A kind of method for preparing and producing nickel buckle cathode plate

A cathode plate, nickel button technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of low production efficiency of nickel buttons, difficult to peel off nickel buttons, and irregularities, so as to facilitate tripping and reduce labor intensity. , the effect of round shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

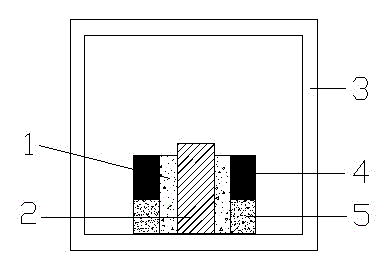

[0017] like figure 1 and 2 Put a stainless steel rod 2 with a diameter of 10 mm and a length of 12 mm into a ceramic tube 5 with an inner diameter of 16 mm, a wall thickness of 5 mm, and a length of 5 mm, and at the same time place the graphite tube 4 on the ceramic tube 5 to cover the stainless steel rod exposed from the ceramic tube 5 2. The mass ratio of aluminum powder, iron oxide, chromium oxide, nickel oxide, and titanium oxide is 28:60:8.5:4:4.5, mixed and dried at 80°C for 1 hour to prepare the reaction material, and the amount of iron powder added The reaction material is 27% of the total weight of the reaction material, and then the reaction material 1 is loaded into the gap between the stainless steel rod 2, the ceramic tube 5 and the graphite tube 4, and then heated to 870 ° C in the resistance furnace 3 and kept for 8 minutes, and then cooled with the furnace , when reaching the redox reaction temperature, the reaction occurs , the heat released by the reaction...

Embodiment 2

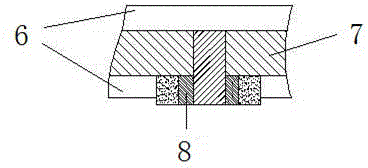

[0019] Put a stainless steel rod with a diameter of 10mm and a length of 12mm into a ceramic tube with an inner diameter of 16mm, a wall thickness of 5mm, and a length of 5mm. At the same time, place the graphite tube on the ceramic tube to cover the stainless steel rod exposed from the ceramic tube. The mass ratio of iron, chromium oxide, nickel oxide, and titanium oxide is 28:60:8.5:4:4.5, mixed and dried at 90°C for 1 hour to prepare a reaction material, and the amount of iron powder added is 25% of the total weight of the reaction material. %, then put the reaction material into the gap between the stainless steel rod and the ceramic tube and the graphite tube, then heat it to 900°C and keep it for 10 minutes, then cool with the furnace, when it reaches the redox reaction temperature, the reaction occurs , the heat released by the reaction melts all the reactant powders. During the heat preservation process, the reduced iron, nickel, chromium, and titanium sink to the bott...

Embodiment 3

[0021] Put the stainless steel rod into the ceramic tube, and place the graphite tube on the ceramic tube to cover the stainless steel rod exposed from the ceramic tube. The mass ratio of aluminum powder, iron oxide, chromium oxide, nickel oxide, and titanium oxide is 28: Mix 60:8.5:4:4.5 and dry at 100°C for 1 hour to prepare the reaction material, and the amount of iron powder added is 30% of the total weight of the reaction material, and then the reaction material is loaded into stainless steel rods, ceramic tubes and graphite tubes In the gap, heat it to 850°C and hold it for 9 minutes, then cool with the furnace, when it reaches the oxidation-reduction reaction temperature, the reaction occurs , the heat released by the reaction melts all the reactant powders. During the heat preservation process, the reduced iron, nickel, chromium, and titanium sink to the bottom due to their specific gravity, and the lighter alumina floats on the upper part. At the same time, the titani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com