Nickel-manganese composite hydroxide particles, method for producing same, positive electrode active material for nonaqueous electrolyte secondary batteries, method for producing positive electrode active material and nonaqueous electrolyte secondary dell

A technology of composite hydroxide and positive electrode active material, which is applied in the direction of non-aqueous electrolyte batteries, secondary batteries, nickel compounds, etc., can solve the problems of high particle size uniformity, battery capacity reduction, and selective degradation of fine particles, and achieve industrialization Effect of high value, high particle size uniformity, and excellent battery characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0278] [Manufacture of composite hydroxide particles]

[0279] Composite hydroxide particles were produced as follows. In addition, various special grade chemicals manufactured by Wako Pure Chemical Industries, Ltd. were used in producing the composite hydroxide particles, the positive electrode active material, and the secondary battery in all the examples.

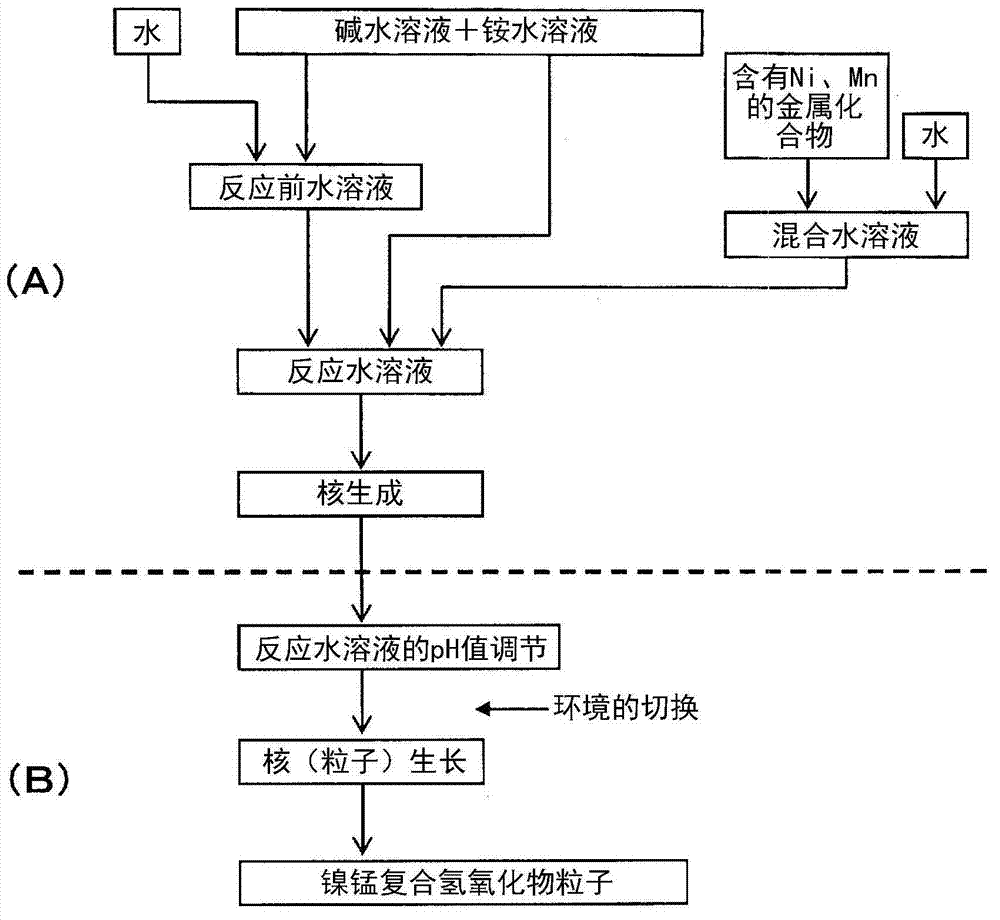

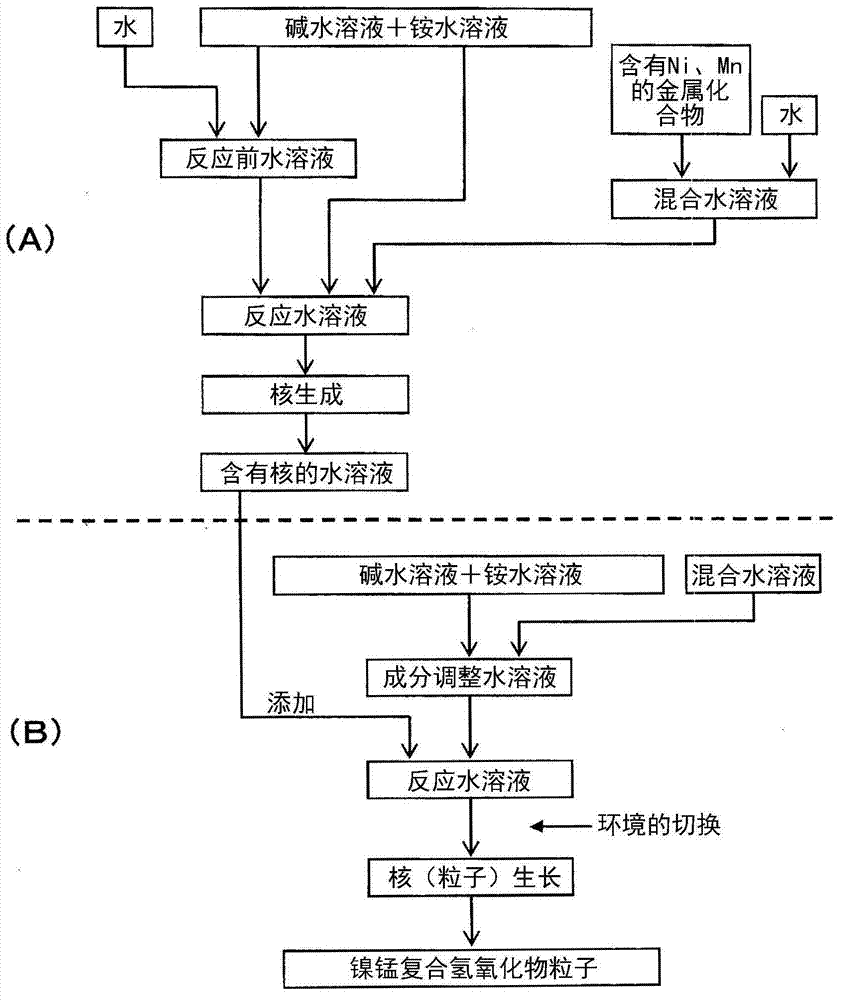

[0280] (nucleation process)

[0281] First, water was filled to half the capacity of the reaction tank (34 L), and the temperature in the tank was set to 40° C. while stirring. At this time, an atmospheric environment was formed in the reaction tank (the oxygen concentration was 21% by volume). By adding an appropriate amount of 25% by mass aqueous sodium hydroxide solution and 25% by mass ammonia water to water in the reaction tank, the pH of the reaction liquid in the reaction tank was adjusted to 13.0 based on a liquid temperature of 25°C. Furthermore, the ammonia concentration in this reaction liquid was adjusted ...

Embodiment 2)

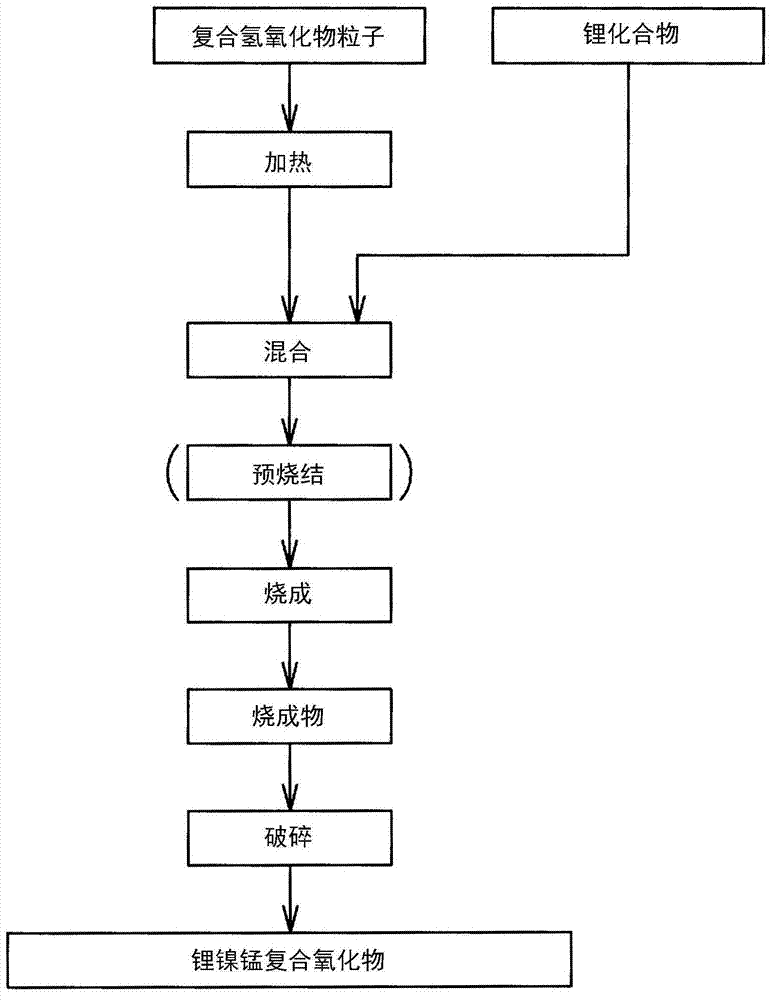

[0320] Except mixing lithium hydroxide and composite oxide particles so that Li / Me=1.25, and setting the firing temperature to 850° C., the same procedure as in Example 1 was carried out to obtain a positive electrode active material for a non-aqueous electrolyte secondary battery. , and evaluated. The composition of the obtained positive electrode active material was 8.84% by mass of Li, 29.9% by mass of Ni, and 28.0% by mass of Mn, and it was confirmed that Li 1.25 Ni 0.50 m 0.50 o 2 .

Embodiment 3)

[0322] Except that in the particle growth process of the composite hydroxide particle production process, the switching from the atmospheric environment to the nitrogen gas environment is performed at a time point of 6.25% of the total time of the particle growth process, the operation is performed in the same manner as in Example 1, and a non- A positive electrode active material for an aqueous electrolyte secondary battery was developed and evaluated. In addition, the composition of the obtained composite hydroxide particle and the positive electrode active material is the same as that of Example 1, and the composite hydroxide particle is composed of a center part and an outer shell part similarly to Example 1, wherein the center part is made of needles. shaped fine primary particles (particle diameter about 0.3 μm), and the shell portion is composed of plate-shaped primary particles (particle diameter 0.7 μm) larger than the fine primary particles on the outside of the centr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com