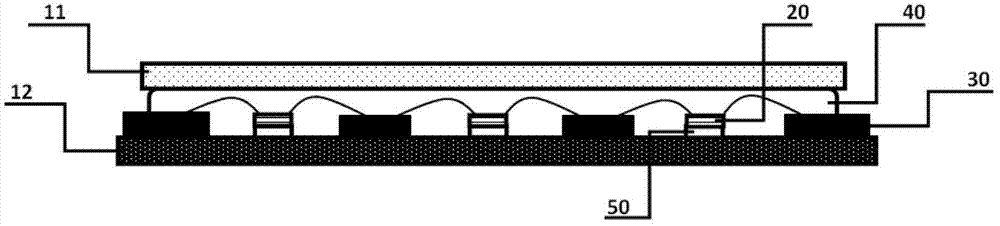

[0117] Such as Figure 4 As shown, the LED chip 20 with a peak wavelength of 460 nm is fixed on the crystal-bonding position of the alumina ceramic substrate 12 by using commercially available silica gel 50, and the silica gel 50 is cu...

Embodiment 3

[0119] Press (Ce 0.06% Gd 10% Y 89.94% ) 3 Al 5 o 12 Chemical composition weighing α-Al 2 o 3 Powder, Y 2 o 3 Powder, Gd 2 o 3 with Ce 2 o 3 Powder raw material, add 0.1200g of TEOS and 0.5400g of polyvinyl butyral to the mixed powder into a high-purity agate ball mill jar, add 80g of high-purity agate balls, 12g of absolute ethanol, and put it into the ball mill after 20 hours Dry in oven for 15h. Grind with a mortar and sieve the powder to obtain a powder with a thickness of 45-75 μm, pressurize in one direction with a pressure axis of 10Mpa respectively, press into the original sheet, and then cold isostatically press at 200Mpa. Debinding at 1500°C for 20 minutes under normal pressure, and sintering the green body after debinding in vacuum, the heating rate is 10°C / min, the sintering temperature is 1200°C, and the sintering time is 20h. The sintered sample was annealed at 1500° C. for 1 hour, and finally the sample was polished. The thickness of the polished s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Color temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Color temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com