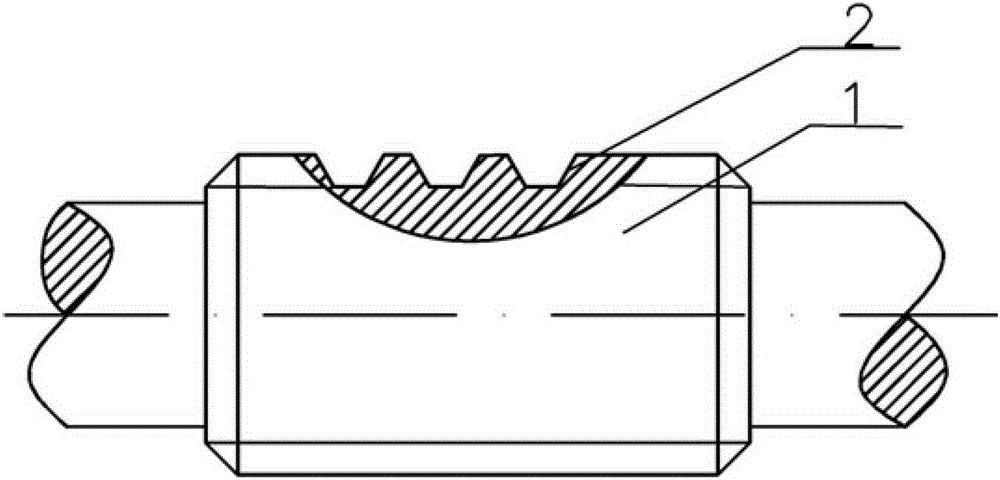

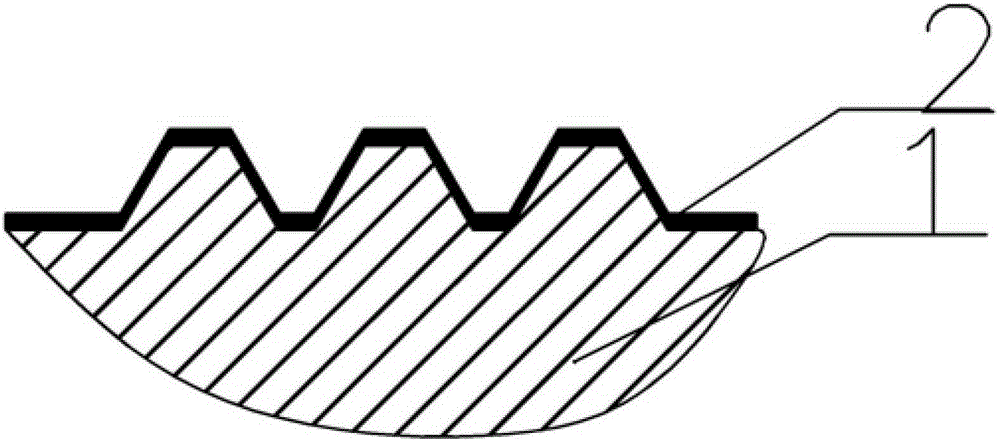

Anti-friction coating layer and method and application of screw compressor

A technology of anti-friction coating and coating layer, applied in the direction of rotary piston machinery, mechanical equipment, machine/engine, etc., can solve problems such as corrosion and deformation, and achieve the effect of improving air quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The formulation of molybdenum disulfide antifriction coating is as follows:

[0024] Solid lubricant: 10% molybdenum disulfide, 5% tungsten disulfide, 8% graphite, 3% graphite fluoride, 2% antimony trioxide;

[0025] The wear-resistant agent is: carbon nanotube 1%, silicon nitride 2%, nano emery 2%, corundum 3%, silicon dioxide 1%, fluorinated graphite 5%;

[0026] Adhesive: 9% polyester resin, 6% epoxy resin, 7% acrylic resin;

[0027] Additives: 4% powder surface treatment agent, 2% resin active agent;

[0028] Vehicle: N-methylpyrrolidone 30%.

[0029] Active additives are added to the solid lubricant to activate the surface of the solid lubricant so that it can better combine with the polymer material.

[0030] After mixing, the specific gravity is 1200±60 g / L, it is gray-black, and the flash point is 100°C.

[0031] The specific steps of coating the composite molybdenum disulfide antifriction coating on the screw rod are as follows:

[0032] The first step is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com