Chemical modification method of bagasse for purification

A technology of chemical modification and bagasse, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of wood chip type and specification limitations, large performance changes, limited sources, etc., to improve activation efficiency, High degree of fibrosis and the effect of improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

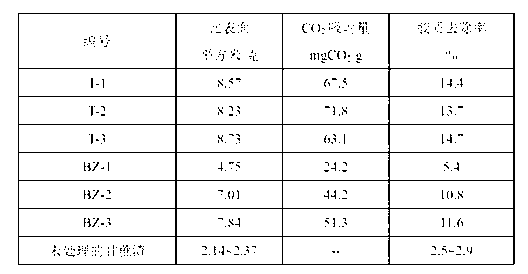

Embodiment 1

[0038] Take 5.5 kg of bagasse with a particle size of 4-10 mesh and put it into a 50-liter pressure-resistant stirred reactor with a polytetrafluoroethylene lining and a heating tube, then add 25 kg of 0.2mol / L sulfuric acid aqueous solution, and heat it at 60°C Under the conditions of airtight stirring and impregnating for 6.5 hours, then filtered, washed 4 times with water 4 times the volume of bagasse, drained, put in an oven at 80°C for 5 hours, the water content of bagasse was 13%. Gained bagasse is then put into 50 liters of pressure-resistant stirred reactor with polytetrafluoroethylene lining and heating pipe, add 25 kilograms of tetrahydrofuran, dimethyl sulfoxide, urea, sodium sulfite, sodium ethylate, ethanol and water Mixed solvents with a mass ratio of 0.15:0.2:0.5:0.2:5:0.7:80 were reacted under airtight conditions at 60°C for 24 hours, filtered and washed 7 times with water 4 times the volume of bagasse, and then drained , put it in an oven at 115°C and bake for...

Embodiment 2

[0040] Take 6.5 kilograms of bagasse with a particle size of 4-15 mesh and put it into a 50-liter pressure-resistant stirred reactor with a polytetrafluoroethylene lining and a heating tube, then add 20 kilograms of 0.15mol / L sulfuric acid aqueous solution, and heat it at 70°C Under the conditions of airtight stirring and impregnation for 5 hours, then filtered, washed 4 times with water 4 times the volume of bagasse, drained, put in an oven at 60 ° C for 4 hours, the water content of bagasse is 12%. Gained bagasse is then put into a 50-liter pressure-resistant stirred reactor with a polytetrafluoroethylene lining and a heating pipe, and 20 kilograms of tetrahydrofuran, dimethyl sulfoxide, urea, sodium sulfite, sodium hydroxide, ethanol and water are added. Mixed solvents with a mass ratio of 0.15:0.1:0.6:0.3:6:0.5:60 were reacted under airtight conditions at 50°C for 48 hours, filtered and washed 6 times with water 3.5 times the volume of bagasse, and drained Dry it and put i...

Embodiment 3

[0042] Take 4 kg of bagasse with a particle size of 15-30 mesh and put it into a 50-liter pressure-resistant stirring reactor with a polytetrafluoroethylene lining and a heating tube, then add 18 kg of 0.45mol / L sulfuric acid aqueous solution, Under the condition of airtight stirring and impregnation for 8 hours, then filtered, washed 4 times with water 5 times the volume of bagasse, drained, put in an oven for 4 hours at 70°C, the moisture content of bagasse was 15%. Gained bagasse is then put into a 50-liter pressure-resistant stirred reactor with a polytetrafluoroethylene lining and a heating pipe, and 30 kilograms of tetrahydrofuran, dimethyl sulfoxide, urea, sodium sulfite, potassium hydroxide, ethanol and water are added. Mixed solvents with a mass ratio of 0.12:0.2:0.55:0.3:9:0.6:100 were reacted for 72 hours under airtight conditions at 70°C, filtered and washed 6 times with water 4 times the volume of bagasse, and then drained. Dry it and put it in an oven at 90°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com