Citric ester plasticizer and preparation method thereof

A technology of citrate ester and plasticizer, which is used in additives or additives, environmentally friendly non-toxic citrate ester plasticizers, food packaging plastics, medical equipment and children's toys. The use range of ester plasticizers, easy precipitation and migration, etc., achieve the effect of improving processing performance and product performance, facilitating industrial production, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

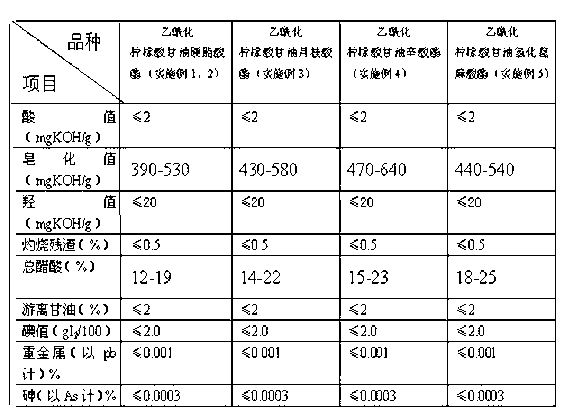

[0020] Add 250Kg of citric acid, 455Kg of glyceryl monostearate and 370Kg of n-butanol into the reaction kettle, add 8.5Kg of p-toluenesulfonic acid, heat to 110-130°C under normal pressure, and carry out reflux esterification reaction through the water separator , 5-6 hours measured acid value less than 5.0 can stop the reaction. Then raise the temperature to 160-170°C under vacuum, and distill off about 180Kg of excess n-butanol (which can be recycled). After cooling down to 50-60°C, add 270Kg of acetic anhydride, and carry out the acetylation reaction at 100-125°C. After 2-3 hours, the reaction is complete and the by-product acetic acid is distilled out under vacuum. After neutralization, washing, drying and other refining processes, the reaction end point is controlled by measuring the acid value, saponification value, and hydroxyl value. After meeting the requirements, it can be filtered and packaged to become the finished product of acetylated glyceryl citrate monosteara...

Embodiment 2

[0022] In the reaction kettle, react 195Kg of measured citric acid with 350 Kg of glyceryl monostearate to generate glyceryl monostearate of citric acid, add 180Kg of ethanol, add 5Kg of sulfuric acid dropwise under stirring, and heat to 110-120°C , carry out the reflux esterification reaction, and the acid value measured in 8-9 hours is less than 3.0 to stop the reaction. Then raise the temperature to 170-180°C, and distill off about 90Kg of excess ethanol (which can be recycled). After cooling down to 50-60°C, add 210Kg of acetic anhydride, and carry out acetylation reaction at 100-125°C. After 2-3 hours of complete reaction, turn on vacuum to distill out the by-product acetic acid. After neutralization, washing, drying and other refining processes, the reaction end point is controlled by measuring the acid value, saponification value, and hydroxyl value. After meeting the requirements, it can be filtered and packaged to become the finished product of acetylated glyceryl cit...

Embodiment 3

[0024] Add 230Kg of citric acid, 330Kg of glyceryl monolaurate and 310Kg of n-hexanol into the reaction kettle, add 8Kg of p-toluenesulfonic acid, heat to 140-150°C under vacuum, and carry out reflux esterification reaction through the water separator, 6 The reaction can be stopped if the acid value measured in -7 hours is less than 5.0. Then raise the temperature to 140-150°C under vacuum, and distill off about 120Kg of excess n-hexanol (which can be recycled). After cooling down to 50-60°C, add 250Kg of acetic anhydride, and carry out acetylation reaction at 120-130°C. After 2-3 hours, turn on the vacuum to distill out the by-product acetic acid. After neutralization, washing, drying and other refining processes, the reaction end point is controlled by measuring the acid value, saponification value, and hydroxyl value. After meeting the requirements, it can be filtered and packaged to become the finished product of acetylated monolaurin citrate. The conversion rate is 94.6%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com